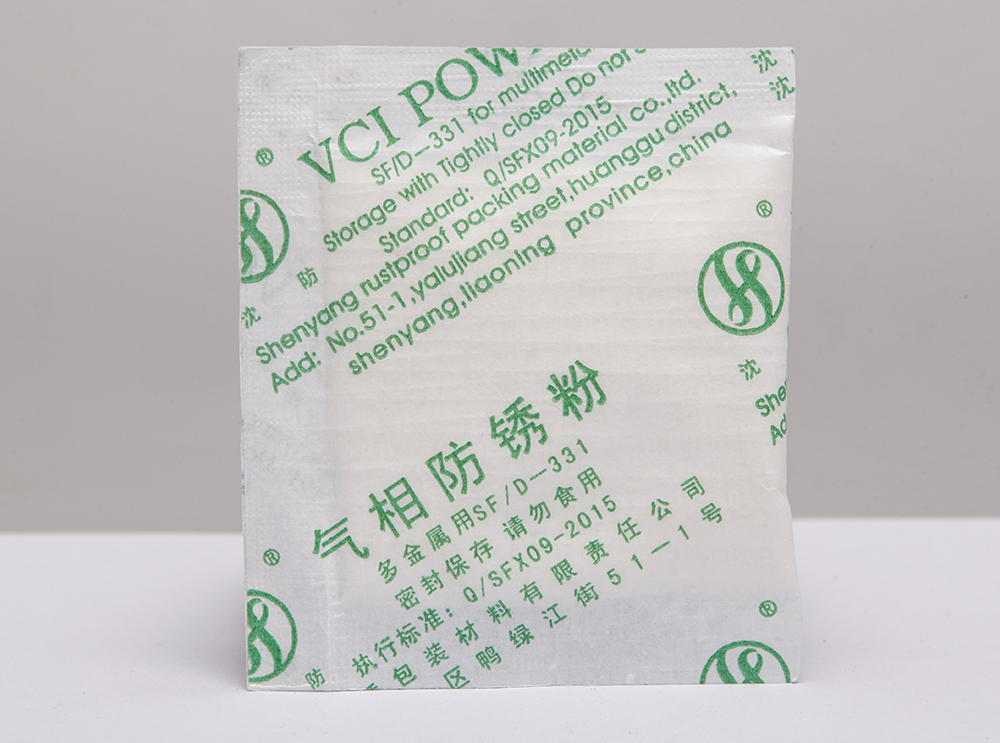

VCI Powder For Polymetal has excellent gasification, diffusion and adsorption properties. After the powder is vaporized, it is adsorbed on the protected metal surface to form a protective layer, which can effectively prevent the corrosion of the metal surface, especially applicable to the rust prevention of the metal surface that is difficult to reach, such as deep holes, thin pipes, twists and cracks.

PRODUCT DESCRIPTION

VCI powder for polymetal SF / d331l has excellent gasification, diffusion

and adsorption properties. After the powder is gasified, it is a dsorbed

on the metal surface to form a protective layer, which can effectively

prevent the corrosion of the metal surface.

1. It is especially suitable for the rust prevention of hard to reach metal surfaces such as deep holes, slender pipes, twists and gaps SF / d331l has excellent gasification, diffusion and adsorption properties.

2. After the powder is gasified, it is adsorbed on the metal surface to form a protective layer, which can effectively prevent the corrosion of the metal surface. It is especially suitable for the rust prevention of hard to reach metal surfaces such as deep holes, slender pipes, twists and gaps

3. Suitable for

Ferrous metals, copper and its alloys, aluminum and its alloys

USAGE METHOD

The protected metal surface shall be free of rust, oil stain,sweat, dust, moisture and other impurities.

Place the anti rust bag in the protected space and keep it sealed. The effective working distance is 30cm.The protection period can reach 12 months, generally the usage of every 1m ³ of confined space is 100g, which can be increased or reduced according to the packaging materials,construction environment humidity and storage and transportation conditions.

The formed VCI protective layer generally does not need to be removed before processing or use. If necessary, it is easy to remove it with air gun or water.

Notes:

The surface of the protected workpiece shall be clean and dry. When using VCI materials, pay attention to sufficient dosage. When sealing and packaging, desiccant can be used together.

The placement and hanging of large products shall be evenly distributed, and the distance between VCI powder and metal surface shall be less than 30cm.

The tubular workpiece shall be evenly distributed in the inner cavity.Holes and pipes protected with VCI materials shall be firmly sealed

During the sealing and packaging of large products, pay attention to the sealing of the packaging to prevent acute angles and edges from piercing the sealing layer. Pay attention to the adaptability of VCI powder to paint and rubber parts

Clean and covered transportation tools shall be used for the transportation of VCI powder. Rain, snow and direct sunlight shall be p revented. Handle with care to avoid damaging the protective packaging layer.

The storage of VCI powder shall not damage the original protective packa ging layer and keep it sealed. Store in a cool, dry and clean warehouse.

Avoid direct placement on the ground or direct sunlight. It shall not be stored together with chemicals. It shall be no less than 1m away from the heat source and no less than 0.1M away from the ground.

Take it and use it at any time. If it cannot be used up at one time, it shall be re sealed and stored.