VCI Film For Multimetals

1. VCI Film anti rust film adopts advanced VCI film For Steel technology, suitable for black, non-ferrous and multi-metal combination packaging, providing comprehensive and long-lasting anti rust film protection effect.

2. Stretch film and anti rust film is easy to stretch and seal, suitable for various special-shaped or large parts, improves packaging efficiency, and is widely used in industrial anti-rust needs.

3. VCI film anti rust film has passed REACH, ROHS, SGS and many other international certifications.

- CVCI

- China

- 14 days after payment

- 1500 tons per month

- Information

Product overview of stretch film:

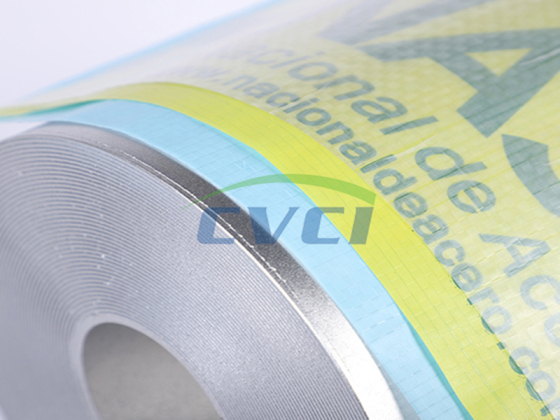

Our VCI Film For Steel is a high-performance anti-rust packaging material that continuously releases non-toxic and odorless VCI vapor phase rust inhibitors, quickly forms a molecular protective layer in a closed environment, effectively adheres to the metal surface, and prevents oxidation and corrosion. Compared with traditional packaging materials, this stretch film not only has excellent anti-rust performance, but also can be directly used in subsequent processing such as spraying and welding without cleaning after the metal products are taken out. We provide a variety of anti rust film and stretch film to meet the diverse metal packaging needs of parts, machined parts, steel coils, etc. The product supports customized sizes and functional additives, such as anti-ultraviolet, anti-static, acid gas resistance, etc., and is an ideal anti-rust solution for the steel industry during storage and transportation.

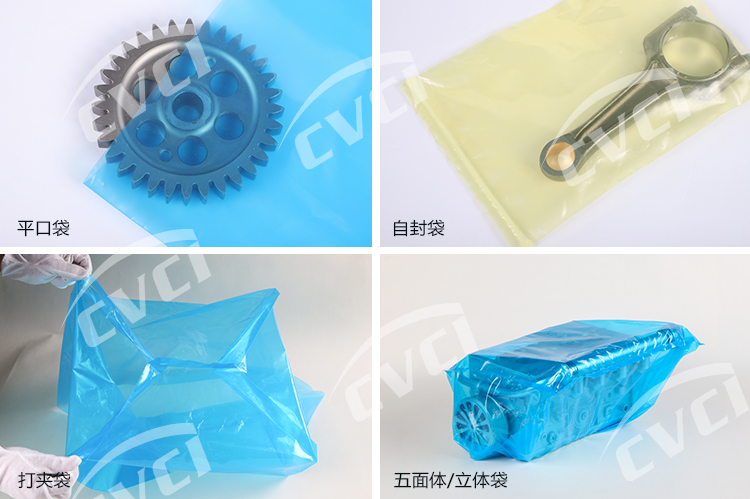

Product model of anti rust film: SF/HF

Product form of anti rust film: Bags, rolls, slices and gusset.

Features of stretch film:

Effective anti-corrosion and packaging are completed simultaneously to improve efficiency

Metal parts can be used or assembled right out of the box without cleaning

VCI film, anti rust film and stretch film are available in a variety of formulas and sizes

Provide reliable VCI Film For Steel anti-rust protection for steel products

VCI film stretch film contains at least 10% recycled plastic, which complies with environmental regulations and sustainable development goals

VCI film materials are recyclable, contributing to green packaging solutions

Protection material of stretch film:

Our VCI Film For Steel is specially designed to provide reliable corrosion protection for a wide range of ferrous materials, including carbon steel, alloy steel, cast iron, cast steel, and powder metallurgy components. By releasing effective vapor-phase corrosion inhibitors, this VCI film forms a protective molecular layer on metal surfaces, making it an ideal anti rust film for both storage and transportation. Whether used as stretch film or custom packaging, it ensures clean, contact-free protection for steel products in various industrial environments.

Scope of application of stretch film:

VCI Film For Steel is mainly used for antirust packaging of ferrous metal parts in industries such as automobiles, machine tools, electric power equipment, heat exchange systems, and hardware tools. As a high-performance VCI film and anti rust film, it provides effective vapor-phase protection during storage and transportation. It can also be used as stretch film for wrapping large components or customized into bags and sheets, offering versatile and clean corrosion protection solutions across multiple industrial applications.

Usage method of VCI film:

After the metal parts are cleaned and dried, wrap the VCI Film For Steel as soon as possible, and determine the amount of VCI Film For Steel or add other antirust materials according to different materials and the size of packaging space. Anti rust film can be used together with antirust paper as cushion to realize oil-free export anti-rust packaging.

Packaging and storage of VCI film:

Clean and dry the metal equipment, or put it into the VCI plastic film packaging bag after oil treatment and drying, and seal after removing the excess air in the bag. The sealed metal surface shall be free of residual sweat, water film, acid and alkali or other dirt and rust. Unless otherwise stated and verified, VCI materials cannot generally be used in optical devices and products of highly explosive substances and associated propellants.