Is VCI Stretch Film Effective for Rust Prevention of Copper?

2026-02-13 10:58Along with rising demands of metal material in the world industrial supply chain, rust prevention solutions for specific metals have attracted the most attention of the industry. Especially with copper and copper alloys—two critical materials that are widely used in the electronics, electrical, automotive, and construction industries—traditional rust prevention methods are often limited. At present, we are going to discuss a very relevant question: Can VCI rust-preventing stretch film be effective for rust prevention of copper? Yes, it is, and we will explain it below.

Unlike steel, copper corrosion primarily manifests as oxidation and discoloration (producing verdigris) rather than red rust, but this still affects its conductivity, weldability, and appearance. Copper products are particularly susceptible to surface degradation in humid, sulfide-containing environments. Components made of copper that are precise and used in different applications like electronic connectors, transformer windings, and heat exchanger piping, need to be of very high surface purity; in fact, even a small amount of oxidation can cause them to fail in their function.

Our VC Stretch Film: A Protective Technology Designed for Multiple Metals

Our VCI Stretch Film has an advanced vapor-phase corrosion inhibitor formula that is very specially made to give maximum protection to pretty much all kinds of metals such as copper, copper alloys, aluminum, and steel. Its main technological features are:

1. Targeted Formula Design: Our VCI masterbatch formula is carefully formulated to ensure that the released corrosion-inhibiting gas molecules form a stable protective layer on the copper surface, effectively blocking moisture, oxygen, and corrosive substances in the air (such as sulfides) from contacting the copper. Compared to traditional physical barrier methods, this vapor-phase protection can penetrate gaps and complex structures that stretch film cannot completely seal.

2. Multiple Protection Mechanisms

Vapor Phase Corrosion Inhibition: VCI molecules continuously volatilize, forming a protective atmosphere inside the packaging.

Physical Barrier: High-density LDPE film provides excellent waterproof and moisture-proof barriers.

Self-Adhesive Sealing: Unique self-adhesive properties ensure tight packaging, preventing the intrusion of external contaminants.

Three Major Application Advantages for Copper Products

Advantage 1: Highly Effective Protection, Long-Term Stability

Our VCI Stretch Film provides 12-24 months of protection for copper and copper alloys, particularly suitable for:

Electronic Components: Protecting precision copper parts such as circuit board connectors and terminals

Electrical Equipment: Critical components such as transformer copper windings and busbars

Automotive Parts: Copper automotive parts such as radiators and brake lines

Architectural Hardware: Decorative copper materials, pipe fittings, etc.

Advantage 2: Easy Operation, High Adaptability

VCI Stretch Film is offered in two main models:

SF Series: A general-purpose film, ideal for the rust-proof packaging of most copper products.

DF.JC Series: A reinforced film that can accommodate higher VCI concentration and having higher tensile strength. It is a good option for the sea transport of the copper products over long periods or highly corrosive environments.

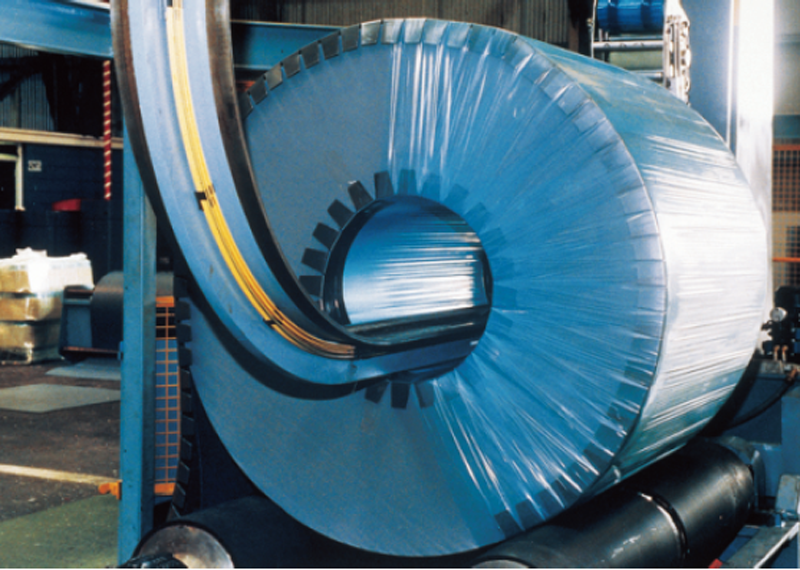

The products can be changed into blue roll form. Dimensions of width and thickness can be altered according to the customer’s needs so as to get the perfect fit:-

Automated Packaging Lines: Designed to be used for the continuous packaging of large volumes of copper coils and tubes.

Manual Winding Operation: Designed to be used for the flexible packaging of irregularly shaped parts and small batches of products.

Hybrid Metal Packaging: Simultaneous protection for copper-steel and copper-aluminum assemblies.

Whether you are packaging delicate electronic copper parts, large copper tubes and plates, or complex copper alloy components, our professional technical team can provide you with customized rust-proof packaging advice and solutions. In the field of metal protection, targeted protection is the most effective—and for copper, choosing VCI Stretch Film designed specifically for multi-metal applications is undoubtedly a wise and professional choice.