What Is the Safest Rust Prevention Method for Storing Steel Plates?

2025-12-29 16:05Why is rust prevention essential for steel plates during storage?

Many people still believe that steel plates only rust when exposed to water, but reality is far more complex. As long as there is moisture and oxygen in the environment, coupled with temperature changes, electrochemical reactions can occur on the steel plate surface. Especially in warehouses, diurnal temperature fluctuations can cause condensation to form on the steel plate surface. This water film, often imperceptible to the naked eye, is a major cause of corrosion.

For steel plates stored for extended periods, the risk comes not only from the environment but also from time itself. The longer the storage period, the higher the probability of corrosion. Once corrosion occurs, it not only affects the appearance but can also impact thickness accuracy, welding quality, and even lead to customer rejection. Rust prevention is a fundamental safety measure in steel plate storage.

Are common steel plate rust prevention methods truly reliable?

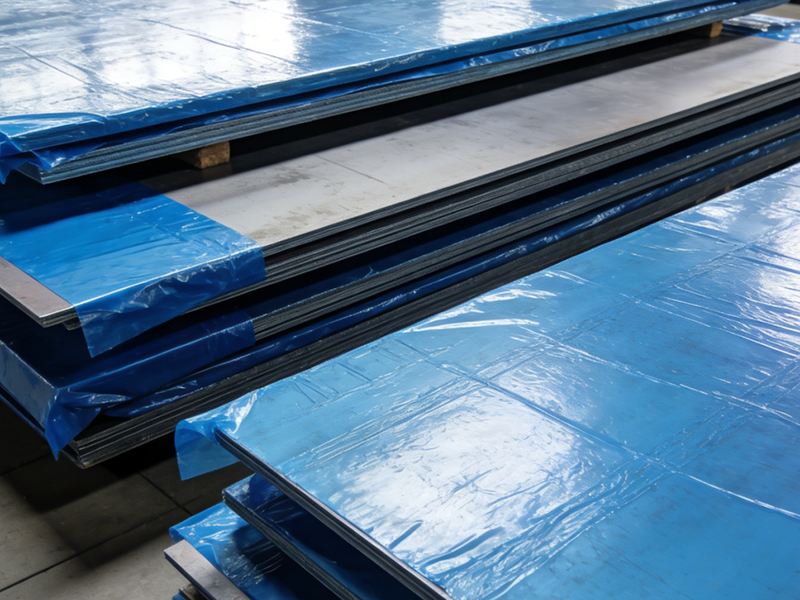

In practice, many companies have tried different rust prevention methods, such as applying rust-inhibiting oil, coating with rust-inhibiting wax, covering with ordinary plastic film, or simply dehumidifying the warehouse. These methods are not entirely ineffective, but each has significant limitations. While rust-inhibiting oil provides strong protection, its use on steel plates often incurs cleaning costs, requiring degreasing before subsequent processing; ordinary plastic film only isolates dust and offers almost no active protection against moisture and condensation; and warehouse dehumidification equipment primarily improves the overall environment, but the risk remains if the equipment malfunctions or during extreme weather conditions. It is against this backdrop that more and more companies are beginning to focus on a more convenient and stable solution – VCI.

What are the practical effects of using VCI rust-inhibiting film for steel plate rust prevention?

Many customers, when first encountering VCI, have the biggest question: can it really prevent rust without applying oil or other coatings?

The answer is yes, and in long-term steel plate storage scenarios, the effect is often very noticeable. Steel plates packaged with VCI film remain dry and clean even after months of storage in high-humidity environments, without rust spots or water stains.

More importantly, after unpacking, there is no oil film or wax residue on the steel plate surface, allowing for direct entry into cutting, stamping, welding, and other processes, greatly reducing pre-processing steps. This is especially beneficial for manufacturing companies.

What is the main working principle of VCI rust-inhibiting film?

The true core of VCI anti-rust film lies not in the film itself, but in the VCI molecules. During the manufacturing process, vapor-phase corrosion inhibitors are uniformly incorporated into the film. These inhibitors slowly volatilize in enclosed or semi-enclosed packaging spaces, forming a stable anti-corrosion atmosphere. The anti-corrosion molecules automatically adsorb onto the steel surface, forming an extremely thin, invisible protective layer. This protective layer effectively blocks direct contact between oxygen and moisture and the metal, while simultaneously inhibiting corrosion reactions. Even if the steel surface has minor scratches or imperfections at the edges, a relatively uniform protective effect is achieved.

Simply put, VCI anti-rust film doesn't just block rust; it prevents rust from occurring at its source.

What are the advantages of antistatic VCI film produced by CVCI?

In our actual collaborations, we have found that different steel plate specifications and storage periods require significantly different anti-corrosion solutions. Therefore, when producing antistatic vci film, we focus on adaptability and stability.

Whether it's thin plates, thick plates, bundled steel plates, or single-sheet packaging, we can match the appropriate anti-corrosion grade and film thickness based on storage period and transportation conditions. Currently, our anti-rust film has been exported to multiple countries and regions, with the Southeast Asian market showing continuous growth, and the application feedback in high-humidity environments is very stable.

What other details should be noted when using antirust VCI film?

While antistatic vci film is easy to use, some details are still worth paying attention to. For example, ensuring the steel plate surface is dry and clean before packaging can significantly improve the anti-corrosion effect; during long-term storage, minimizing frequent unpacking helps maintain the anti-corrosion atmosphere; in extremely humid environments, using a desiccant in conjunction with the film provides extra protection.

These seemingly simple steps can often provide an extra layer of security for anti-corrosion.

From the perspective of actual application results, antistatic vci film has found a very good balance between safety, stability, and ease of use. It doesn't add complex processes, doesn't affect subsequent processing, yet provides continuous protection for steel plates during long-term storage and in complex environments.

For companies that want to reduce the risk of corrosion and improve inventory quality, antistatic vci film is no longer an optional solution, but an increasingly mature and trustworthy anti-corrosion method. If you are also troubled by long-term storage of steel plates, rust risks, or anti-corrosion issues during export transportation, feel free to contact CVCI. Based on your steel plate type, storage period, and target market, we can help you find the most suitable antistatic vci film. If possible, we also welcome you to visit our factory to see our anti-rust film production process and practical application cases. Face-to-face communication often makes it easier to find the most suitable and hassle-free solution.