What Are the Differences Between VCI Film and VCI Oil?

2025-12-05 14:31In manufacturing, metal rusting is truly commonplace. You might painstakingly machine parts to a shine, only to find them covered in red spots after a week in the warehouse; products exported to Southeast Asia might be found to be rusty upon unpacking, despite being in perfect condition at the time of manufacture, only to be damaged during sea transport. Therefore, many factories are increasingly focusing on rust prevention, and common rust prevention methods are VCI rust preventive oil and anti rust film. What are the differences between these two? How should you choose?

I. Why does metal rust so easily?

To understand the role of rust-preventive products, we must first understand how rusting occurs. The principle behind metal rusting is actually quite simple: oxygen and moisture in the air, combined with condensation caused by temperature changes, create the necessary conditions for the metal to slowly oxidize.

A common example: In northern winters, when a warehouse door is opened and closed, cold air meets warm, humid air, immediately causing a thin layer of condensation to form on the metal surface. Although this layer of water is almost imperceptible, it is enough to cause unprotected metal to begin oxidizing in a short time. For example, goods exported by sea are often stored in shipping containers where daytime temperatures are high and nighttime temperatures are low, leading to frequent condensation on the inner walls. Metal exposed to this environment can rust within just ten days.

In other words, rusting is not an accident, but an inevitability. As long as metal is exposed to air, it cannot maintain its unchanging shine indefinitely. Therefore, rust prevention is not superfluous for manufacturers, but rather a means to maintain a controllable condition for products during warehousing, transportation, and even long-term storage.

II. Why are rust-preventive products needed?

Many factories used to have a simple understanding of rust prevention: applying some machine oil or wrapping it in paper to prevent rusting was sufficient. However, modern metal parts, from automotive and aerospace to machining, have increasingly stringent surface requirements. Once rust appears, the probability of customer returns is very high. Furthermore, even slight corrosion of some precision parts can affect their functionality, which cannot be solved by simple polishing.

The core purpose of using professional rust-preventive products is to reduce losses, especially for export-oriented companies. Goods shipped from your factory may not reach the customer for up to 30 days, during which time they face multiple risks, including humidity along the way, port storage, and temperature fluctuations during sea transport. Without proper rust prevention, it's like gambling with your resources.

Furthermore, your products are exported to Southeast Asian countries like Vietnam, Malaysia, and the Philippines, where the average humidity is almost always above 80% year-round. In such environments, rust is the biggest problem. Therefore, companies engaged in international trade and manufacturing precision parts have realized that rust-preventive products are not an added value, but a basic requirement.

III. What is anti rust film? What are its benefits?

Many people encountering rust-preventive films for the first time are confused: "Can a plastic film really prevent rust?" Actually, anti rust film is not simple plastic; it contains volatile rust-preventive agents that continuously release rust-preventive molecules in a sealed environment. These VCI molecules automatically adhere to the metal surface, forming a protective film invisible to the naked eye.

