VCI Powder For Ferrous Metals

1. VCI Powder For Metal uses a highly effective Corrosion Inhibitor formula. As a VCI Emitter anti rust powder with superior performance, it can quickly release vapor phase anti-rust molecules in a confined space and accurately cover the surface of various ferrous metals.

2. VCI powder For Metal products have passed international authoritative certifications such as REACH, ROHS, and SGS, and are VCI Emitter solutions that meet global environmental regulations.

3. VCI Powder For Metals can be flexibly used in a variety of enclosed spaces such as large equipment, cavities, and pipelines. As a long-lasting and effective anti rust powder and VCI Emitter Corrosion Inhibitor, it is widely adapted to different metal packaging needs.

- CVCI

- China

- 14 days after payment

- 1500 tons per month

- Information

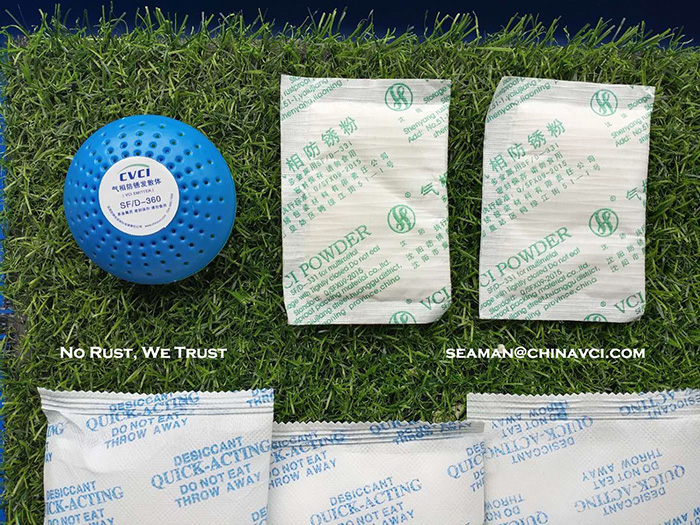

Product introduction of VCI Emitter:

Our VCI Powder For Metal is a highly effective anti rust powder designed for ferrous metals, suitable for long-term corrosion protection in large cavities and confined spaces. As a powerful VCI Emitter, this product releases gaseous VCI Emitter Corrosion Inhibitor through self-atomization, effectively covering the metal surface and preventing rust. Compared with conventional VCI powder, our formula incorporates flash rust inhibition ingredients, which has a faster onset and longer-lasting protective effect. It is widely used in equipment sealing, export packaging and precision parts storage scenarios. With finer particle size, more uniform distribution and convenient use, it is a trustworthy VCI anti rust powder solution.

Product Description of VCI powder:

VCI Powder For Metal has an extremely fast diffusion speed. Even in hard-to-reach spaces such as structural gaps, inside pipes and complex cavities, it can quickly release gaseous VCI Emitter Corrosion Inhibitor to effectively form a protective layer to prevent metal corrosion. At the same time, the VCI powder has excellent surface passivation ability and can effectively resist the erosion of external corrosion factors such as chlorides and acidic pollutants. As a high-performance anti rust powder, its formula is completely soluble in water and is suitable for a variety of applications such as wet laying, which improves the flexibility of use. The product has been tested to meet the MIL-PRF-22110 military standard and is superior to the commercial product requirements for material type 3 in CID AA-59441/5 in terms of physical properties. In addition, VCI Emitter is stable and non-flammable. VCI Emitter anti rust powder complies with the global automotive industry's material reporting requirements and many international environmental regulations such as TSCA, ECHA SVHC, RoHS and REACH. It is a trustworthy VCI Powder For Metal solution.

Features of VCI Powder For Metal:

VCI Powder For Metal quickly releases gas phase VCI Emitter Corrosion Inhibitor through VCI Emitter, which can quickly form a protective layer even in closed areas such as structural gaps, pipes and cavities.

Flash rust inhibition ingredients are added to the VCI powder formula to effectively prevent rapid corrosion of metals when they first come into contact with moisture.

As a safe and reliable anti rust powder, its use process will not cause metal hydrogen embrittlement and is suitable for applications with high safety requirements such as high-strength steel.

VCI Powder For Metal has excellent chemical corrosion resistance and can resist harmful media such as chlorides, acidic gases and salt spray in industrial environments.

VCI Emitter anti rust powder Corrosion Inhibitor can provide continuous protection for up to two years in a closed environment, making it an ideal choice for long-term storage and transportation of metal products.

Applications of anti rust powder:

VCI Powder For Ferrous Metals can be used as an efficient VCI Emitter for rust prevention in the inner cavity of pressure vessels, heat exchangers, boilers, pipelines and other equipment. It quickly covers the hard-to-reach metal surface by releasing VCI gas to form a durable VCI Emitter Corrosion Inhibitor protective layer.

Suitable for the protection of engineering machinery, mining equipment, military equipment, etc. before transportation or long-term decommissioning. VCI powder can effectively prevent flash rust and environmental corrosion to ensure the delivery of equipment in good condition.

During export or long-term storage, VCI Emitter anti rust powder Corrosion Inhibitor is used together with anti-rust packaging materials to protect cast iron, carbon steel and other parts from moisture and acidic pollutants.

Suitable for internal corrosion protection during maintenance or delivery of power equipment such as steam turbines and generators. VCI Powder For Metal can be safely used in scenes with high cleanliness requirements.

VCI Powder is used as a VCI Emitter in containers to prevent the erosion of salt spray and corrosive gases in sea transportation or high humidity environments to ensure that metal equipment arrives rust-free.

It is especially suitable for coastal warehousing, shipbuilding, heavy industry and other fields, providing long-term and reliable VCI anti rust powder Corrosion Inhibitor solutions for easily corrosive ferrous metals.

Notes of anti rust powder:

When using VCI Powder For Ferrous Metals, ensure that the metal surface is clean and dry, and evenly distribute the VCI powder in a confined space. The recommended dosage is 40-60 grams per cubic meter. It is recommended to set a release point every 1 to 1.5 meters inside the long cavity. As a VCI Emitter, the product releases VCI Emitter Corrosion Inhibitor in a sealed environment to form a protective layer, so it is necessary to ensure that the space is well sealed. If necessary, a desiccant can be used to enhance the protective effect. Close the space as soon as possible after distribution and keep it sealed for at least 12 hours to ensure that the VCI Emitter anti rust powder Corrosion Inhibitor fully exerts its anti-rust properties. Unused VCI Powder For Metal should be stored in a dry and cool place to prevent moisture from affecting the effect.

About us:

CVCI has established a nationwide R&D-production-sales system with its 11 branches, five production bases in Shenyang, Ningbo, Shanghai, Guangzhou and Chengdu, and three R&D centers. The company not only focuses on the development and manufacturing of high-performance anti-rust products such as VCI Powder For Ferrous Metals, but also provides professional anti-rust protection system design and full-process solutions for domestic and foreign customers. With advanced technical strength and a complete service system, CVCI is committed to providing efficient and long-lasting vapor phase anti-rust protection for various ferrous metal equipment.