Concentrated VCI Masterbatch

1. Nitrite Free VCI masterbatch DM-130N is a white or light yellow antirust plastic masterbatch produced by extrusion of polyolefin resin, VCI and other additives.

2. VCI Master Batch is a Safe type Resin.

3. VCI Master Batch passed REACH, SGS, REACH.

- CVCI

- China

- 5 days after payment

- 500 tons per month

- Information

- Video

- Download

Product description of VCI Master Batch:

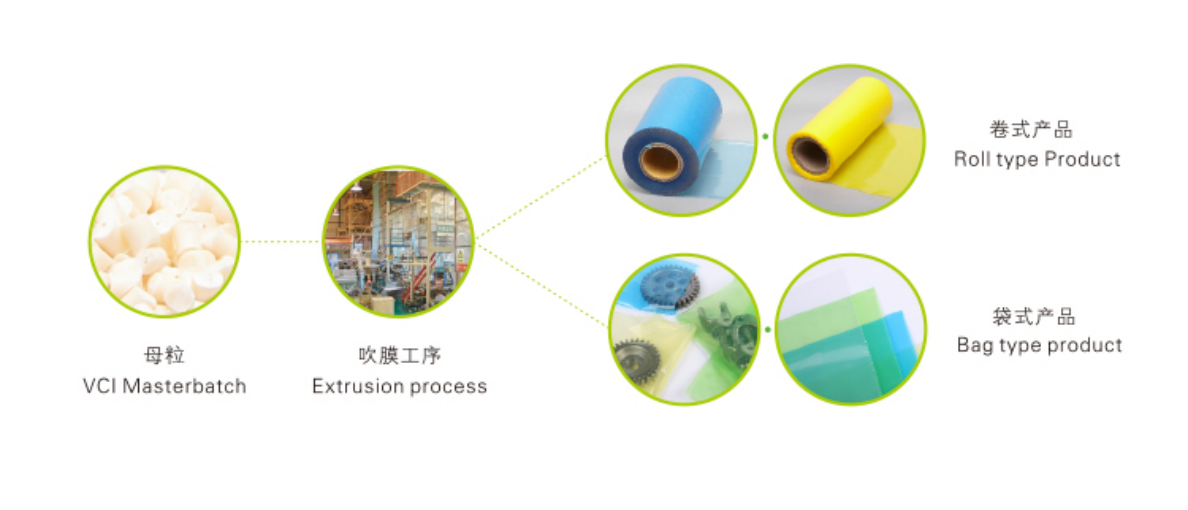

Nitrite Free VCI Masterbatch DM130N is a yellowish anti-rust plastic Corrosion Inhibitor VCI Master Batch made by mixing polyolefin resin, vapor phase corrosion inhibitor and other additives through extrusion. It is mainly used in the production of vapor phase anti-rust plastic film products. VCI Concentrate is a concentrated version of 130 VCI Master Batch with a very low addition ratio. It is a cost-effective multi-metal anti-rust VCI Concentrate.

Product model: SF/DM-130N

Product features of Corrosion Inhibitor:

1. Nitrite Free VCI Masterbatch addition ratio is low. Suitable for a variety of metal anti-rust packaging.

2. Nitrite Free VCI Masterbatch extrusion blow molding process is simple to operate and can be produced with ordinary film blowing equipment.

3. VCI Masterbatch can add color masterbatch, antioxidant, flame retardant and other functional masterbatch as needed during the production of gas phase anti-rust plastic film products.

VCI Master batch application range:

Corrosion Inhibitor VCI Concentrate is applicable to metals including iron, cast iron, copper and copper alloys, aluminum and aluminum alloys, stainless steel, aluminum alloys and other metals. Corrosion Inhibitor is applicable to the extrusion blow molding of vapor phase rust-proof plastic film products, vapor phase rust-proof heat shrinkable film and vapor phase rust-proof pearl cotton. The application of other anti-rust plastic products needs to be determined by the process.

Notes of VCI masterbatch:

1. Corrosion Inhibitor VCI Master Batch base resin: Please use blown film grade low-density polyethylene resin, medium-density polyethylene resin, linear low-density polyethylene resin.

2. Recommended Corrosion Inhibitor VCI Master Batch addition ratio: 2% of the anti-rust layer (can be increased or decreased according to customer anti-rust performance requirements).

3. VCI Concentrate blown film temperature: extrusion blow molding processing temperature is lower than 185℃.

4. When producing anti-rust film, the working environment should be kept ventilated and dry. If VCI Concentrate is found to be damp, it should be dried at 50℃ for 90 minutes.

5. The remaining VCI Masterbatch should be re-packed in moisture-proof packaging for standby use.

6. Packaging and storage: cardboard barrel packaging, 20 kg/barrel, or agreed packaging. VCI Concentrate should be stored in a cool and dry place, away from direct sunlight, fire sources and pollutants. Sealed storage, shelf life 12 months.

FAQs of VCI Concentrate:

Q: What is Corrosion Inhibitor VCI Concentrate?

A: VCI Master Batch is a functional masterbatch containing a high proportion of active rust-inhibiting ingredients. It is used for mixing with plastics for extrusion or blown film, imparting long-lasting rust-proof properties to packaging materials.

Q: Why choose a concentrated version VCI masterbatch over a standard version?

A: Concentrated VCI masterbatch requires a smaller addition ratio to achieve the same rust-proofing effect, saving costs while ensuring stable physical properties of the plastic product.

Q: What processing methods are suitable for Nitrite Free VCI Masterbatch?

A: VCI Concentrate can be used in a variety of plastic processing techniques, including blown film, injection molding, and cast film. It is particularly suitable for the production of VCI films, rust-proof bags, and rust-proof covers.

Q: What precautions should be taken when using VCI Master Batch?

A: It is recommended to mix directly with the base resin according to the recommended ratio without additional additives. Avoid prolonged exposure to high temperatures to maintain the activity of the rust-proof ingredients.

Q: What industries are VCI Master Batch primarily used in?

A: Nitrite Free VCI Masterbatch is widely used in rust-proof packaging for steel, automotive parts, machinery, electronic components, and other applications. It is particularly suitable for customers requiring long-term storage and ocean shipping.

Product and Company Certifications:

CVCI has received over 40 awards at the provincial and ministerial levels and above, covering technological innovation and product achievements. The majority of these awards are related to core products such as anti-rust paper, anti-rust oil, and Corrosion Inhibitor VCI Concentrate. These awards not only represent government and industry recognition of CVCI, but also demonstrate the outstanding effectiveness of our anti-rust solutions in practical applications, truly resolving customer challenges.

About us:

Founded in 1989, CVCI has been focusing on surface protection for 33 years. It is a national high-tech enterprise specializing in the research, development, manufacturing and application services of metal anti-rust protection materials, mainly vapor phase VCI Concentrate. We are the first in the industry to pass ISO9001 and ISO14001 system certification.