Export Molds Are Protected Using VCI AntiRust Film

2026-01-07 10:26Whether it's injection molds, die-casting molds, stamping molds, or precision parts molds, as long as it involves international transportation, long-term storage, and high-humidity environments, rust prevention is a fundamental requirement for protecting the product. How should export molds be protected against rust?

Why is rust prevention necessary for exports?

Many mold companies have had similar experiences: the molds pass inspection domestically and appear to be in good condition before export, but upon unpacking at the customer's site, rust spots, pitting, and surface damage are discovered. The problem is often not the mold quality itself, but the risk of corrosion during transportation and storage. Once a mold rusts, it not only affects the appearance but may also directly affect the molding quality, and in severe cases, may even require return to the factory for repair. The export environment is harsher than imagined. Export molds face environments including: long sea shipping cycles (30-60 days or even longer), large day-night temperature differences in containers, easy condensation, long-term high temperature and high humidity in regions such as Southeast Asia, and the customer's warehouse may not be a temperature- and humidity-controlled environment. In this environment, if rust prevention measures are inadequate, the molds are almost unusable after rusting.

Problems with traditional mold rust prevention methods

Common methods for mold rust prevention include: thick application of rust-preventive oil, wax sealing, desiccant + plastic film, and simple oiling followed by wooden box packaging. These methods are not entirely useless, but they have encountered increasing problems during the export process. The rust-preventive oil used in the past is troublesome. If the oil is too thick, the customer must clean it before opening the mold, and incomplete cleaning affects trial molding. After the oil film ages, it can even absorb moisture. The rust prevention period is unstable, and if there is long-term sea shipping or a rainy season, the high risk remains. VCI AntiRust Film has become a crucial step in the rust prevention process for export by sea.

Changes in protection after using VCI rust-proof film

After using VCI AntiRust Film, the mold surface is dry upon unpacking, and it can be used immediately after removing the film without cleaning. Even after long-term storage, it is not prone to rusting. Using VCI rust-proof film provides comprehensive rust protection (outer surface + internal space), protecting complex structures without direct contact, suitable for long-term storage and export transportation, and does not affect mold accuracy or subsequent use. For export molds, this low-maintenance, high-stability rust prevention method is very attractive. How to Use VCI Anti-Rust Film

