Which Industries Use Anti Rust Film?

2025-12-02 14:58Metal surfaces readily oxidize when exposed to moisture, oxygen, and even slight temperature changes. The presence of salt or acidic gases in the environment can double the corrosion rate. Therefore, whether in equipment manufacturing, parts processing, or international transportation, everyone faces the same challenge: how to keep metals "clean and rust-free" before storage, transportation, and use. Consequently, rust-preventive products have become standard equipment in many factories.

Why do metals rust easily?

Rusting is essentially a natural process of "restoration." Once extracted from ore, metals are inherently unstable and constantly attempt to revert to an oxidized state. When air humidity exceeds 60%, especially in the humid and hot environments of southern or coastal regions, chemical reactions readily occur on metal surfaces. Even storing parts in a warehouse can result in condensation due to temperature fluctuations, potentially leading to a thin layer of rust the next day. Therefore, manufacturing companies never dare to be complacent, especially in markets like Southeast Asia where humidity remains high year-round. Customers there are highly dependent on rust-preventive products, and the anti rust film rust-preventive films, rust-preventive bags, and rust-preventive powders we export to these regions are all products with very stable demand.

Why is anti rust film necessary?

Many companies initially think that a little rust on metal is insignificant, but they only realize the problem when it arises: it's not a small cost issue, but a major loss. For example, rust on machined parts may force rework; if engine parts develop rust spots during transport, the entire batch may need to be re-inspected; rust on molds directly affects product precision; and for some precision components, such as aerospace parts, medical devices, and semiconductor equipment, even a tiny, visible rust spot can render them unusable. The role of anti rust film is to establish an "invisible barrier" in advance, keeping metal stable during storage and transportation and avoiding various uncontrollable risks.

What are the different types of anti rust film rust-preventive films?

Anti rust film rust-preventive films come in many forms, including solutions using ordinary PE film in conjunction with rust-preventive oil, and VCI anti rust films with independent rust-preventive functions. Ordinary films don't prevent rust themselves; they only block environmental factors. However, their effectiveness diminishes significantly in high humidity or long transport distances. VCI anti rust film, on the other hand, is an "active rust inhibitor." It provides protection directly through packaging without the need for additional oiling or cleaning. Therefore, in recent years, when exporting to Southeast Asian markets, we've noticed a significant increase in customer preference for VCI anti rust film. Due to the humid climate and long transport distances, they require a stable, reliable, and non-invasive rust prevention method.

What is VCI anti rust film?

VCI anti rust film, also known as volatile rust inhibitor film, is a high-efficiency packaging material that protects metal by volatilizing trace amounts of rust-inhibiting agents. Its key feature is that the rust-inhibiting molecules can diffuse in a closed environment and automatically adhere to the metal surface, forming a nearly invisible protective film. This protective film does not affect the metal's appearance or dimensional accuracy, making it particularly suitable for industries such as machined parts, precision parts, exposed metal, motors, and automotive parts. Unlike rust-preventive oils, anti rust film doesn't require cleaning, saving manpower and time, and it doesn't pollute the environment. This is a major reason why we have been able to consistently export this type of product to countries like Vietnam, Malaysia, and the Philippines.

Benefits and Application Scenarios of VCI anti rust film

The biggest advantage of VCI anti rust film is its ease of use and convenience. It eliminates the need for oiling or applying rust inhibitors; after packaging, parts can be directly stored or shipped. No oil stains are left after unpacking, allowing parts to proceed directly to the next process. Furthermore, it is applicable to most common metals, including steel, iron, cast iron, copper, and aluminum, making its applications very broad, including:

