- Home

- >

- Products

- >

- VCI Heat Shrink Film

- >

VCI Heat Shrink Film

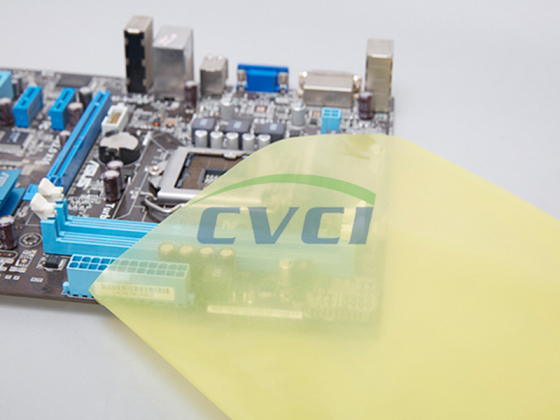

1. Heat Shrink Film has good antirust function for ferrous metals, copper, aluminum and other metals, as well as anti-aging and anti-static properties, which can provide body fitted antirust packaging protection for various packaged materials.

2. Heat Shrink Film is used for long-term antirust packaging of various metal equipment and large equipment such as metallurgy, military industry, machinery, auto parts, electronics, hardware, etc.

3. Anti Rust Heat Shrink Film can fit items tightly and protect metal from rusting for a long time.

- CVCI

- China

- 14 days after payment

- 1500 tons per month

- Information

Product introduction of VCI film:

Anti Rust Heat Shrink Film has good anti-rust function for ferrous metals, copper, aluminum and other metals. It also has anti-aging and anti-static properties, and can provide skin-fitting anti-rust packaging protection for various packaged items. Anti Rust Heat Shrink Film can be used for long-term anti-rust packaging of various metal equipment and large equipment such as metallurgy, military industry, machinery, auto parts, electronics, hardware, etc.

Performance characteristics of VCI film:

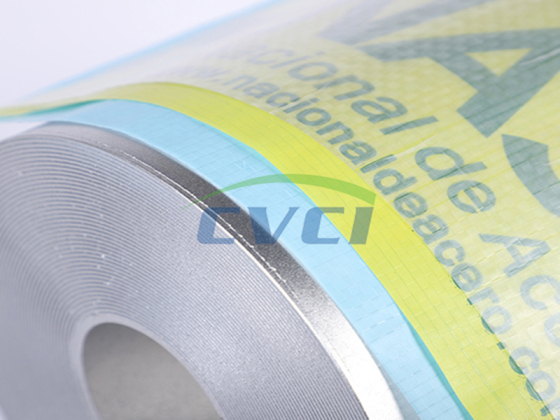

VCI film is made of multi-metal vapor phase anti-rust masterbatch and LDPE resin extrusion blow molding. It has good anti-rust function for ferrous metals, copper, aluminum and other metals, and also has anti-aging and anti-static properties. VCI film can provide skin-fitting anti-rust packaging protection for various packaged items.

Application range of VCI film:

VCI film is widely used in anti-rust packaging of various metal materials, and is suitable for various metals and surface-treated products such as steel, iron, aluminum, copper, silicon steel, phosphated plate, galvanized plate, tin plate, color-coated plate, etc. As a high-performance Anti Rust Heat Shrink Film, VCI film can fit the surface of the product tightly after shrinking, forming a highly sealed protective layer, effectively isolating moisture and corrosion factors.

VCI film is widely used in protective packaging in industries such as metallurgical equipment, military parts, hardware tools, etc., and is particularly suitable for comprehensive protection of metal materials during export packaging, long-term storage and sea transportation. Heat shrink film or VCI film solutions can be selected to meet the VCI Shrink Film Wrap packaging and anti-rust requirements in different application scenarios.

Long-term Partner:

Providing rust protection for Fortune 500 companies is a testament to CVCI's strength. Our customized protection solutions for clients like BMW, Dongfeng, and Weichai, rigorously validated in labs and backed by real-world feedback, have helped them resolve their long-standing rust problems. Choosing CVCI means choosing peace of mind.

How to use VCI film:

Use VCI Shrink Film Wrap to seal large equipment. Use sheet VCI Shrink Film Wrap to splice on site to package the equipment as a whole, then heat shrink it and attach it to the equipment. When sealing the equipment, make the VCI Shrink Film Wrap into a packaging bag, put the equipment into the bag, and then heat shrink it. The degree of shrinkage is that the VCI film is tightly attached to the spare parts.

FAQs of VCI Shrink Film Wrap:

Q: What is VCI film?

A: VCI film is a film that combines shrink wrap and vapor phase rust inhibitor (VCI) functions. After heating, the film tightly wraps the product while releasing VCI molecules, forming an invisible protective layer on the metal surface to prevent rust.

Q: What is the difference between heat shrink film and ordinary VCI Shrink Film Wrap?

A: Ordinary shrink film only provides dust and moisture protection, while Anti Rust Heat Shrink Film also provides long-lasting rust protection, making it particularly suitable for the transportation and long-term storage of metal products.

Q: Does Anti Rust Heat Shrink Film require additional rust prevention oil?

A: No. VCI film inherently provides rust prevention, eliminating the tedious steps of oiling and cleaning, making it cleaner and more environmentally friendly.

Q: What products are suitable for VCI film?

A: VCI film is widely used for packaging metal products such as steel coils, steel pipes, large machinery and equipment, automotive parts, and electronic components, especially for export and ocean shipping.

Q: How long does the rust prevention effect of VCI film last?

A: Under normal sealing and reasonable use conditions, VCI film can provide 6 months to 24 months of anti-rust protection, the specific time depends on the product characteristics and storage environment.

About us:

With a strong global presence, CVCI exports a full range of anti-corrosion products—such as VCI film, VCI Shrink Film Wrap, and powder—to over 40 countries and regions, including Mexico, South Korea, Malaysia, and Spain. Our reliable VCI Shrink Film Wrap packaging solutions have been widely recognized for protecting metals, contributing to the global manufacturing and logistics supply chain.