What Rust Proof Materials Are Suitable for Circuit Boards?

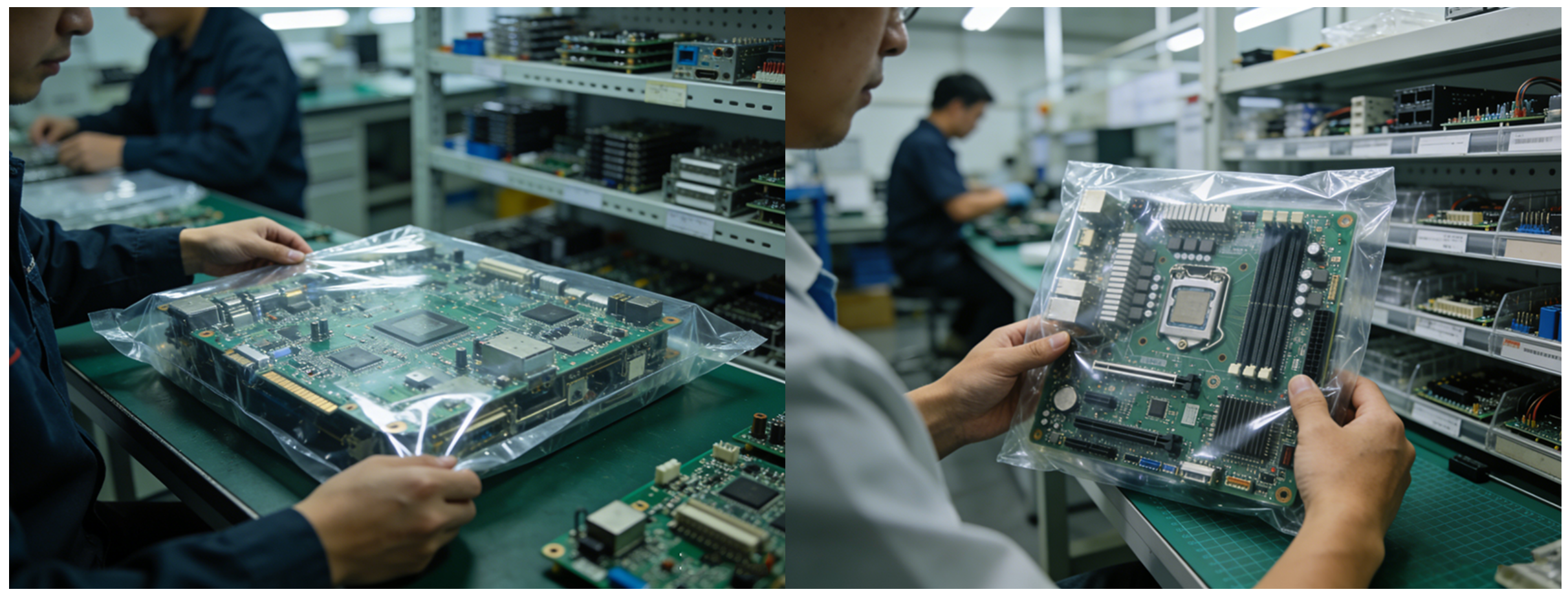

2025-12-12 10:23Circuit boards may encounter various accidents on their journey from the factory to the customer, including high temperatures, humidity, salt spray, static electricity, and friction. This is especially true for export businesses, where the maritime environment places even higher demands on the corrosion resistance of circuit boards. Therefore, the most suitable rust-proofing material has become a growing concern. Based on feedback from more and more companies engaged in PCB export business, the industry is gradually reaching a consensus—China Safe VCI Film is currently one of the most stable and reliable rust-proofing methods.

I. Why is rust prevention essential for circuit boards?

For PCBs, rust is far more than just metal corrosion. Copper, tin, and other metals in the solder pads and circuits of circuit boards are very prone to oxidation, especially in environments with humidity, temperature differences, or salt spray. If an oxide layer appears on the surface, it will not only affect soldering but may also cause problems such as cold solder joints, unstable conductivity, and abnormal impedance. Even a seemingly small oxidation point can render the circuit board unusable.

Temperature differences during transportation also have a significant impact. Imagine this: the factory packaging temperature is 20°C, truck transport cools to 10°C, then suddenly rises to 40°C in the shipping container, and finally returns to a humid 32°C after unloading. This alternating temperature fluctuation creates invisible condensation on the circuit board surface, and this moisture is the biggest driver of metal corrosion. This is especially true for exports to Southeast Asia, where air humidity is consistently close to 80% or even 90%, and the salt content of the sea air is alarmingly high. Many customers report that if protective measures are not taken thoroughly, oxidation marks can be seen within days.

