- Home

- >

- Products

- >

- VCI Paper For Copper

- >

VCI Paper For Copper

1. VCI Paper For Copper produced by CVCI is suitable for copper and copper alloys, can effectively prevent rust and discoloration, and is widely used in the electronics and electrical industries.

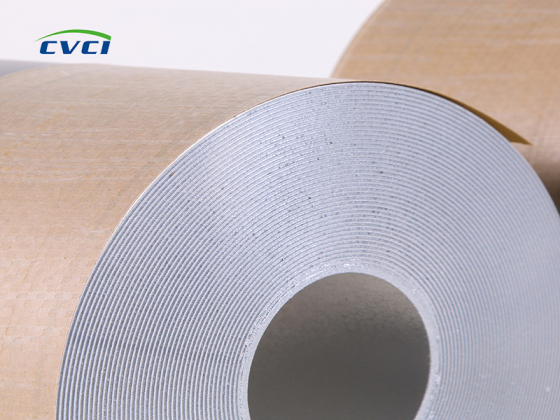

2. The surface of VCI Paper For Copper produced by CVCI is composited with PE film, which is waterproof and moisture-proof. Different composite layers can also be customized according to customer needs.

3. VCI paper adopts a sulfur-free formula with independent formula technology, which is non-corrosive to copper materials and safer.

4. Packaging paper has a long-lasting anti-rust effect and is suitable for long-term storage and transportation environments.

- CVCI

- China

- 14 days after payment

- 1500 tons per month

- Information

Introduction of VCI paper:

Packaging paper is a new type of high-efficiency protective material. It uses a specific VCI anti-rust component to evenly impregnate ordinary neutral base paper or wrinkled neutral base paper to form a long-lasting and stable anti-rust protective layer on the surface of the paper. VCI paper is compounded with a layer of PE (polyethylene) film on the surface of the paper, which not only makes the paper have good waterproof and moisture-proof functions, but also effectively blocks the damage of water vapor and other corrosive gases in the air to metal. The structural design of VCI paper not only retains the flexibility and wrapping properties of the base paper, but also improves the comprehensive protective performance of the packaging material. It is widely used in the packaging of various copper and copper alloy products with high requirements for rust and moisture resistance.

Product models of packaging paper:

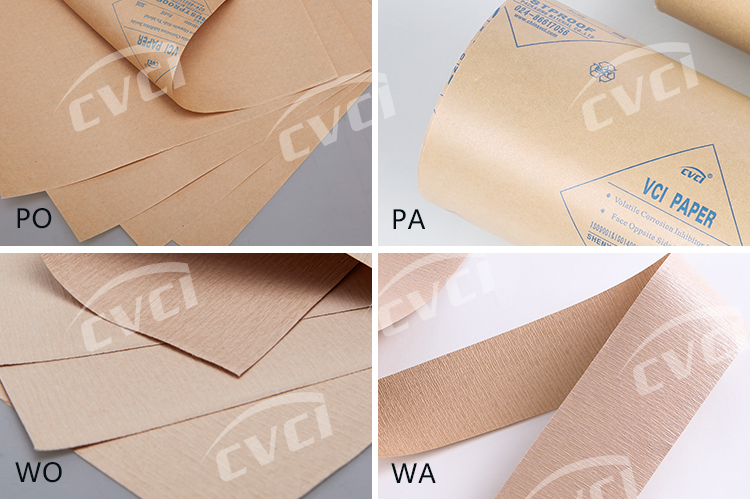

VCI paper sets different product models according to different application requirements. Its standard model is SF/T502-□□, which is specifically divided into four structural categories: PO type, WO type, PA type, and WA type, which can meet the actual needs of different rust prevention, moisture resistance, strength and adaptability. Among them, PO and PA structure products are usually suitable for small or medium-sized copper parts packaging with higher requirements for dimensional accuracy and coating effect, while WO and WA structures are more suitable for large parts or scenes that require higher physical strength protection.

Common specifications of VCI paper for copper:

The packaging paper for copper we produce has a variety of specifications to meet the diverse needs of different customers in packaging and rust prevention. The standard width specifications of VCI paper for copper are 787mm and 1050mm, mainly PO and PA structures, suitable for the packaging of small and medium-sized copper parts, such as electronic components, electrical accessories, etc., which are convenient for cutting and batch use.

For scenarios that require larger format packaging, we also provide 1575mm wide VCI paper for copper, which adopts WO and WA structures.

In addition, we also support VCI paper for copper customized specification services, including length, gram weight, number of structural layers, etc., which can be flexibly adjusted according to the specific application scenarios of customers.

VCI paper for copper protection objects:

Packaging paper for copper is specially designed for copper and its alloy products. Whether it is pure copper parts, copper alloy parts, or steel-based copper-plated products, as long as VCI paper for copper is used correctly, it can effectively prevent oxidation, corrosion, discoloration and other problems during a long storage or transportation period. This is mainly because VCI paper for copper contains a vapor phase corrosion inhibitor formula specially developed for copper materials, which can form a micron-level dense protective film on the metal surface to prevent oxygen, water vapor, and pollutants in the air from contacting the copper material.

Product application of VCI paper:

Antirust protection of copper and copper alloy parts in electronic and electrical industries.

Usage method of packaging paper:

After the metal parts are cleaned and dried before storage and transportation, the single full-cover packaging can be used (the use area of the VCI packaging paper is approximate to the metal surface area), or the overall packaging paper can be used by using the vapor phase antirust paper as the lining and isolation cushion. However, if the outer VCI paper for copper package is not waterproof, it is recommended to use composite PE packaging paper and then seal it with adhesive tape.

Storage of packaging paper for copper:

Packaging paper should be stored in a dry and cool place and sealed to avoid damage to the original package. The shelf life is three years from the date of delivery.

About us:

CVCI's VCI paper, VCI film, VCI masterbatch, VCI powder and other products are exported to more than 40 countries and regions including the United States, Italy, Spain, Turkey, Malaysia, Singapore, Japan, South Korea, Mexico, etc., and have established a global marketing network, which has been recognized by global customers and has contributed to the revitalization of national industry.