What Type of VCI Anti Rust Fluid Should Be Used for Aerospace-Grade Parts?

2026-01-05 09:58High-strength bolts, nuts, washers, and pins used in aerospace manufacturing, maintenance, and supply chains, if corroded, can lead to scrapping and rework in minor cases, and directly affect structural safety in severe cases. So, which rust preventative liquid should be used for aerospace-grade fasteners during long-term storage, international transportation, and in humid environments? As a professional manufacturer of rust prevention products, CVCI can help you choose the right VCI antirust fluid based on our many years of export experience.

Why are aerospace-grade fasteners prone to problems?

From a material perspective, aerospace fasteners are almost all made of high-strength alloy steel, stainless steel, and titanium alloys with complex heat treatment processes, extremely high surface precision requirements, small dimensional tolerances, and high assembly matching accuracy. These characteristics lead to a practical problem: once they rust, there is almost no way to repair them. Ordinary industrial fasteners might only have a little surface rust, which can be cleaned and reused; however, even pitting corrosion that is difficult to detect with the naked eye can lead to aerospace fasteners being scrapped. Even more troublesome, corrosion doesn't only occur during the use phase, but also extensively during: long-term storage, sea/air transportation, and storage and unpacking in tropical or coastal countries. Especially when exporting to high-temperature and high-humidity regions such as Southeast Asia and the Middle East, rust prevention problems become very serious.

Reasons why traditional rust prevention methods are unsuitable

Many companies initially used several rust prevention methods: applying rust-preventive oil, sealing after oil immersion, applying wax, and finally applying oil + desiccant. These methods were effective in the past, but in the context of aerospace fasteners, problems have gradually emerged: rust-preventive oil residue affects assembly, and aerospace assembly often requires clean surfaces, meaning the oil film needs secondary cleaning, increasing processes and costs; incomplete coverage means that dead corners will still rust; it's difficult to achieve 100% protection of thread roots, holes, and contact surfaces; it fails quickly in high-humidity and high-salt environments; in the rainy season in Southeast Asia and under sea transportation conditions, the protection period of traditional rust-preventive oil is significantly insufficient; and there are significant environmental and export compliance pressures, with some oil-based rust prevention products facing restrictions in terms of environmental protection, MSDS, and REACH.

Most metal rust prevention products use a more suitable rust prevention product – VCI antirust fluid.

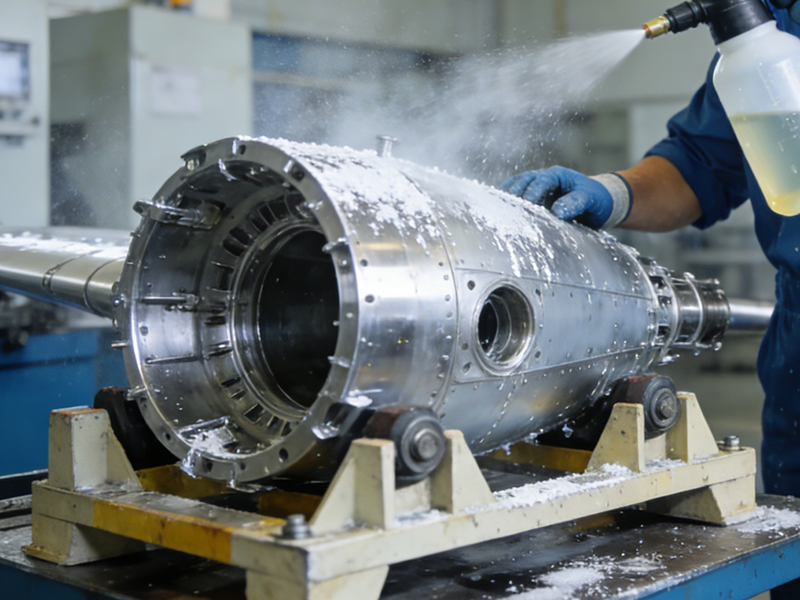

How does VCI antirust fluid work? Visible changes after using VCI antirust fluid: the fastener surface is dry and free of oil film; it does not affect subsequent assembly and torque; it provides overall protection even without complete contact; after packaging, the anti-rust effect lasts for months or even years. These points are crucial for aerospace-grade fasteners. The active ingredients in VCI antirust fluid slowly volatilize, forming gaseous molecules. These gaseous molecules automatically adsorb onto the metal surface, including: the outer surface, thread gaps, and tiny pores. VCI molecules form a molecular-level protective layer in a sealed environment. This invisible protective film inhibits corrosion from the source.

Reasons why VCI antirust fluid is particularly suitable for long-term storage and export

The advantages of VCI antirust fluid are very obvious: suitable for long-term storage (6 months / 12 months / longer); non-contact rust prevention allows for effective rust prevention of complex parts and structures; better results when used in combination with VCI anti-rust bags, anti-rust paper, and anti-rust film; especially when exporting to Southeast Asian countries, where high temperature, high humidity, and long shipping times are common, the stability advantages of VCI anti-rust are fully amplified.

Advantages of our VCI antirust fluid

Our VCI antirust fluid has a formula optimized for high-strength steel, stainless steel, and alloy materials; stable volatilization rate, suitable for long-term storage; free of heavy metals, meeting export environmental requirements; can be used for dipping, spraying, atomization, and inside sealed containers; compatible with a variety of packaging materials. Currently, our VCI anti-rust products have been exported to multiple countries and regions, with the highest proportion in the Southeast Asian market, widely used in fasteners, mechanical parts, and precision metal parts, covering warehousing, transportation, and long-term storage of spare parts. Many customers have given direct feedback that the products are ready to use upon unpacking, without the need for further cleaning, which is very convenient.

Some frequently asked questions from customers

Q: Will VCI antirust fluid affect aerospace certification?

A: VCI itself does not participate in the material structure and does not change the metal properties. The key lies in selection and verification.

Q: Can I only use VCI antirust fluid without anti-rust bags?

A: Yes, but combined use provides more stable results, especially for long-term export.

Q: What packaging methods are suitable for VCI antirust fluid?

A: The packaging solutions can be flexibly designed for boxes, pallets, and inside containers.

Compared to traditional rust prevention methods, VCI antirust fluid provides a more systematic solution, better suited for long-term storage and international logistics. What we are doing is making this solution more stable, more adaptable, and more suitable for export markets, especially for high-humidity environments such as Southeast Asia. If you also have a need for long-term rust prevention for your exported parts, please feel free to contact us via cvci-gaoxiu@chinavci.com or visit our factory to see how our rust prevention products undergo multiple rounds of testing before being delivered as qualified products to our customers.