Is It Mandatory to Use Antistatic Vci Film for Packaging Exported Equipment?

2025-12-31 16:26Many pieces of equipment don't have quality issues, but fail due to poor packaging.

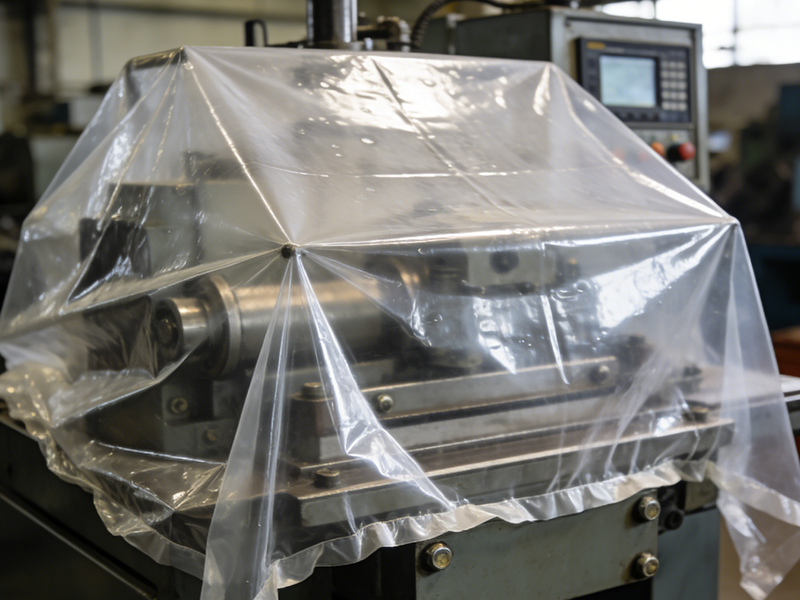

In the export equipment industry, a frustrating situation often arises: the equipment is perfectly fine during factory acceptance testing – function, precision, and appearance are all good – but when the customer receives it, they find signs of corrosion. In mild cases, the surface is discolored; in severe cases, it affects assembly and use.

Why are exported equipment particularly prone to rusting?

Many companies don't have very high anti-rust requirements for domestic deliveries because the transportation cycle is short and the environment is relatively controllable. However, the situation is completely different when it comes to exports. Sea shipping can take weeks or even months, and containers repeatedly experience temperature changes between the sea and ports. High temperatures during the day and cooling at night cause the water vapor in the container to constantly condense, evaporate, and re-condense. This process is very damaging to metal. Even if the equipment surface doesn't directly contact water, rust is difficult to avoid if moisture is present for a long time. More realistically, many export destinations are in high-temperature and high-humidity regions such as Southeast Asia, South Asia, and the Middle East, where the air humidity is inherently high. If the packaging protection is inadequate, the risk is quickly amplified once the equipment arrives at the port.

What are the practical effects of using Antistatic VCI Film for exported equipment?

After packaging, the anti-rust film continuously releases anti-rust factors. These molecules form an extremely thin protective layer on the equipment surface, blocking oxygen and moisture from participating in the corrosion reaction. This protection remains effective even during long-term sea shipping, port delays, or storage at the destination. For the customer, the equipment surface is clean and non-greasy after unpacking, requiring no additional cleaning, and can be directly installed or debugged. This is especially important for the export of automated equipment, precision machinery, and electrical equipment.

What is the main working principle of VCI anti-rust film?

Within the packaging space, the VCI components in the anti-rust film slowly volatilize, diffuse evenly, and automatically adsorb onto the metal surface. This adsorption forms a molecular-level protective layer that does not affect dimensions or assembly, but effectively inhibits corrosion. Even if the equipment structure is complex, with internal cavities, gaps, or blind holes, vapor-phase anti-rust can cover areas that are difficult to reach with traditional oiling, which is crucial for the anti-rust protection of complete machines.

Which exported equipment is more suitable for using VCI anti-rust film?

From a practical project perspective, Antistatic VCI Film is ideal for any equipment containing exposed or semi-exposed metal parts. Examples include mechanical equipment, automated production line modules, pump and valve systems, motors, electrical control cabinets, and engineering equipment components. Especially for equipment requiring export and immediate use upon unpacking, VCI anti-corrosion film is one of the most cost-effective and lowest-risk anti-corrosion solutions currently available. In the Southeast Asian market, this packaging method has been widely accepted and even incorporated into the packaging specifications of many end customers.

What are the advantages of CVCI's Antistatic VCI Film in export?

Through extensive export experience, we have encountered various complex transportation and storage scenarios. These real-world cases have driven us to continuously optimize the stability and adaptability of our Antistatic VCI Film products. We can provide anti-corrosion film solutions in different specifications and anti-corrosion grades based on equipment volume, packaging method, and transportation cycle. Currently, our anti-corrosion products have been exported to multiple countries and regions, with the Southeast Asian market being the most mature in its application. Its performance in high-humidity and high-temperature environments has also been proven over the long term.

If you are hesitant about the anti-corrosion packaging solution for your exported equipment, or are unsure whether your product is suitable for VCI anti-corrosion film, please feel free to contact us. CVCI can help you clarify the anti-corrosion solution based on your equipment type, transportation method, and export market. If time permits, we also welcome you to visit our factory.