- Home

- >

- Products

- >

- VCI Masterbatch

- >

VCI Masterbatch

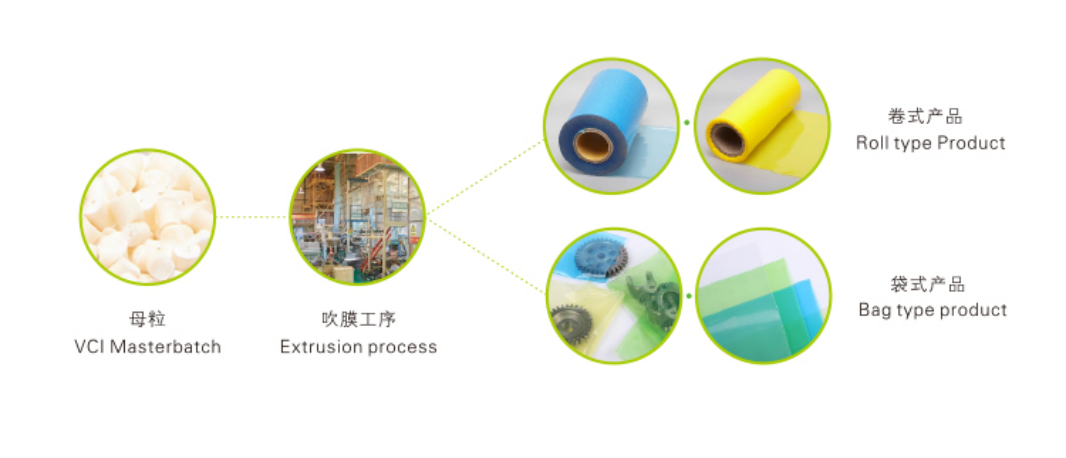

1. Concentrated Masterbatch for multi-metals is a yellowish antirust Concentrated masterbatch produced by extrusion of polyolefin resin, VCI and other additives, which is mainly used for the production and manufacture of VCI antirust plastic film products.

2. Concentrated Masterbatch is the concentrated version of 124 type Concentrated masterbatch, with very low addition ratio. It is a multi-metal antirust masterbatch with high cost performance.

- CVCI

- China

- 14 days after payment

- 1500 tons per month

- Information

- Video

- Download

Product introduction:

White VCI masterbatch for Multimetal DM-124 does not contain sodium nitrite, phosphate, chromate, or amines. It is a white or light yellow rust-proof plastic masterbatch made by mixing polyolefin resin, vapor phase corrosion inhibitor, and other additives through extrusion. Nitrite Free VCI Masterbatch is mainly used in the production of vapor phase rust-proof plastic film products.

Product model: SF/DM124

Product features:

1. White VCI MASTERBATCH does not contain sodium nitrite, phosphate, chromate, or amine.

2. White VCI masterbatch meets ROHS regulations.

3. Concentrated masterbatch is non-irritating to the skin and is safe and reliable.

4. The addition ratio of Nitrite Free VCI Masterbatch is low. It is suitable for a variety of metal anti-rust packaging.

5. In the production of gas phase anti-rust plastic film products, functional masterbatches such as antistatic agents, antioxidants, and flame retardants can be added as needed.

Applicable metal range:

White VCI masterbatch or supporting additives are widely used in the rust protection of various metals and their alloy products, especially suitable for the following metal categories:

Ordinary carbon steel and alloy steel.

Gray cast iron, ductile iron and other cast iron materials.

Copper and copper alloys such as brass and bronze.

Aluminum, pure aluminum and various aluminum alloys (such as ADC12, 6061, 7075, etc.)

Various stainless steel materials (such as 304, 316, 430, etc.)

Volatile Corrosion Inhibitor Masterbatch has excellent adaptability and can form an efficient anti-rust barrier layer on different metal surfaces. It can be used in various precision parts, mechanical structural parts, electronic housings, pipes, plates and other scenes to effectively prevent oxidation and corrosion.

Note:

When using White VCI masterbatch for Multimetal for blown film processing, it is recommended to use blown film grade LDPE, MDPE or LLDPE resin as the base material. The recommended addition ratio is 2.0% of the anti-rust film layer, which can be flexibly adjusted according to the actual anti-rust requirements. The processing temperature should be controlled below 185°C to protect the stable release of active ingredients. During the production process, the operating environment must be kept ventilated and dry. If Nitrite Free VCI Masterbatch is damp, it should be ventilated and dried at 50°C for 90 minutes. Please seal the unused Plastic VCI Masterbatch in time to prevent moisture absorption and affect the effect.

Packaging and Storage:

Concentrated masterbatch is packaged in durable cardboard barrels with a standard specification of 20 kg/barrel, and can also be customized according to customer needs. In order to ensure the stable function of the active ingredients of white VCI Masterbatch for Multimetal, it is recommended to store the product in a cool, dry, well-ventilated environment, away from direct sunlight, high temperature and humidity, and contact with fire, corrosive or polluting substances. Under sealed storage conditions, the effective storage period of Concentrated masterbatch is 12 months. Nitrite Free white VCI Masterbatch for Multimetal has the appearance of white particles, which is easy to identify and mix, and is an ideal additive for White VCI Masterbatch for Multimetal packaging materials.

Laboratory:

Our laboratory serves not only internal R&D but is also open to customers. Customers can send their products to the lab, where we conduct material matching and performance testing based on their specific needs. This collaborative model allows customers to witness the experimental process and results firsthand, fostering trust and ensuring solutions are more practical.

Long-term partnership:

The relationship between CVCI and its customers is not just about supply and demand, but about cooperation and mutual benefit. After using our rust prevention products, companies like Volkswagen, Tesla, and Changan have seen a significant reduction in transportation losses and a significant improvement in overall packaging efficiency. Our customers' success is our greatest achievement.

About us:

CVCI's range of corrosion protection products—including VCI paper, VCI film, white VCI Masterbatch for Multimetal, and VCI powder—has been successfully exported to over 40 countries and regions such as the U.S., Italy, Turkey, Japan, and Singapore. With a solid international presence, our brand has gained widespread trust and helped promote industrial advancement.