- Home

- >

- Products

- >

- VCI Stretch Film

- >

VCI Stretch Film

1. VCI stretch film has the characteristics of high tensile strength, high impact toughness, self-adhesive, transparent and light weight.

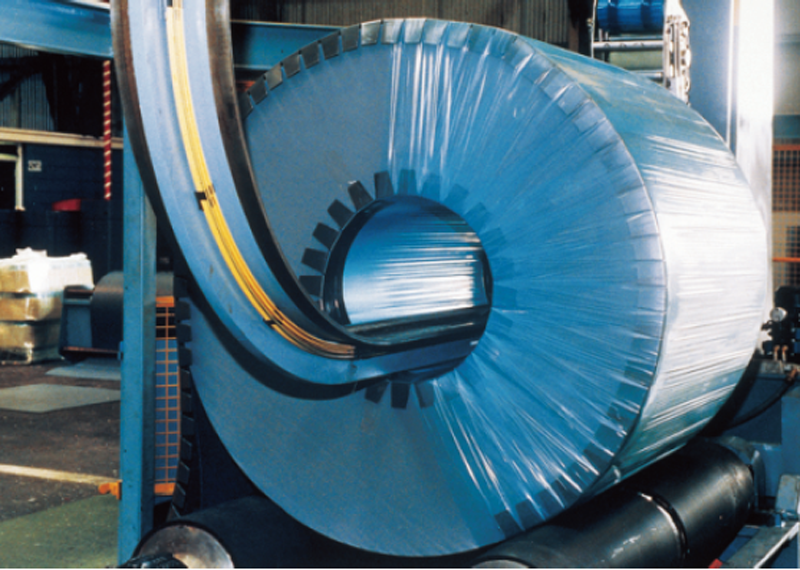

2. VCI stretch film is applicable to products with tight packaging and rustproof packaging, such as steel coils, steel strips, circular and circular parts, long rods and long strip metal products.

- CVCI

- China

- 14 days after payment

- 1500 tons per month

- Information

Product Introduction of VCI film anti rust:

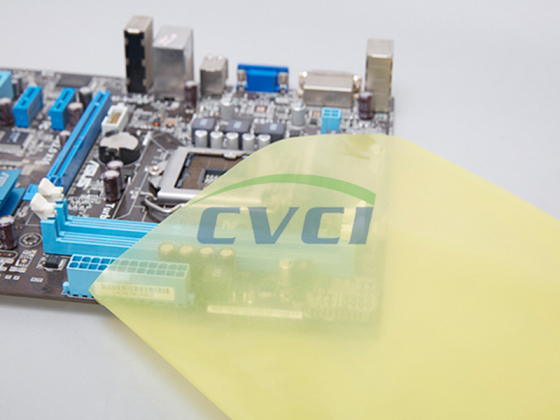

Our vci plastic anti rust film has the characteristics of high tensile strength, high impact toughness, self-adhesiveness, transparency and light weight, and is suitable for various fastening anti-rust packaging applications. VCI film anti rust is widely used in the packaging and storage and transportation protection of steel coils, steel strips, ring parts, ring parts, long rods or strips of metal products. We also provide VCI Stretch Film anti rust designed specifically for wrapping packaging, which is suitable for automatic or manual wrapping equipment. It can achieve anti-rust protection while ensuring physical fastening. It is one of the VCI film anti rust packaging solutions commonly used in steel, machinery, hardware and other industries.

Product model of VCI film anti rust: SF/DF.JC

Product form of anti rust film:

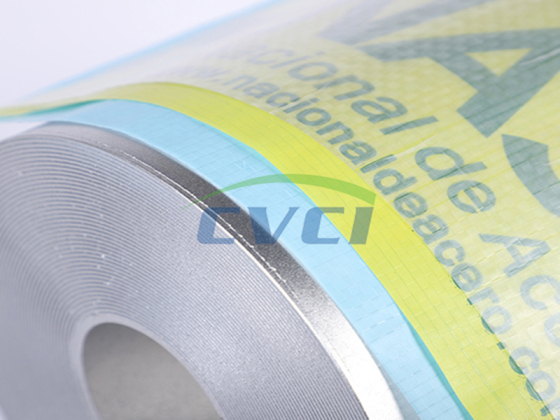

VCI plastic anti rust film is mainly provided in roll form in actual application, which is suitable for wrapping packaging. It can quickly and efficiently wrap metal products and release anti-rust gas simultaneously. The product is mainly blue, with eye-catching color, which is easy to identify and classify. Through wrapping, VCI Stretch Film anti rust not only has good fastening performance, but also can achieve continuous anti-rust protection during the packaging process. It is an ideal choice for automated packaging lines and manual packaging. As a high-performance VCI film anti rust material, it is widely used in industries such as steel and mechanical parts.

Performance characteristics of anti rust film:

VCI plastic anti rust film is made of VCI master batch and LDPE resin for extrusion and blow molding. VCI has good antirust function for ferrous metals, copper, aluminum and other metals. VCI plastic anti rust film has high tensile and impact toughness, self-adhesive, transparent, light weight and other characteristics.

Scope of application of anti rust film:

VCI Stretch Film anti rust is used for rust protection of steel, copper and copper alloy, aluminum and aluminum alloy, galvanized sheet, color coated sheet, tinplate, silicon steel and other materials. VCI Stretch Film anti rust is applicable to products with tight packaging and rust-proof packaging, such as steel coils, steel strips, circular and circular parts, long rods and long strip metal products.

Usage method of anti rust film:

After the metal products are cleaned and dried or oiled and dried, they are wrapped manually or automatically by machine to avoid water vapor intrusion.

FAQs:

Q: What is vci plastic anti rust film?

A: VCI plastic anti rust film is a stretch wrap film that also provides rust prevention.

Q: What is the difference between vci plastic anti rust film and ordinary stretch film?

A: Ordinary stretch film only provides fixation and dust protection, while VCI film anti rust offers additional rust prevention, making it ideal for transporting and storing metal products.

Q: What applications are suitable for VCI film anti rust?

A: VCI Stretch Film anti rust is commonly used for wrapping exterior packaging for products such as steel, copper, aluminum, automotive parts, and machinery, and is particularly suitable for long-term storage and export.

Q: How long does VCI Stretch Film anti rust's rust prevention last?

A: When used correctly and properly sealed, anti rust film provides effective rust protection for 6–18 months, depending on ambient humidity and the metal material.

About us:

CVCI has a technical team composed of chemical engineers and material experts, and continues to invest in the research and development of new VCI formulas and antistatic composite materials. Through independent formula control and advanced production technology, our VCI film anti rust has stable performance and long protection period, which can meet the high requirements of rust prevention of various complex metal materials.