VCI Paper For Polymetal

1. We can provide printing services according to customer requirements and customize personalized PolymetallicVCI Paper for Multimetals for customers.

2. VCI Anti Rust Paper is Oil-Free & Acid-Free.

3. VCI Anti Rust Paper is a kind of Powerful Vapor Corrosion Inhibitors For Ferrous, Non-ferrous & Multimetal Parts.

- CVCI

- China

- 14 days after payment

- 1500 tons per month

- Information

Product Introduction of VCI Anti Rust Paper:

VCI Anti Rust Paper is suitable for the anti-rust packaging of various metal assemblies, and has a good balanced protection effect on materials such as steel, copper and copper alloys, aluminum and aluminum alloys, galvanized passivated steel plates, and tinned steel plates. Polymetallic VCI Paper for Multimetals uses a neutral substrate that will not cause electrochemical reactions, ensuring that there is no corrosion crosstalk between multiple metals. It is widely used in metallurgy, military industry, machinery, auto parts, electronics, electrical engineering, hardware and other industries. As an environmentally friendly and efficient VCI Anti Rust Paper, also known as Polymetallic VCI paper, it is an ideal choice for the anti-rust packaging of multi-material parts.

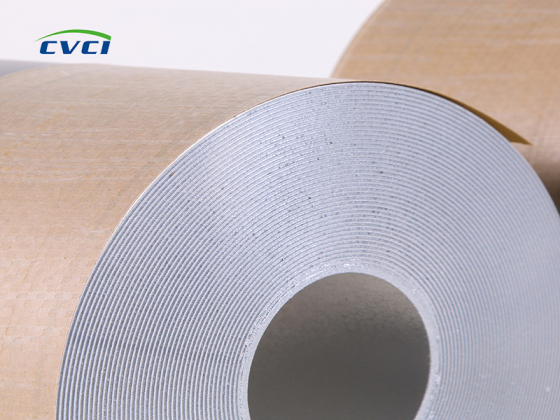

Product form of Polymetallic VCI Paper for Multimetals:

| Composition structure | Function description |

| VCI (vapor corrosion inhibitor) | Release corrosion inhibition molecules to form an anti-rust protective layer on the metal surface to prevent rust. |

| Plain or wrinkled base paper | As a VCI carrier, it provides a basic packaging support structure. |

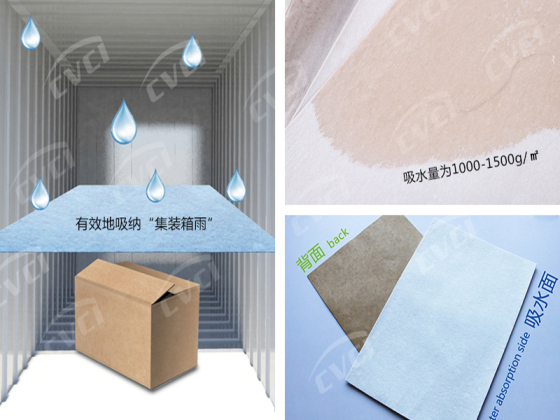

| PE composite layer | Enhance the waterproof and moisture-proof properties of the product, suitable for export and long-term storage environment. |

| Printing customization service | Provide pattern, logo and other printing according to customer needs to create a personalized VCI Anti Rust Paper packaging solution. |

Product Details of Polymetallic VCI paper:

The common specifications of our VCI anti-rust paper include widths of 787mm and 1050mm (for PO and PA structures), and widths of 1575mm (for WO and WA structures). The length and weight can be customized according to customer needs to adapt to different packaging methods. As an efficient Polymetallic VCI Paper for Multimetals, this product has excellent and balanced anti-rust protection for various metal assemblies such as steel, copper and copper alloys, aluminum and aluminum alloys, galvanized passivated steel plates, tinned steel plates, etc., and will not produce electrochemical reactions. Polymetallic VCI paper is especially suitable for long-term protective packaging of complex structural parts. VCI Anti Rust Paper is widely used in metallurgy, military industry, machinery manufacturing, auto parts, electronics, electrical engineering, hardware and other industries. It is an ideal choice for Polymetallic VCI paper.

How to use Polymetallic VCI Paper for Multimetals:

After cleaning and drying the metal parts before storage and transportation, you can use single fully covered packaging (the area of the vapor phase anti-rust paper is similar to the surface area of the metal), or you can use the whole packaging method by using Polymetallic VCI Paper for Multimetals as the inner lining and isolation cushion. However, if the outer packaging is not waterproof and sealed, it is recommended to use composite PE gas VCI Anti Rust Paper and seal it with tape.

How to store and keep VCI Paper for Multimetals:

Polymetallic VCI paper should be stored in a dry and cool place and sealed to avoid damage to the original packaging. The shelf life of VCI Anti Rust Paper is three years from the date of manufacture.

Our High-Quality Laboratory:

Rust prevention isn't just a piece of paper or a barrel of oil; it's a systematic solution. Our CVCI laboratory is equipped with over 100 pieces of testing equipment, enabling us to evaluate material performance and verify its application. For example, when evaluating a roll of VCI paper, we must not only consider its rust-proofing effectiveness but also its environmental suitability. Our attention to detail ensures our customers' confidence.

Long-term Partners:

CVCI's customer base spans multiple industries, making our rust prevention products highly adaptable. From export packaging of steel materials to overseas shipping of automotive parts, we offer proven solutions. The continued trust of over 8,000 customers gives us confidence to expand into the future.

About us:

CVCI always adheres to the development concept of "green, safe and sustainable". In the research and development and production of VCI anti-rust products, it actively adopts recyclable and non-toxic formulas and vigorously promotes the promotion and application of environmentally friendly packaging materials. We not only pay attention to the anti-rust effect of products, but also pay attention to their impact on the environment and the safety of users. All anti-rust paper, anti-rust film, anti-rust liquid and other products comply with international environmental standards such as RoHS, REACH, SGS, etc., and are widely used in automobiles, electronics, military industry, exports and other industries with strict environmental protection requirements.