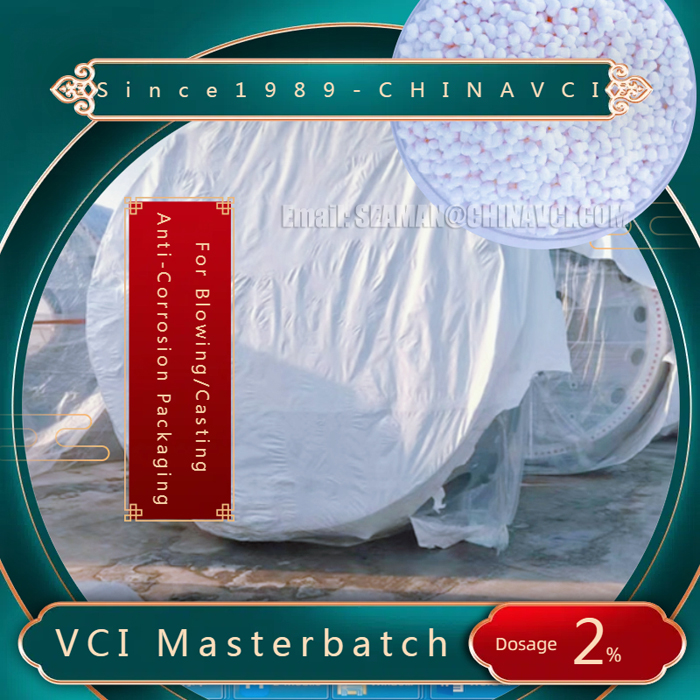

CHINA VCI Anti-Corrosion Masterbatch

Minimize Cost & Increase Performance

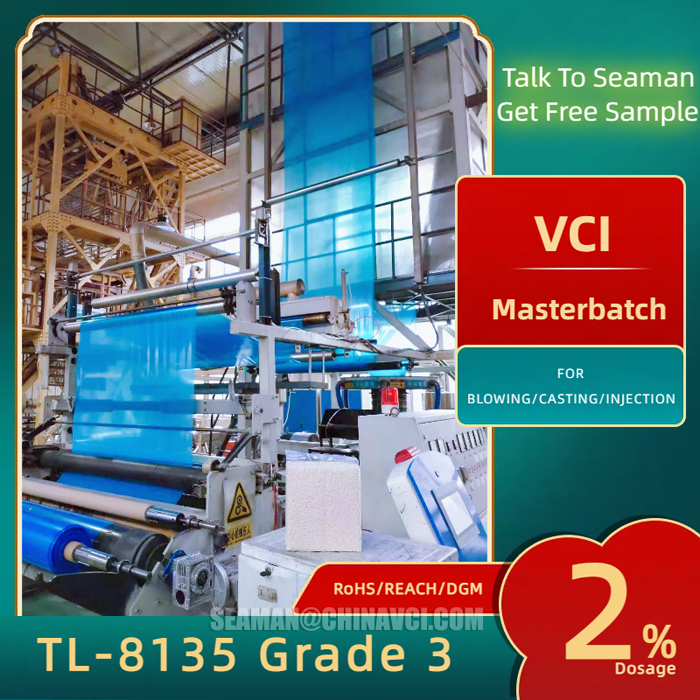

2% Dosage for Any Thickness VCI Film

Germany Local Test TL-8135 Grade 3

35 Years Factory Volkswagen Qualified Supplier

Works for All Metals

Suitable for All Blowing/Casting/Thermoforming/Injection

Reach & ROHS Compliant

DGM Safety Report for Air Transport

Talk To Mr. Seaman, Get Best Price:

WeChat/WhatsApp: +86 13704052430 Email:seaman@chinavci.com

Product description:

As VCI antirust masterbatch for multimetal, DM-130N is a kind of polyolefin resin,

VCI corrosion inhibitor and other additives mixed and produced by extrusion

Light yellow antirust plastic masterbatch, mainly used for VCI antirust plastic film manufacturing.

Product features:

1. The dosage of masterbatch is only 2%. It’s suitable for variety of metal antirust packaging.

2. The extrusion blow molding process is simple to operate, and regular extrusion equipment can be used to produce VCI films and bags.

3. In the process of producing VCI antirust plastic film products, functional master batches such as color masterbatch, antioxidant, flame retardant, etc. can be added as required.

Applicable metals:

Iron, cast iron, copper and copper alloy, aluminum and aluminum alloy, stainless steel, aluminum alloy and other metals.

Application:

It is suitable for the extrusion blow molding of VCI rustproof plastic film products, VCI rustproof heat-shrinkable films, VCI Bubble Bag, VCI trays, VCI Pod, and VCI rust-proof pearl cotton, ...etc. The application of other rust-proof plastic products needs to be determined through technical confirmation.

Processing methods and precautions:

a. Base material resin: Please use blown film grade low density polyethylene resin, medium density polyethylene resin, linear low density degree polyethylene resin.

b. Recommended dosage: 2% of rust-proof layer (can be appropriately increased or decreased according to customer's requirements for rustproof performance).

c. Manufacturing temperature: The temperature of extrusion blow molding is lower than 165-185 ° C.

d. When producing antirust film, the surrounding environment of work should be kept dry and ventilated. If the rustproof masterbatch is found to be damp, it should be dried. The treatment condition is to dry at 50 ° C for 90min.

e. The remaining rust-proof masterbatch processed should be re-moisturized and packed for later use.

Packing:

20kg per drum

540kg per pallet: 1.1m*1.1m*1.62m

Talk to Mr. Seaman, Get Best Price!

WeChat/WhatsApp: +86 13704052430 Email:seaman@chinavci.com

Storage:

1. The product should be stored in a cool, dry place, avoid direct sunlight and avoid contact with fire sources and polluting substances.

2. Sealed storage, shelf life is 12 months.