- Home

- >

News

From a practical project perspective, Antistatic VCI Film is ideal for any equipment containing exposed or semi-exposed metal parts.

While antistatic vci film is easy to use, some details are still worth paying attention to.

Circuit boards may encounter various accidents on their journey from the factory to the customer, including high temperatures, humidity, salt spray, static electricity, and friction.

If you would like to learn more about China Safe VCI Film, please continue to follow our website.

China Safe VCI Film is a polyethylene film containing a gaseous rust inhibitor. This gaseous rust inhibitor prevents iron metals from rusting.

Many companies assume that the warehouse environment in machining centers is good, but during the rainy season, humidity can soar to 80% or 90%. Within days, a fine oxide layer can appear on machined aluminum alloy parts.

Can China anti rust film replace traditional desiccant boxes and desiccants in such humid warehouses?

Now more and more export companies choose VCI steel wrap to protect steel, so why do more and more export companies choose VCI steel wrap to protect steel? Let's take a look together!

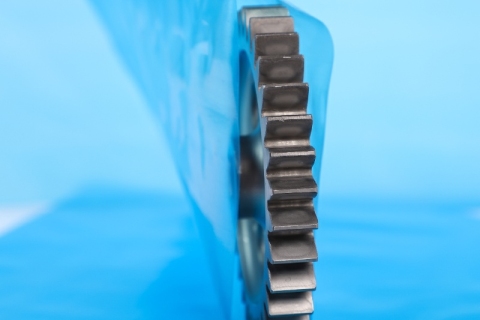

Wind turbine gears are highly valuable and require extremely high machining precision. Corrosion, if it occurs, directly impacts the equipment's lifespan and operating efficiency.

CVCI can also provide customized services, which can adjust the parameters of the safe VCI film according to the size and shape of the sensor.

Metal surface corrosion is particularly problematic during long-term storage, cross-border transportation, or humid environments. Choosing the right rust prevention solution for this large equipment is crucial.

But our safe VCI film is different. It can be applied to a variety of metals such as steel, copper, and aluminum.