Can VCI Stretch Film Protect the Sensor from Oxidation?

2025-10-06 11:09The sensor can easily be oxidized when it is stored, transported or idle, which affects the accuracy and service life of the product. Can VCI stretch film protect the sensor from oxidation? The VCI stretch film we produce can effectively protect the sensor from oxidation and will not cause damage to the sensor.

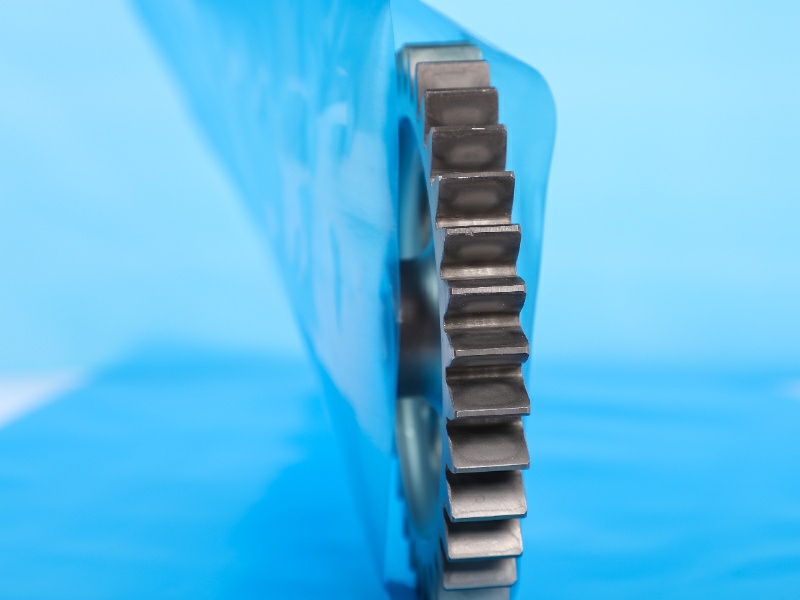

The sensor is not large in size, and the protection of ordinary anti-rust methods may not be in place, or the parts may be easily damaged. Coated with anti-rust oil, the oil film may penetrate into the inside of the sensor and affect the normal operation of the circuit. With ordinary plastic film, it can only isolate dust and still oxidize and rust. Our VCI stretch film can release gas phase anti-rust components. These components will form a protective barrier on the metal surface of the sensor. Oxidation can be prevented without direct contact with the components. It will not pollute the internal structure of the sensor, but also fully cover the metal parts and get comprehensive protection.

Our VCI stretch film has a wide range of applications, and metal products such as steel, iron, aluminum, aluminum alloy, copper, silicon steel, phosphate sheet, galvanized sheet, tinplate, color coated sheet, etc. can be protected. Moreover, our VCI stretch film does not contain nitrites, phosphates and amines, is non-toxic and harmless, and is friendly to operators and the environment. When workers in the production workshop wrap the sensor, they do not need to wear heavy protective gloves or worry about exposure to harmful substances.

Our VCI stretch film can provide efficient corrosion protection for up to 24 months. The entire process of the sensor from the completion of production to delivery, transportation, and customer reception may take several months. The long-term protection of our VCI stretch film can ensure that it will not be oxidized during this period of time. In addition, our safe VCI film safety has also passed a number of international certifications, in line with the EU ROHS directive and REACH regulations, and also in line with the German TRGS615 and TRGS900 technical specifications, VCI Stretch Film even if it is exported to countries and regions with strict environmental protection requirements, it can pass the test smoothly.

CVCI can also provide customized services, which can adjust the parameters of the safe VCI film according to the size and shape of the sensor. If the sensor is small in size and has many precision bumps, we can customize a thinner and more flexible film to ensure that the safe VCI film can closely fit the surface of the sensor and will not squeeze the parts because the safe VCI film is too thick. And we have a professional safe VCI film production line, from the melting of raw materials, film blowing and forming to cutting and rolling, the whole process is automatically controlled, and the thickness and transparency of the film can be maintained at a stable level. If the customer has an urgent order and needs to customize safe VCI film in large quantities, we can adjust the production plan to ensure that it can be delivered on time.

Whether it is a small electronic sensor or a special sensor in the automotive and medical fields, it is very suitable to choose our safe VCI film for anti-rust protection. Comprehensive protection, safety and environmental protection, long-lasting durability, and can be customized according to demand, so that the sensor has always maintained a good performance state in the whole process of production, storage, transportation, and inventory. If you are interested in our safe VCI film, please feel free to contact us!