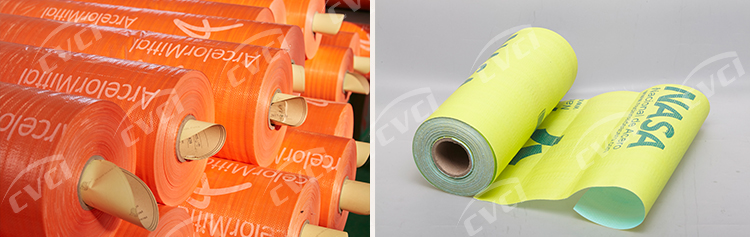

Fabric Reinforced VCI Film

1. VCI PP Woven Fabric combines woven fabric structure, is tear-resistant and puncture-resistant, and is suitable for heavy-duty packaging.

2. VCI reinforced stretch film uses VCI technology + all-plastic material, is non-toxic and recyclable, and complies with ROHS and REACH standards.

3. VCI PP Woven Fabric VCI film is suitable for packaging of a variety of metals and large equipment, and supports customized sizes and printing.

- CVCI

- China

- 14 days after payment

- 1500 tons per month

- Information

Product introduction of VCI film:

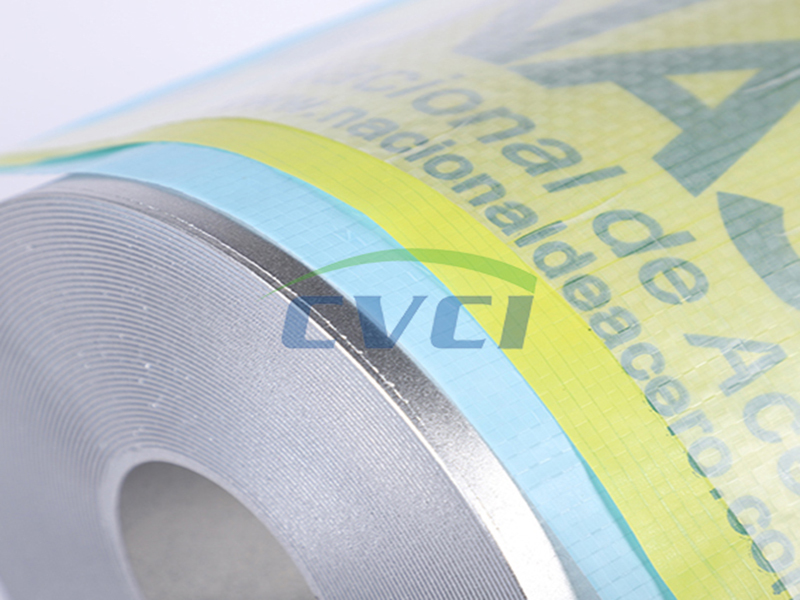

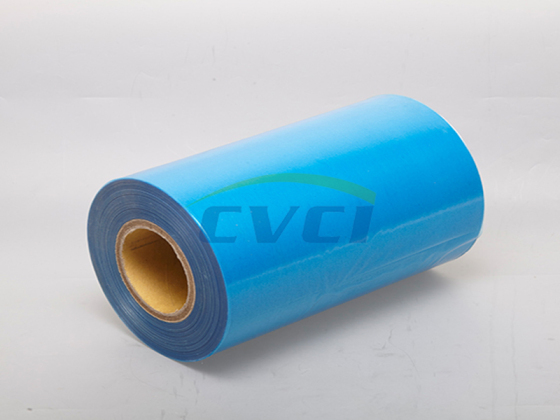

VCI film is a high-performance anti-rust material developed by our company CVCI patented by compounding highly effective protective VCI film with polyethylene or polypropylene woven fabric. It has a strong structure and long-lasting anti-rust, and is widely used in metallurgy and heavy equipment packaging. VCI film has excellent tear and puncture resistance and is a representative of reinforced VCI film. Common forms include VCI PP Woven Fabric and VCI reinforced stretch film, which are suitable for multi-metal protection.

Product model: SF/ZCF, SF/ZLF

Product Features of VCI PP Woven Fabric:

The reinforced VCI film we produce meets international environmental standards, is non-toxic, recyclable, green and safe. It has the advantages of tear resistance, puncture resistance, high strength, and strong weather resistance. It can be printed and customized according to customer needs. Some models of VCI PP Woven Fabric VCI film can be used as VCI reinforced stretch film, which takes into account both winding and anti-rust protection. It is an ideal material choice for multi-metal composite packaging. We also support customized services, including the width, length, thickness, color, anti-rust time of reinforced VCI film, and customer LOGO printing. If you have more needs for VCI film, please feel free to contact our team.