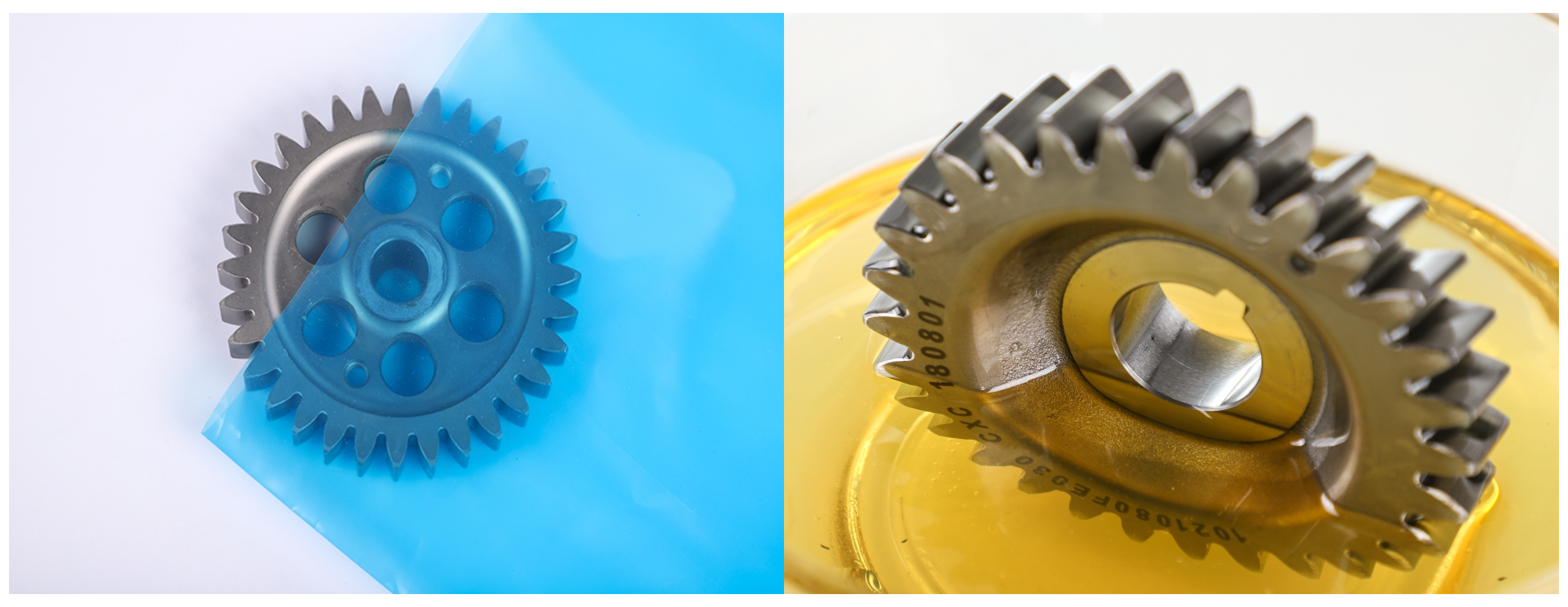

The biggest feature of anti rust film is its "oil-free" operation. You don't need to oil, clean, or degrease the parts; it's a completely clean and refreshing rust prevention method, especially suitable for factory workers who don't want greasy hands. Many electronic components, precision gears, motor parts, and hardware parts prefer anti rust film because it doesn't change the original state of the parts; customers can use it immediately after opening the bag.

Besides being clean, anti rust film has another advantage: it's extremely simple to use—just bag it, seal it, and you're done. Traditional rust-preventive oils require brushing, soaking, and drying, a lengthy and costly process, while anti rust film is as easy as using a packaging bag.

Moreover, adds almost no weight, which is crucial for export companies because ocean freight is calculated by weight and volume. Compared to the "weight of the oil drum" of rust-preventive oil, a thin sheet of film is incredibly light.

For this reason, many export companies, especially manufacturers exporting to Southeast Asia, are gradually shifting from traditional oil-based rust prevention to film-based rust prevention.

IV. What are the advantages of VCI rust preventive oil? What scenarios is it suitable for?

While anti rust film is convenient, VCI rust preventive oil remains an irreplaceable choice for many companies. Especially for complex metal parts with holes and gaps, VCI rust preventive oil's penetration is far superior to that of a membrane. Oil can flow into areas a membrane cannot reach, forming a uniform protective film, suitable for parts stored for long periods, such as large castings, steel materials, construction equipment, and heavy machinery components.

VCI rust preventive oil also boasts very high durability. If your product will be stored for one or two years, or even longer, oil-based rust prevention will offer greater stability. Especially for large steel parts, anti rust film alone is insufficient for complete protection; oil's adhesion and weather resistance are significantly stronger.

V. How to Determine Which Rust Prevention Product to Use?

Many people struggle with choosing between oil and membrane. In reality, you only need to consider a few core questions: How long do you need protection? What is the storage environment like? How high are the product cleanliness requirements? Are there weight and transportation cost restrictions? How complex is the structure?

Generally speaking, if you want something clean, lightweight, suitable for export, and easy to operate, then anti rust film is definitely your ideal choice. Especially for exports to humid countries like Southeast Asia, anti rust film is both lightweight and efficient, greatly reducing risk. However, if the product you need to protect is large, complex in structure, and has a long storage period, or if you are dealing with heavy industrial customers, then VCI rust preventive oil is a more reliable option. Even in some extreme environments, dual protection with oil and film is possible; for example, applying oil first and then sealing with a film will provide even more reliable protection. As experts in rust prevention, CVCI produces various rust-preventive oils and films, and can also recommend combinations tailored to your specific needs. Please contact us at cvci-gaoxiu@chinavci.com for the latest rust prevention industry information and products.