Which Metal Parts Are Suitable for Treatment with VCI Oil?

2025-12-09 17:32Many factories consider pre-packaging rust prevention treatment a necessary step. Which metal parts are best suited for rust preventative treatment? Under what circumstances should China VCI Anti Rust Oil be used?

Why use China VCI Anti Rust Oil before packaging?

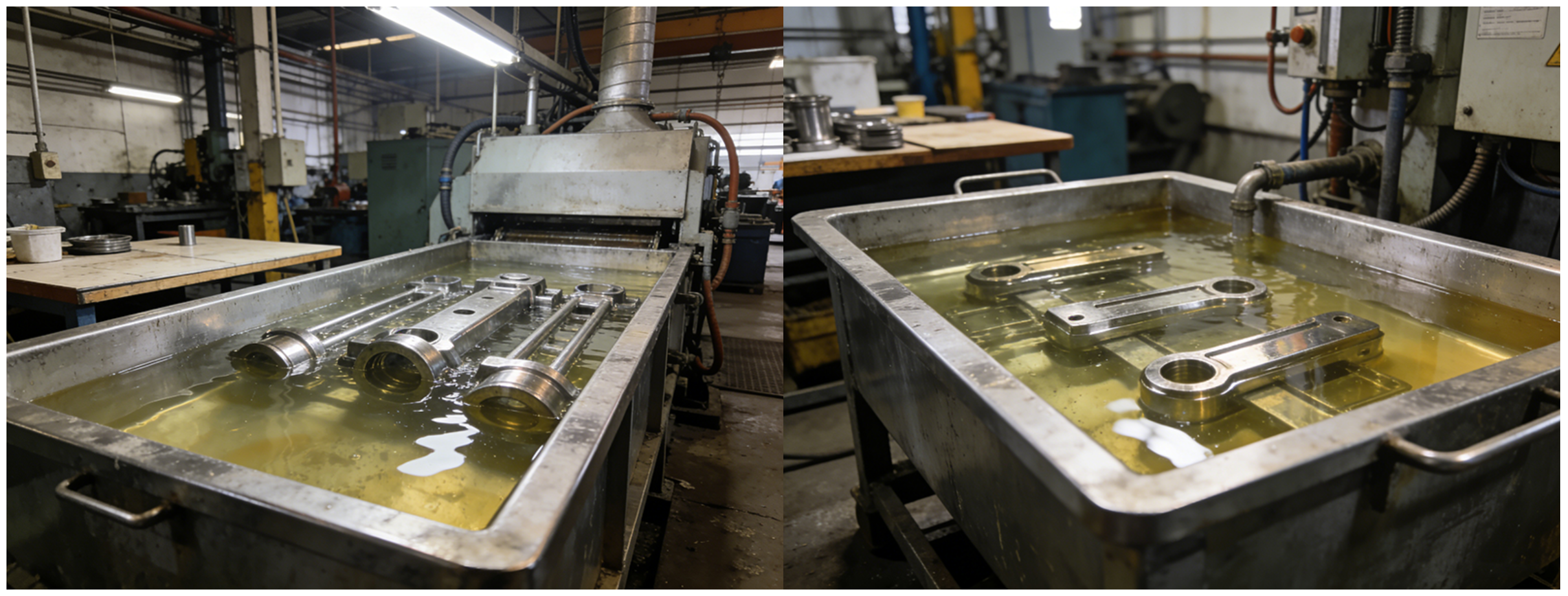

Let's consider a common scenario: a batch of machined parts has just completed precision testing and is waiting in the warehouse for packaging. Large temperature fluctuations during the day and high humidity at night, or frequent opening of warehouse doors during loading, can cause moisture in the air to condense on exposed metal surfaces, potentially leading to dark spots within a few hours. This is especially true for goods shipped by sea, where temperature fluctuations inside the container are even greater, and the so-called "container rain" is more likely to wet the metal. Using rust preventative liquid before packaging effectively seals off the risk window, switching the goods from an exposed risk state to a controlled protection state. For orders exported to hot and humid regions like Southeast Asia, this step is almost essential.

