- Home

- >

- Products

- >

- VCI Desiccant

- >

VCI Desiccant

1. Anti rust powder VCI Desiccant has excellent anti-rust performance + strong hygroscopic activity, quickly releasing corrosion inhibitor molecules while reducing the relative humidity in the package.

2. Anti rust powder VCI Desiccant's packaging adopts a double-layer packaging design of DuPont paper and high-grade non-woven fabric.

3. Volatile corrosion inhibitor's material composition is controllable, non-toxic and harmless, meeting the requirements of ROHS and REACH regulations and is green and environmentally friendly.

- CVCI

- China

- 14 days after payment

- 1500 tons per month

- Information

Product introduction of Volatile corrosion inhibitor:

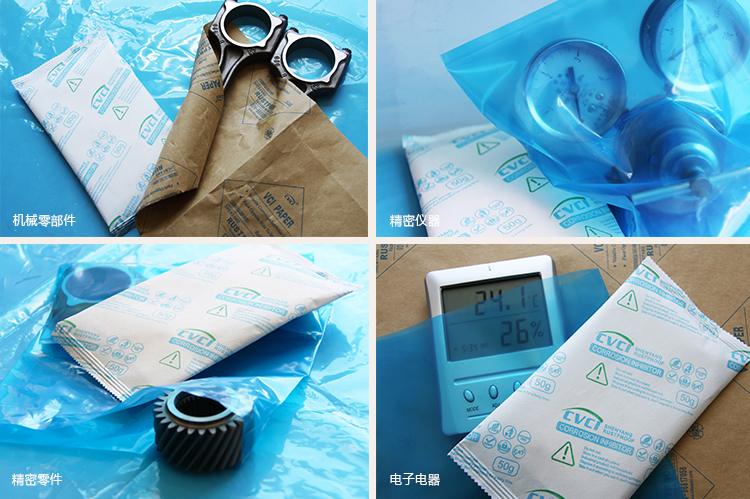

Volatile corrosion inhibitor produced by CVCI is made of high-efficiency vapor phase corrosion inhibitor and a variety of high-efficiency active adsorbents as raw materials. It is a scientifically formulated product that organically combines vapor phase rust prevention and dry packaging. It has excellent gasification and high-efficiency adsorption performance. Corrosion Inhibitor VCI Additive can be used for dry moisture-proof and rust-proof treatment of products in industries such as electronics, metal products, precision machinery, communications, military industry, building materials, and instruments.

Product advantages of Corrosion Inhibitor VCI Additive:

The Corrosion Inhibitor VCI Additive we produce has good anti-rust effect and strong moisture absorption capacity. It can release anti-rust ingredients while absorbing moisture, effectively protecting metal from rust. The packaging of anti rust powder VCI Desiccant adopts a sturdy double-layer structure of DuPont paper and non-woven fabric, which is not easy to break and is safer to use. Corrosion Inhibitor VCI Additive ingredients are safe, do not contain harmful substances, meet environmental protection requirements, and are suitable for export or precision products with environmental protection requirements.

Product application:

Electronic industry: Anti rust powder VCI Desiccant can be used for moisture-proof and rust-proof protection of circuit boards, chips, connectors and other products to prevent moisture and oxidation.

Metal products industry: Volatile corrosion inhibitor is suitable for packaging and rust-proofing of metal parts such as screws, knives, and hardware.

Precision machinery industry: used for long-term protection of high-precision parts such as precision bearings, gears, and molds.

Communication industry: suitable for anti-corrosion treatment of metal components and connectors inside communication equipment.

Building materials industry: can be used for moisture-proof and rust-proofing of steel, profiles, metal doors and windows and other building materials during transportation and storage.

Product specifications and technical indicators:

| Project | Content |

| Specification | 5g/bag, 10g/bag, 20g/bag, 25g/bag, 50g/bag |

| Appearance | Flexible packaging bag |

| Maximum moisture absorption rate (RH≥95%) | ≥200% |

| Gas phase corrosion inhibition test | Level 0, Level 1 |

Why must Volatile corrosion inhibitor be used?

If anti rust powder VCI Desiccant is not used during storage or transportation, metal products are prone to oxidation and rust due to moisture, water vapor intrusion or temperature changes, resulting in surface discoloration, spotting and corrosion, which in severe cases will affect the matching accuracy and performance of parts. Especially precision machinery, electronic products, hardware parts, etc. are extremely sensitive to humidity. Rusting not only affects the appearance, but may also cause functional failure or scrapping, increase rework and loss costs, and even affect customers' trust in product quality. Using Volatile corrosion inhibitor is a simple, economical but very effective way of protection.

About us:

As a technology pioneer in the industry, CVCI continues to promote product innovation, such as anti-static VCI film, transparent visual anti-rust film, multi-metal general VCI powder and other new products, which solve the problem that traditional packaging materials are difficult to balance rust prevention and electronic protection.