Safe VCI Film For Polymetals

1. VCI plastic VCI stretch film is suitable for a variety of metals such as steel, copper, aluminum, etc., with comprehensive protection.

2. VCI plastic VCI filmdoes not contain nitrite, is non-toxic and harmless, and is friendly to operators and the environment.

3. VCI plastic provides up to 24 months of high-efficiency anti-corrosion protection, making transportation and storage safer.

- CVCI

- China

- 14 days after payment

- 1500 tons per month

- Information

Product overview of VCI stretch film and VCI film:

VCI stretch film does not contain nitrite, phosphate and amine substances, and is mainly used for rust prevention of metal products such as steel, iron, aluminum, aluminum alloy, copper, silicon steel, phosphating, galvanized sheet, tin plate, color-coated sheet, etc. VCI stretch film is safe and environmentally friendly, and its safety meets the EU ROHS directive and REACH regulations, and meets the German TRGS615 and TRGS900 technical specifications.

Application range of VCI film:

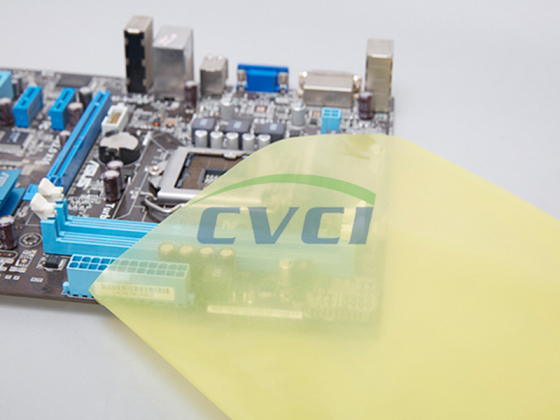

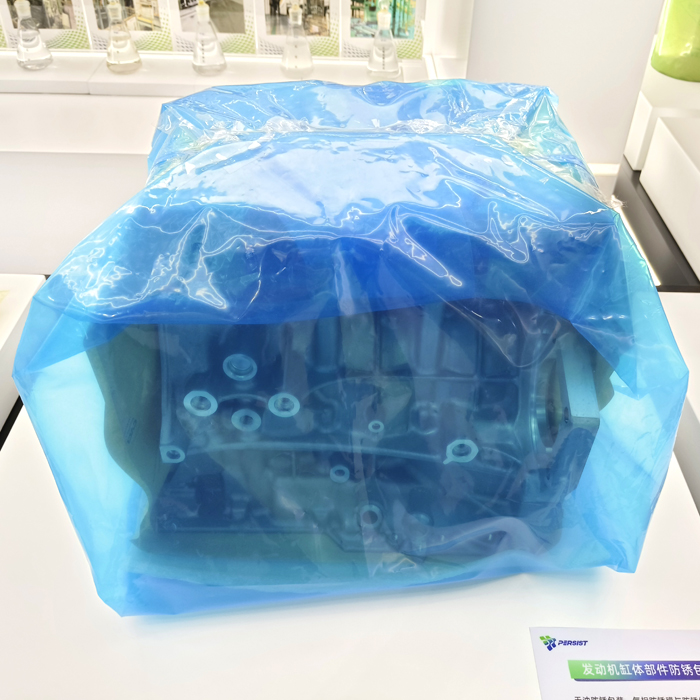

VCI Film For Polymetals is an environmentally friendly anti-rust film designed for the protection of various metals. It is suitable for various metal materials such as steel, iron, aluminum, copper, silicon steel, phosphating metal, galvanized sheet, tin plate and color-coated sheet. VCI plastic Safe VCI Film is widely used in metal parts anti-rust packaging in many industries such as metallurgical manufacturing, military equipment, mechanical processing, automotive parts, electronic equipment, hardware tools, etc. VCI plastic Safe VCI Film can be used for long-distance transportation and long-term storage. VCI plastic Safe VCI Film can form a lasting vapor phase protective layer without contacting the metal surface, effectively inhibiting oxidation reactions, preventing rust, and ensuring the quality stability and safety of metal products in different environments.