Which metal parts are best suited for rust preventative treatment before packaging?

The general principle is: any exposed metal, precision mating surfaces, parts prone to corrosion, or parts that are high-value and difficult to repair should be prioritized. Specifically, the following types of parts are particularly suitable for China VCI Anti Rust Oil treatment:

Machined precision parts, such as gears, splines, connecting rods, and precision shafts. These parts require high surface finish, and any tiny pitting will affect fit and service life. Using China VCI Anti Rust Oil forms a uniform protective layer on the surface without altering dimensional tolerances.

The bare metal surfaces of bearings, needle rollers, and internal bore parts. It should be noted that if the bearing itself has already been pre-lubricated, large-area immersion in oil-based agents is not recommended; however, for bare bearings or bushings requiring short-term storage, thin-film rust preventative liquid or China VCI Anti Rust Oil can provide short-term protection and is easy to clean or assemble directly after unpacking (depending on the type of oil).

Fasteners and small hardware, such as bolts, nuts, and washers. These parts are numerous, have small surface areas, and are loosely packaged, making them prone to friction and exposure points within the box. Spraying or dipping them in China VCI Anti Rust Oil and then packaging them in separate compartments can significantly reduce the probability of rust. Large castings and chassis structural components are characterized by their large size, numerous welds, and repair points. For long-term transportation or storage, it is recommended to use China VCI Anti Rust Oil localized coating, combined with vapor phase corrosion inhibition or film packaging protection.

For parts that need temporary storage before surface treatment, such as workpieces to be electroplated or painted, using low-residue, easily degreased China VCI Anti Rust Oil protection before packaging and transportation can prevent rust and facilitate subsequent processing.

Types of Rust Inhibitors and Selection Considerations

Common China VCI Anti Rust Oil on the market are generally divided into three categories: volatile/no-clean type (VCI type), conventional oil film type, and heavy-duty/long-term storage type. The volatile type has the advantage of low residue and no need for cleaning, making it suitable for export assemblies; the ordinary oil film type is suitable for long-term exposure but requires cleaning before assembly; heavy-duty protection is mainly used for large parts stored outdoors or for long periods.

When selecting, attention should be paid to compatibility with subsequent processes. If the parts require subsequent painting, electroplating, or precision assembly, prioritize low-residue or washable rust inhibitors, and set up a rapid degreasing process on the assembly line. If bearings have already been greased, avoid overall immersion to prevent affecting the lubricant performance.

Common Misconceptions and Q&A

There are two common misconceptions: firstly, "the thicker the rust-proof oil, the better," but the truth is that a thin and even oil film is more effective and does not affect assembly; secondly, "all bearings cannot be oiled," but this depends on the bearing type and lubrication requirements. Bare bearings can be treated with a light film for short-term storage, but pre-lubricated bearings should not be repeatedly immersed in oil. Some companies are also concerned about environmental protection and odor issues. It is recommended to prioritize low-VOC formulas that have passed SGS/REACH certification, which are both compliant and reduce customer complaints.

CVCI's Practical Experience in the Southeast Asian Market

As a long-term supplier of rust prevention solutions, CVCI's China VCI Anti Rust Oil and VCI films and desiccants have numerous engineering cases in Vietnam, Malaysia, the Philippines, and other places. Customers there generally report that after adopting standardized rust prevention treatment processes before packaging, the rate of damage upon unpacking and customer complaints have significantly decreased, especially during the rainy season and peak shipping periods. We also provide the "most economical combination solution" based on the material of the customer's products, transportation route, and storage period. For example, we recommend volatile China VCI Anti Rust Oil+ VCI bags for exported automotive parts; and China VCI Anti Rust Oil+ anti-rust film + desiccant for large castings.

As a professional manufacturer of anti-rust products, CVCI has many years of experience in export cooperation. Please feel free to contact us via cvci-gaoxiu@chinavci.com for professional guidance on selecting the right anti-rust products.