- Home

- >

- Products

- >

- Clean Type VCI Paper

- >

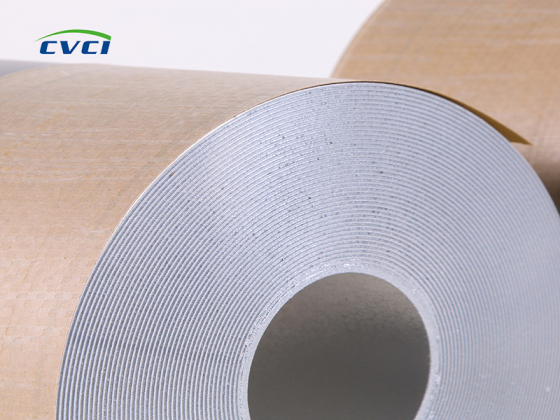

Clean Type VCI Paper

1. VCI packaging paper has excellent antirust performance.

2. Effectively prevent the VCI packaging paper dust and paper wool on the surface of the antirust paper from sticking to the surface of the steel plate.

3. Ensure the cleanliness of the VCI Kraft Packaging Paper, and realize the combination of antirust and cleanness.

4. VCI packaging paper can Effectively isolates air moisture and prevents metal rust.

5. Non-toxic and environmentally friendly, Anti-Rust Papersuitable for all types of metal packaging protection.

- CVCI

- China

- 14 days after payment

- 1500 tons per month

- Information

Product introduction of VCI packaging paper:

Corrosion Inhibiting Paper is a new type of paper-plastic composite antirust packaging material, which is composed of VCI, antirust base paper, polyethylene film and plastic woven cloth. Corrosion Inhibiting Paper characteristics are that compared with traditional VCI packaging paper, there is a layer of plastic insulation layer on the surface of the paper contacting the steel plate. After packaging, it can avoid paper wool and paper scraps sticking to the surface of the board, ensuring the cleanliness of the board, and it is suitable for products with high requirements for the cleanliness of the board, which is especially suitable for automobile outer plate packaging. The VCI packaging paper has excellent antirust function and water vapor barrier performance, high physical strength, good oil repellency, and has a certain moisture absorption compared with plastic film materials. VCI packaging paper can absorb moisture in the packaging space to reduce the relative humidity, reduce the risk of internal condensation, and reduce the impact of moisture on corrosion. It is currently the preferred material for cleaning packaging of metallurgical products.

Scope of application of VCI packaging paper:

Corrosion Inhibiting Paper and Anti-Rust Paper has a wide range of applications, especially for metal products in the metallurgical industry such as ordinary cold-rolled sheets, galvanized sheets, tin-plated sheets, chrome-plated sheets, oriented silicon steel, and non-oriented silicon steel. These metal materials have very high surface quality requirements during production and transportation, and any slight contaminants or surface scratches will affect subsequent processing and product performance. Our VCI packaging paper can solve this problem, so it is also suitable for high-standard demand scenarios such as automotive exterior panels, steel plates for home appliances, and steel plates for power equipment. The Anti-Rust Paper we produce is also suitable for packaging protection of the inner core of steel coils, which can effectively prevent rust or contamination of the metal surface caused by moisture penetration or paper scraps during transportation and storage. Corrosion Inhibiting Paper is also applicable to the packaging of metal products in cross-border transportation, long-term storage, or areas with high humidity.

Product usage of VCI packaging paper:

After the metal parts are cleaned and dried before storage and transportation, the single full-cover packaging can be used (the use area of the Anti-Rust Paper is approximate to the metal surface area), or the overall packaging can be used by using the VCI Kraft Packaging Paper as the lining and isolation cushion. However, if the outer Anti-Rust Paper package is not waterproof and sealed, it is recommended to use composite PE VCI Kraft Packaging Paper and then seal it with adhesive tape.

Storage of VCI Kraft Packaging Paper:

The sealed and packaged VCI Kraft Packaging Paper shall be stored in a cool, dry and rain-proof warehouse to avoid contact with moisture and direct sunlight on the ground, heat source, acid, alkali and other corrosive substances, and the distance from the ground shall not be less than 0.1m.

The storage environment temperature is lower than 40 ℃ and the relative humidity is lower than 85%.

Under the specified storage conditions, the shelf life of the product is 3 years from the date of delivery.

Why choose our Corrosion Inhibiting Paper?

Our Anti-Rust Paper not only maintains excellent anti-rust effect, but also increases the ability to prevent dust and Anti-Rust Paper scraps from contaminating, making it particularly suitable for applications with extremely high requirements for surface cleanliness. In addition, the Anti-Rust Paper we produce combines the dual protection mechanisms of vapor phase anti-rust and contact anti-rust, and also has good water vapor barrier properties and certain moisture absorption properties, reducing the risk of corrosion of metal products during transportation and storage. Anti-Rust Paper is safer and more reliable in packaging, and can withstand heavy weight and external impact. Our Anti-Rust Paper complies with many international environmental regulations, is phosphorus-free, heavy metal-free, green and environmentally friendly, and is safer to use.

FAQ of Anti-Rust Paper:

Q: What is the biggest difference between VCI Kraft Packaging Paper and ordinary VCI anti-rust paper?

A: VCI Kraft Packaging Paper can effectively prevent paper scraps and paper fluff from contaminating metal surfaces, and is particularly suitable for product packaging with high requirements for cleanliness.

Q: What materials are suitable for packaging with VCI Kraft Packaging Paper?

A: Corrosion Inhibiting Paper is suitable for metal materials with high cleanliness requirements such as ordinary cold plate, galvanized plate, tin plate, chrome plate, oriented silicon steel, non-oriented silicon steel, etc., and can also be used for the protection of the inner core of steel coils.

Q: What should be paid attention to when using Corrosion Inhibiting Paper?

A: The metal surface must be clean and dry; avoid direct contact between metal and anti-rust paper with bare hands during use; ensure that the Corrosion Inhibiting Paper surface faces the metal when packaging; the overlapping parts must be sealed intact.

About us:

CVCI has established 11 branches and subsidiaries across the country, built five major production bases and three R&D centers in Shenyang, Ningbo, Shanghai, Guangzhou and Chengdu, and formed a nationwide R&D-production-sales system to provide domestic and foreign customers with professional services such as anti-rust protection system design and full-process solution.