CVCI, as a manufacturer with many years of experience in the rust prevention industry, has partnered with buyers from dozens of countries and regions and has extensive export experience. Through this experience, we have come to understand that China Safe VCI Film is a more suitable method for rust prevention of circuit board products.

II. How Effective is China Safe VCI Film?

Previously, the understanding of rust prevention was largely limited to "applying rust-preventive oil." However, for electronic products, oil-based contact rust prevention is not only troublesome but also affects subsequent soldering and has high cleaning costs. Therefore, China Safe VCI Film has gradually become the mainstream method in recent years.

China Safe VCI Film's core technology lies in its volatile rust inhibitor (VCI). These molecules slowly evaporate within the sealed packaging, evenly coating the metal surface to form an invisible yet highly stable protective layer. This layer blocks corrosion from moisture, oxygen, and salt, offering a more proactive and comprehensive protection than simply relying on desiccants or moisture-proof bags. Furthermore, China Safe VCI Film provides non-contact protection, preventing solder pad contamination. The protective molecules automatically dissipate upon opening the packaging, without affecting solder performance – a crucial factor for many electronics manufacturers.

China Safe VCI Film's industry testing data is also very compelling. Products wrapped in China Safe VCI Film were placed in simulated high humidity (95%) and temperature variations (20℃–45℃) environments for 60 days, resulting in no oxidation spots on the solder joints. During approximately 30 days of sea freight to Southeast Asia, the surface electrical properties of the copper foil remained stable. Even in stacked packaging with gaps, China Safe VCI Film's VCI molecules still penetrate into corners, protecting the entire packaging space. China Safe VCI Film produced with CVCI typically also includes electrostatic discharge (ESD) protection, directly solving the two most troublesome problems during transportation: static electricity and oxidation. Therefore, both testing data and feedback from export customers demonstrate that China Safe VCI Film's effectiveness has stood the test of time.

III. Why Primarily Use China Safe VCI Film?

Many factories have compared various rust prevention methods, but ultimately unanimously chose China Safe VCI Film. The reason is simple: it's convenient, clean, low-cost, and stable.

A comparison makes it even clearer. While rust-preventive oils offer strong rust protection, they can contaminate solder joints, requiring cleaning, affecting processes, and increasing odors and environmental concerns during transportation; desiccants, though inexpensive, only passively absorb moisture and are ineffective against salt spray; aluminum-plastic bags enhance moisture protection but cannot actively resist oxidation. Rust-preventive films combine active protection, sealing effects, and ease of use, requiring no cleaning and not affecting soldering, making them the most valuable "friendly rust prevention method" in the electronics industry.

China Safe VCI Film is particularly suitable for large-volume transportation, such as companies exporting large quantities of PCBs, stacked packaging, and palletized loading. It occupies little space, packs quickly, and is compatible with various methods such as cartons and vacuum bags. Many of CVCI's customers in the high-humidity regions of Southeast Asia previously used China Safe VCI Film as their standard packaging material. After prolonged use, they were unwilling to switch to other methods, leading to long-term partnerships with us.

IV. Why is CVCI's VCI Film a long-term purchaser in Southeast Asian factories?

In recent years, CVCI's VCI Film exports have grown rapidly, especially in Southeast Asian countries such as Malaysia, Indonesia, the Philippines, Vietnam, and Thailand. These regions are humid year-round, have a high concentration of electronics manufacturing, and face significant transportation pressures, making them heavily reliant on rust-preventive products. The main reason Southeast Asian customers are willing to continue purchasing is that the effectiveness, delivery time, and quality of our VCI Film meet their needs.

CVCI's VCI Film provides 12–24 months of long-term protection, making it particularly suitable for long-term storage by sea. It fully complies with international standards such as SGS, RoHS, and REACH, is non-toxic and odorless, and completely safe for electronic components. For the electronics industry, its anti-static properties have been enhanced for safer transportation. Furthermore, our factory has stable production capacity, can customize different specifications, thicknesses, and colors, and can even provide brand logo printing. Even large-volume engineering orders can be shipped quickly and have stable shipping schedules, which is especially important for export customers.

If you require rust prevention for circuit board products or other products, please feel free to contact us at cvci-gaoxiu@chinavci.com for professional advice on rust prevention products.