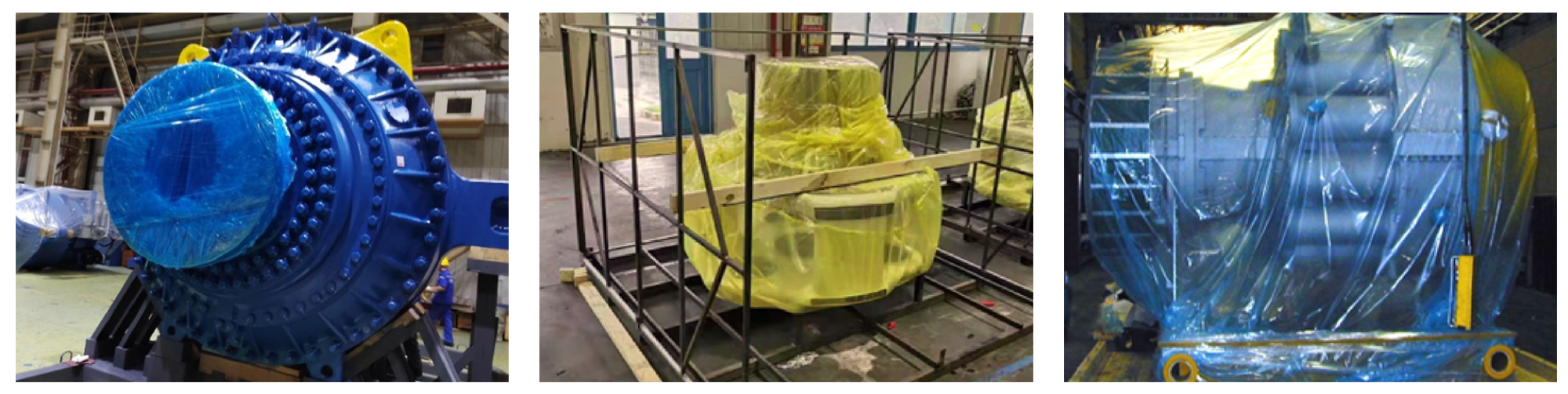

Machinery Manufacturing Industry: Gears, bearings, connecting rods, flanges, valve bodies, machined parts, etc.

Automotive Industry: Engine parts, stamped parts, chassis parts, precision electronic control metal parts.

Electronics and Electrical Industry: Power modules, hardware structural parts, coil cores, etc.

Aerospace Industry: Aluminum alloy structural parts, precision machined parts, high-value components.

Metallurgical Industry: Metal sheets, profiles, steel coils, copper, aluminum, etc.

Mold Industry: Injection molds, die-casting molds, stamping molds, etc.

International Export Industry: Where transportation times are long and environments are unstable, anti rust film is essentially standard equipment.

Especially in the export industry, customers are most afraid of discovering rust upon arrival at the destination port. VCI anti rust film effectively maintains a clean and stable internal space, making it ideal for long-distance transportation and sea freight environments.

Which industries typically use anti rust film in large quantities?

This is the core question of this article. Industries that truly use rust-preventive films extensively and frequently can be roughly divided into the following categories:

1. Machining and Manufacturing Enterprises: Machined parts will quickly develop oxidation spots if not properly protected within a few days. Therefore, factories usually use anti rust film bags for packaging directly after production, saving time and effort for warehouse management.

2. Automotive Parts Supply Chain: Automotive suppliers generally require stable, high-volume, and standardized rust prevention solutions. Therefore, VCI anti rust film is a widely used packaging material from factory warehouses to transport pallets and then to the OEM's incoming inspection.

3. Electrical, Electronic Control, and Electronic Industries: These products have precise structures and high cleanliness requirements. Copper and aluminum are also highly susceptible to corrosion. Therefore, buyers usually directly specify the use of VCI anti rust film and VCI rust-preventive bags.

4. Aerospace Industry: Aluminum and magnesium alloy parts are extremely sensitive to corrosion; even a slight corrosion can affect safety. Therefore, these companies consider VCI anti rust film a necessity.

5. Metal Material Import and Export Companies: Steel coils, aluminum coils, and copper materials frequently encounter humidity issues during container transport. Using VCI anti rust film in conjunction with desiccants is now an industry consensus.

6. Mold Industry: Even a small amount of rust on molds can affect production yield. Therefore, mold exporters almost universally use VCI anti rust film.

In short, any industry that relies on metals, humid environments, transportation risks, or long-term storage will generally use anti-rust films extensively and for extended periods.

Anti rust film, especially VCI anti rust film, has transformed from an "optional" to a "must-have" for many industries. It not only solves corrosion problems caused by humidity, oxidation, and condensation during sea transport, but also effectively reduces rework, labor costs, and product losses. Because of its ease of use, environmental friendliness, and wide applicability, our VCI series products have been consistently exported to Vietnam, Malaysia, the Philippines, and many other Southeast Asian countries, gradually becoming a staple product for local customers.

Rusting is a natural phenomenon, but rust prevention is not a problem. With the right methods and materials, the issue can be easily resolved.