Features of VCI plastic Safe VCI Film:

The VCI plastic Safe VCI Film For Polymetals we produce does not contain nitrites, phosphates and amine compounds, making it safer to use. The raw materials of the product have been strictly screened and will not release harmful gases. It is suitable for use in confined spaces or crowded places.

VCI plastic Safe VCI Film For Polymetals has passed the multiple environmental and health requirements of the EU ROHS Directive and REACH Regulations, and meets the German TRGS615 and TRGS900 technical specifications. It is suitable for global export and meets the safety and environmental protection requirements of many countries.

VCI plastic Safe VCI Film For Polymetals has excellent anti-rust properties for ferrous metals (such as steel and iron) and non-ferrous metals (such as copper, aluminum, and alloy materials). It can be widely used in product packaging with various complex material combinations, and the protection effect is stable and long-lasting.

The VCI stretch film produced by us does not require additional oiling, is easy to use, and has an anti-rust period of up to 1 to 2 years. It is suitable for the protection needs of metal products during long-term storage or long-distance transportation.

Product form of VCI plastic VCI film:

To meet the needs of different packaging scenarios, our VCI plastic Safe VCI Film For Polymetals series products provide a variety of specifications and forms, which are flexibly applicable to the rust protection of various metal products:

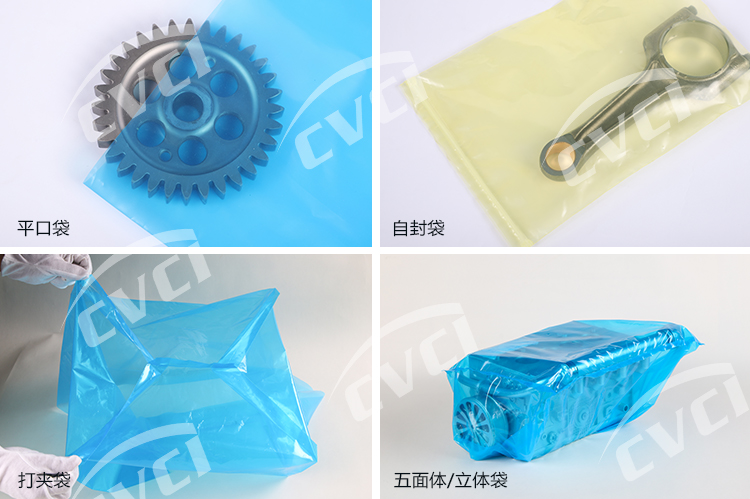

Flat bag (safe VCI film bag)

VCI plastic Safe VCI Film is suitable for single-piece packaging of small and medium-sized parts. It is easy to operate and has a simple seal. It is often used for packaging mechanical parts and electrical parts.

Three-dimensional bag (VCI gusset bag)

VCI plastic Safe VCI Film has strong three-dimensional space support and is suitable for packaging metal parts with irregular shapes or large volumes, such as motors, molds, etc.

Clamp bag (VCI clamp bag)

VCI plastic Safe VCI Film is easy to open and seal repeatedly. It is suitable for packaging semi-finished products or spare parts for maintenance that need to be taken frequently. It is rust-proof and practical.

Self-sealing bag (VCI ziplock bag)

VCI plastic Safe VCI Film has strong sealing performance and is suitable for electronic devices and precision hardware accessories with high requirements for cleanliness and airtightness, and provides more stringent protection.

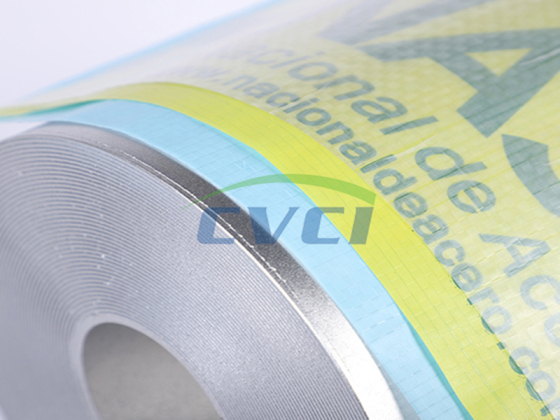

VCI stretch film / VCI film roll

VCI plastic VCI stretch film can be cut to any size, suitable for mass production on production lines or pallet wrapping, which improves packaging efficiency. It is a commonly used anti-rust material in the metallurgical and auto parts industries.