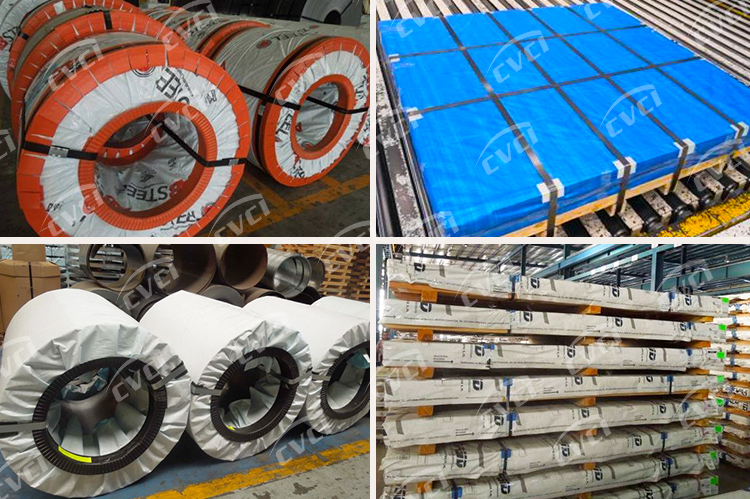

Application range of VCI PP Woven Fabric VCI film:

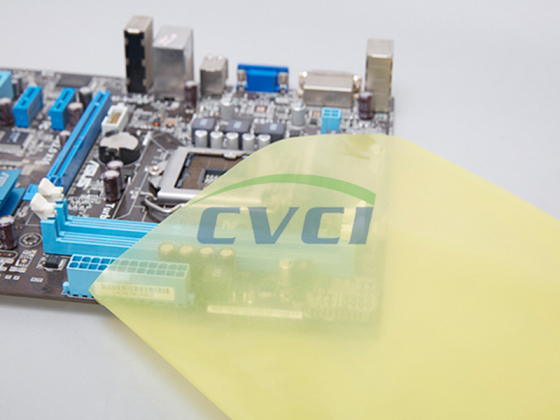

The reinforced VCI film we produce is widely used in the anti-rust packaging of metal materials in the metallurgical field, and is suitable for cold plate, galvanized plate, tin plate, coated steel plate, copper plate, aluminum plate and strip and other metal products. The product adopts high-strength VCI PP Woven Fabric structure, combined with VCI film with excellent anti-rust performance, which can effectively resist moisture and oxidation during storage and transportation, and extend the service life of metal. Some models can also be used as VCI reinforced stretch film, which is suitable for wrapping packaging of large equipment and is an ideal anti-rust packaging material for multi-metal industries.

Usage method of VCI reinforced stretch film:

Fabric Reinforced VCI Film can directly replace fabric reinforced antirust paper for steel coil packaging. The packaging method is the same as that of anti-rust paper. Remove the plastic film sleeve outside the antirust paper.

Matters needing attention:

1. Avoid the damage of the VCI film during the packaging process, especially the inner core and outer periphery of the steel coil.

2. Try to exhaust excess air before sealing during packaging.

3. Ensure the tightness of the overall package.

4. The ambient humidity at the site shall not exceed 85% when packaging.

5. Because the plastic film is easy to generate static electricity, the cleanliness of the packaging should be guaranteed and the working environment should be clean.

6. Requirements shall be put forward during transportation and loading and unloading to avoid damage of packaging materials.

Packaging and storage:

Fabric Reinforced VCI Film should be stored in a cool and dry warehouse, 150 mm above the ground, away from heat sources, to avoid chemical pollution and corrosive gas invasion, and to avoid damage to the original packaging; After unsealing, the remaining VCI plastic that cannot be used up at one time shall be sealed and kept again; The shelf life of Fabric Reinforced VCI Film is one year from the date of delivery.

Our Customers:

CVCI's extensive customer partnership network demonstrates our extensive industry influence. From traditional steelmakers like Baowu Steel and Angang Steel to high-tech companies like Huawei and new energy vehicle giants like BYD and Tesla, our anti-rust paper, anti-rust oil, and anti-rust film have all played a role. This diverse application scenario is a testament to the strength of our products.