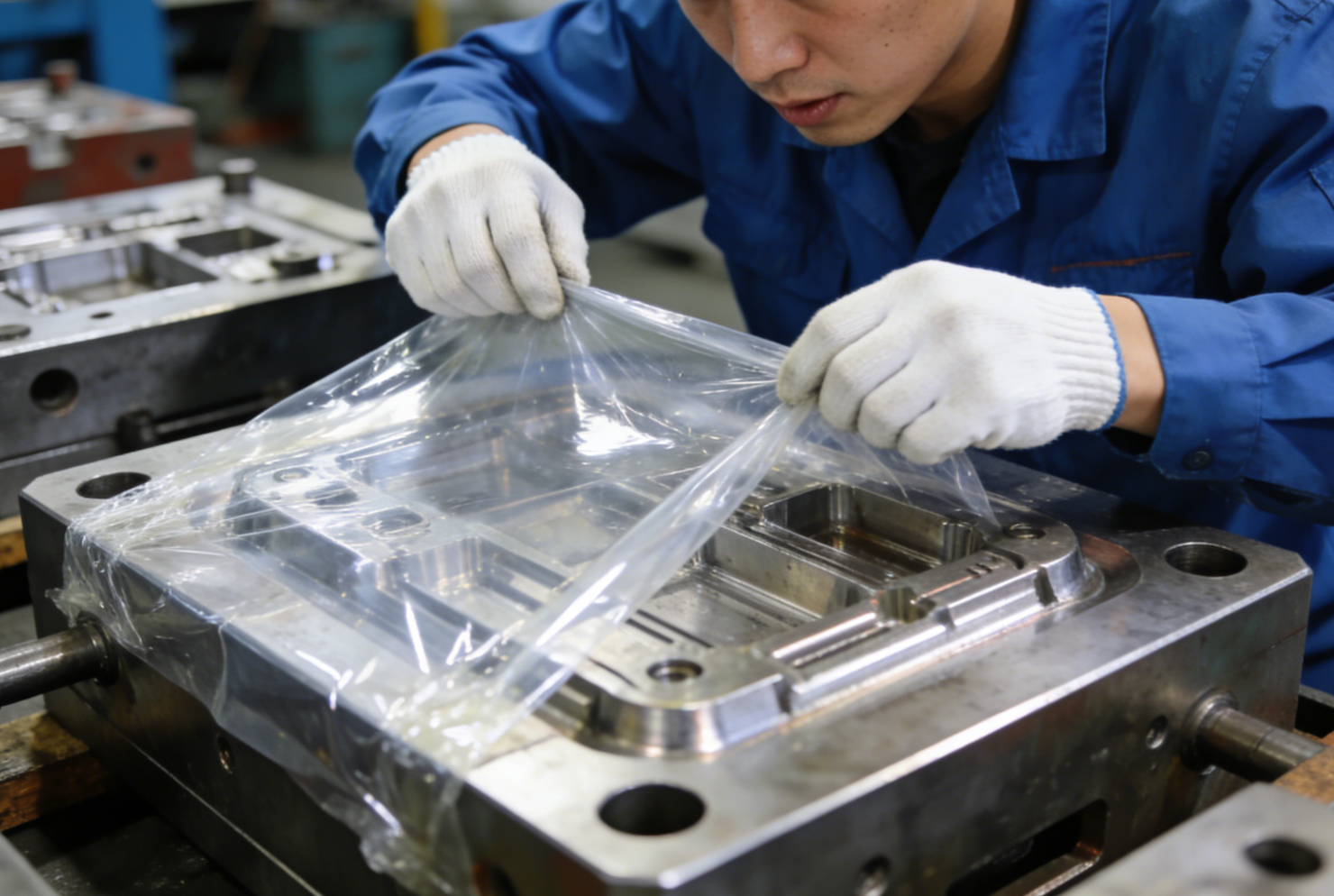

As a professional manufacturer of anti-rust products, we recommend the following method for using VCI antirust film during the export of molds: Clean and dry the mold, apply a small amount of auxiliary anti-rust measures to critical parts (such as anti-rust paper), wrap the entire mold with VCI antirust film, ensuring a tight seal to minimize air exchange, and then place it in a wooden box or container. For extra-large molds, a combination of partial wrapping and overall environmental protection can also be used.

Features of Our VCI AntiRust Film

As a company focused on anti-rust materials, CVCI emphasizes practicality and suitability for export in the research and development and application of VCI antirust film. The main features of CVCI's VCI antirust film include: suitable for common mold materials such as mold steel, carbon steel, and alloy steel; stable anti-rust period, suitable for long-term export transportation; high film strength, not easily damaged; free of heavy metals, meeting export environmental requirements; and customizable in size and thickness according to customer needs. Currently, our VCI antirust film products have been exported to many countries and regions, with a high proportion in the Southeast Asian market. They are widely used in injection molds, die-casting molds, and mechanical molds, and are suitable for high-temperature and high-humidity environments. Many customers have reported that using VCI antirust film significantly reduces the risk of mold damage upon arrival at the customer's site.

Choosing the right anti-rust method for exported molds can save a lot of unseen costs. In the field of mold export, the question is not whether to use anti-rust measures, but rather which method is the most reliable. Compared with traditional anti-rust methods, VCI antirust film provides a systematic solution that is more suitable for complex structures, long-term transportation, and high-humidity environments such as Southeast Asia. What we are doing is making VCI antirust film more stable, easier to use, and more suitable for the export market.

If you need anti-rust protection for your exported molds, or have other metal products that need to be exported, please feel free to contact us via email. We can help you choose the most suitable anti-rust packaging solution for your products based on your equipment type, transportation method, and export market, solving your product rusting problems. If time permits, you are also welcome to visit our factory to see the production process and actual application cases of our anti-rust film. You will trust us even more!