Does VCI Antirust Film Have a Significant Impact on Metal Parts?

2026-01-09 10:58Manufacturing exports continue to grow, with mechanical parts, molds, equipment components, and even aerospace materials flowing across borders. However, rust during sea transport has become a very serious problem. This is especially true for routes across Southeast Asia and the equatorial region, where high humidity and salinity, coupled with condensation inside containers, frequently lead to metal parts arriving at their destination rusted, discolored, and requiring rework and secondary polishing. Many people ask: Does long-distance sea transport really make metal parts more susceptible to rust?

What factors in the sea transport process cause metal to rust?

1. Salt spray + humidity. The most typical element in the marine environment is salt spray. Sodium chloride diffuses in water vapor and adheres to the metal surface, greatly promoting electrochemical corrosion. Compared to ordinary humidity, the corrosion rate in salty, humid air is often several times higher. Data from Southeast Asian routes shows that cabin humidity is consistently between 70% and 95%, and some voyages even experience humidity exceeding 90% for a week straight, creating a breeding ground for chronic corrosion of steel and castings.

2. Condensation inside the container, known in the industry as "container rain," especially occurs when: the temperature upon loading is high, the temperature at sea is low, and the voyage is long. When the temperature difference is significant, water droplets drip from the top of the container onto the cargo. This water directly causes pitting corrosion, localized corrosion spots, and yellowing. Many mold exporters are surprised to find that the corrosion comes from condensation inside the container.

3. Oxygen stratification corrosion caused by the enclosed environment of the ship's hold. Although seemingly enclosed, the oxygen distribution is uneven, accelerating the rate of localized corrosion, especially in low-carbon steel parts.

4. Long-term transportation. The longer the transportation period, the more complete the corrosion reaction, and the more likely it is to cause permanent damage. Voyages to South America, Southeast Asia, and Europe typically last between 20 and 50 days, which is sufficient time for metal surfaces to yellow, rust, and even experience pitting corrosion.

Application of New Anti-Rust Products

Many factories previously used methods such as applying oil, grease, plastic wrapping, and cardboard boxes with desiccants. However, various problems arose after actual export: rust-preventive oil required cleaning upon arrival at the port, and environmental requirements were increasing; grease was stable during transportation but customers complained about the mess; desiccants were ineffective against salt spray; plastic wrapping did not prevent corrosion, only isolating the air; traditional oil paper leaked oil, had an oily smell, and failed in the presence of salt spray.

In particular, European/American/Japanese customers have explicitly requested the prohibition of grease-based protection, citing high cleaning costs, failure to meet environmental standards, and negative impact on subsequent material processing. Therefore, new solutions have emerged, the most typical being VCI antirust film, which has been widely discussed in recent years.