VCI plastic safe VCI film sheet

VCI plastic VCI stretch film can be used as a spacer or surface covering, suitable for stacking protection of parts or short-term anti-rust covering of the outer surface of equipment.

Our VCI plastic safe VCI film For Polymetals support multi-size customization and can be used with automatic packaging equipment to meet the anti-rust packaging needs of different customers in storage, transportation, packaging, sealing, etc. Whether you need single-piece protection or batch logistics packaging, Safe VCI Film For Polymetals is your trustworthy choice.

Our Outstanding Laboratory:

CVCI is more than just a manufacturer; we're a technical partner to our customers. Our laboratory team continuously optimizes the formulations of our anti-rust paper, anti-rust film, and anti-rust oil based on customer feedback. Each improvement is backed by rigorous laboratory testing. This ensures our products remain competitive in the market.

How to use VCI Film For Polymetals:

When using Safe VCI Film VCI stretch film or related VCI film For Polymetals products, to ensure the anti-rust effect, it is recommended to thoroughly clean and dry the metal equipment first, and apply oil protection if necessary. After the surface is completely dry, put it into the VCI stretch film packaging bag. When packaging, try to exhaust the excess air of VCI stretch film to ensure the sealing and avoid moisture or oxygen residue affecting the performance of the vapor phase corrosion inhibitor. The sealed metal surface should be free of sweat and alkali substances or rust marks to ensure that the VCI stretch film can play the best protective performance. Unless specially verified, VCI film For Polymetals are not suitable for the protection of optical instruments, highly explosive items and their connecting devices.

Partners:

We understand that VCI film isn't just a part of packaging; it's crucial to ensuring the quality of our customers' products. CVCI's rust prevention technology has been highly recognized by companies like GM, Dongfeng, and NGC. In practical collaborations, we've helped customers reduce rust during transportation while optimizing overall packaging costs. This mutually beneficial partnership model is a key reason for CVCI's widespread popularity.

Honors:

CVCI boasts over 80 patents, seven national key new products, and 12 specialized and special new products, collectively comprising its prestigious honors. These achievements are the result of innovative exploration in rust prevention products. Our customers can directly experience the protective effects of our VCI plastic VCI stretch films, VCI stretch film VCI film and oils, a testament to our commitment to innovation.

Why is our VCI Film For Polymetals coating particularly suitable for Southeast Asian customers?

In Southeast Asian countries like Vietnam, Malaysia, and the Philippines, manufacturing and export industries are highly developed, especially in steel processing, hardware components, aluminum profiles, and motor parts. Local businesses often face environmental challenges such as humidity, high temperatures, and salt spray during cross-border transportation, thus requiring higher standards for Safe VCI Film rust protection compared to other markets. Our VCI plastic VCI Film For Polymetals multi-metal rust-protective film is very mature in the Southeast Asian market. Safe VCI Film maintains stable vapor phase protection even in high humidity environments, effectively preventing rust and corrosion on metal parts even after sea freight, warehousing, or long waiting periods for distribution.

Furthermore, considering the diverse product range of Southeast Asian customers, we support customized Safe VCI Film packaging in various specifications, sizes, and bag types. Whether it's steel coils, profiles, hardware components, complete machine parts, or spare parts packages for export, we can provide suitable VCI stretch film packaging solutions. More importantly, our VCI plastic VCI stretch film is free of harmful components such as nitrites and amines, complying with international environmental regulations such as RoHS and REACH, ensuring peace of mind for companies exporting to Europe, America, Japan, and South Korea.

In environments where local temperatures often exceed 30°C and humidity exceeds 80%, our Safe VCI Film performs reliably in actual use, effectively reducing transportation losses and repair costs. It also reduces the cleaning hassles associated with traditional oil-based rust prevention, making the packaging process easier and cleaner.