Reinforced Aluminum Plastic Composite VCI Film

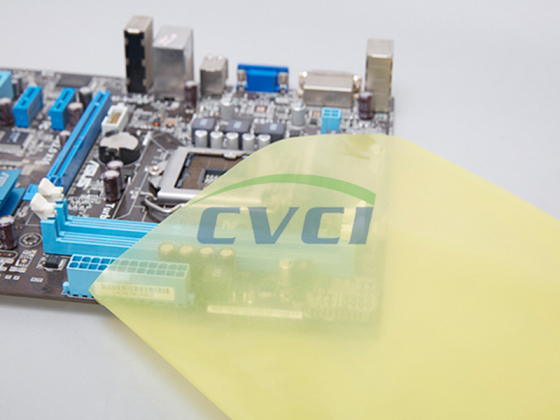

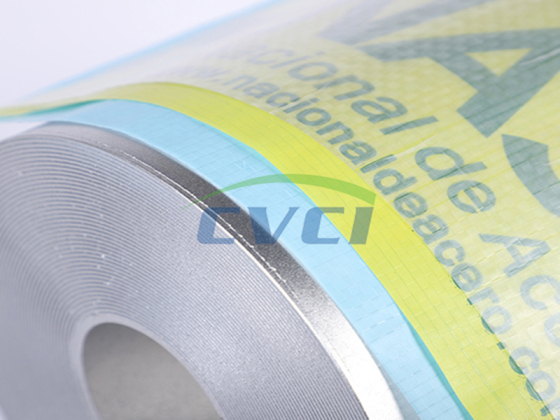

1. Reinforced Aluminum Plastic Composite VCI Film is made of aluminum plastic VCI film, fabric reinforcement material and anti rust VCI film multi-layer composite material.

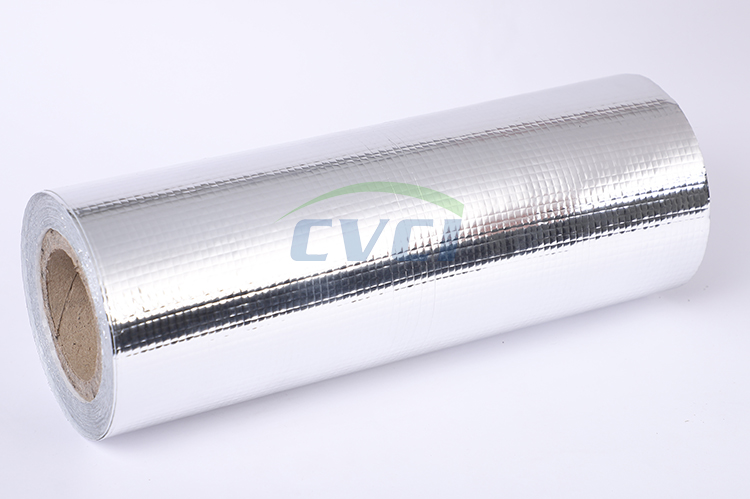

2. Reinforced VCI Aluminum Foil film has high barrier, high strength, anti-aging, anti shielding, anti rust and other properties, and Aluminum plastic VCI film can realize continuous hot sealing operation.

3. VCI film Composite film can customize thickness, size, color and bag type to meet various industrial packaging needs.

- CVCI

- China

- 14 days after payment

- 1500 tons per month

- Information

Product introduction Aluminum plastic Composite film:

Aluminum plastic Composite film is a multi-layer composite material composed of aluminum-plastic film, fabric reinforcement material and anti-rust film. It has high barrier, high strength, anti-aging, anti-shielding, anti-rust and other properties, and can achieve continuous heat sealing operation. Aluminum plastic Composite film is suitable for anti-rust protective packaging of various machine tools, large military equipment, textile equipment, printing and packaging equipment, rubber and plastic processing equipment, compressors, engines and other large electromechanical equipment and components.

Product model of VCI film: SF/DZ, SF/HZ

Product advantages of VCI film:

Reinforced VCI Aluminum Foil film is a composite film made of aluminum plastic film, VCI anti-rust film and reinforced fabric. It has many advantages. It can block water vapor and air well and protect metal from rust. The material is very strong and not easy to tear. It can also resist sunlight and is suitable for long-term use. VCI reinforced stretch film can be sealed continuously with a heat sealer and is suitable for automatic packaging. Reinforced VCI Aluminum Foil film is not only moisture-proof and rust-proof, but also can withstand friction and pulling during transportation. It is an ideal choice for packaging metal products (such as equipment parts, mechanical accessories, etc.).

Application range of VCI reinforced stretch film:

Composite film is widely used in various large electromechanical equipment and precision parts that require long-term anti-rust protection, such as CNC machine tools, large military equipment, textile machinery, printing and packaging equipment, plastic processing machinery, compressors, diesel engines and their parts, etc. Composite film can form a stable anti-rust barrier (Anti-rust packaging) during transportation and storage, effectively preventing moisture, oxygen and corrosive gases from invading. Composite film is very suitable for static storage, long-distance transportation and sea transportation packaging, especially for full coverage and sealing of large equipment through heat shrink packaging (VCI shrink film), improving packaging strength and overall safety.

How to use VCI reinforced stretch film:

Apply buffer protection to the sharp edges, protrusions or easily worn parts of the equipment (foam, plastic corners and other materials can be used) to prevent puncture or wear of the anti-rust film during transportation.

Use suitable anti-rust packaging materials, such as VCI film, VCI shrink film, or Aluminum plastic composite bags. Choose the corresponding size according to the volume and shape of the equipment.

Place the processed electromechanical products firmly on the VCI film, or directly into the packaging bag.

Use Composite film to completely cover the equipment, or tighten the bag mouth, try to expel air, and ensure that a closed anti-rust space is formed. Use heat sealing equipment to weld the interface. The welding width is recommended to be controlled between 15-25mm to ensure the sealing effect.

Product form of VCI film:

The main forms of Reinforced VCI Aluminum Foil film are bag type (mainly in the form of three-dimensional cover), sheet type, and roll type.

FAQ of VCI film:

Q: What metals can VCI reinforced stretch film VCI film protect?

A: VCI reinforced stretch film is suitable for a variety of metals, including carbon steel, stainless steel, cast iron, copper, brass, aluminum and its alloys, and has a broad spectrum of vapor phase rust prevention capabilities.

Q: Is VCI film Aluminum plastic Composite film heat-sealable? Is the seal firm?

A: VCI film Aluminum plastic Composite film supports heat sealing technology, the recommended heat sealing temperature is 140℃~160℃, and the sealing width is recommended to be controlled at 15-25mm, which can achieve a firm seal.

Q: Can VCI film VCI reinforced stretch film be customized in different colors, thicknesses or sizes?

A: Yes. We provide customized colors of VCI film (such as silver gray, blue, and white), thickness (0.08mm~0.2mm), width, and bag type can all be customized according to customer needs.

Q: Is VCI film Reinforced VCI Aluminum Foil film suitable for export transportation packaging?

A: Yes, VCI film has high barrier properties and good physical strength, which is suitable for long-distance transportation and export wooden box packaging, and VCI film can effectively resist moisture and corrosive gases in the shipping environment.