Actual Effects of VCI AntiRust Film in Sea Shipping

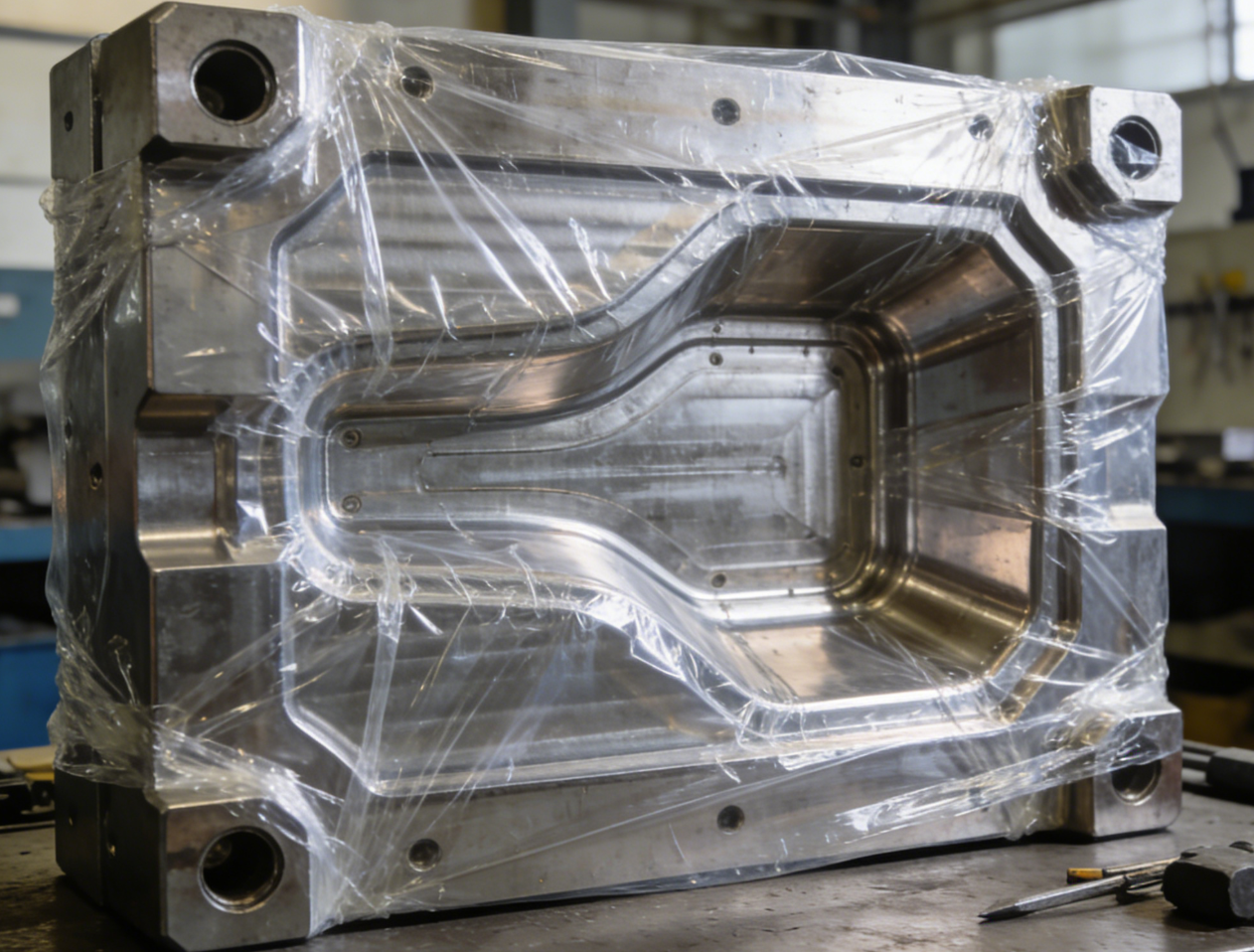

Export manufacturers generally report that the effect is significantly more stable than oil and desiccants, the packaging is clean and non-sticky upon opening, and customers save time on processing. Several advantages include: suitability for metals such as steel, iron, cast iron, and copper alloys; significant salt spray resistance; stable performance during long-term transportation; no cleaning required before subsequent processing; and compliance with the trend of oil-free protection. Our own customer cases, mainly exporting to Malaysia, Vietnam, Indonesia, the Philippines, and Thailand, are very representative. Previously, 60% of molds required rework upon arrival at the port; now, after using VCI film, less than 5% experience corrosion. Japanese customers have high processing requirements, and the products can be directly processed on machines after unpacking, greatly saving on cleaning. The difference is even more significant on routes exceeding 20 days.

Features of Our VCI AntiRust Film (Export Type)

Our export-type VCI antirust film has undergone repeated testing in our laboratory, supporting long-distance shipping (30-90 days), multi-metal compatibility, oil-free, odorless, non-sticky, customizable for tensile strength or thickness, and has passed RoHS and other environmental tests. We have continuous shipments to the Southeast Asian market. Our current export countries and regions are mainly in Southeast Asia: Malaysia, Vietnam, Indonesia, Thailand, and the Philippines, followed by the Middle East and some European customers. It is worth emphasizing that the high humidity and high salt environment of Southeast Asia is very suitable for VCI antirust film products, and customer satisfaction is very high.

If you're also struggling with rust prevention issues for metal parts during sea transportation, feel free to contact us anytime. We can help you choose the right rust prevention products and solutions based on your metal part type, size, storage period, and target market. If possible, we also welcome you to visit our factory to see our VCI antirust film production process and our rigorous testing procedures. You'll be confident in the effectiveness of our products.