VCI Rust-Proof Paper Protects Automotive Parts During Long-Term Storage

2026-02-10 10:40In the automotive industry, the prevention of rust on parts during storage is a major issue that is very rarely taken into consideration. It is to be assumed that metal parts, such as engine blocks, precision bearings, brake discs, or drive shafts, are exposed to corruption constantly during their storage and transportation. Traditional rust prevention methods with the use of oil are not only time-consuming and environmentally polluting, but also lead to increased costs for cleaning processes later on.Today, a more efficient and environmentally friendly solution is being adopted by leading global automakers and suppliers—VCI (Vacuum Phase Corrosion Inhibitor) rust-proof packaging paper.

Our VCI Rust proof paper uses an advanced process to uniformly impregnate VCI onto ordinary or corrugated neutral base paper, then laminates a high-density PE film onto the surface. This novel design results in an "active protection" surrounding at a micro scale: VCI molecules are constantly released into the atmosphere of the packaging as they evaporate from the paper, and they subsequently form a protective single-molecular layer on the component surface thereby the VCI molecules do not have direct contact with the metal surface, effectively preventing moisture, oxygen, and other corrosive agents from the metal.

VCI technology gives "all-around, no-dead-angle" protection, unlike rust-preventive oils that have to be applied directly. It ensures even protection of complicated shapes, grooves, holes and cavities. This protective mechanism is especially suitable for the kind of metal composite parts in car components, e.g. steel and aluminum assemblies.

Four Core Advantages:

1. Our VCI rust-preventive paper, in accordance with QB/T 1319 and JIS Z 1535 standards, has undergone rigorous salt spray testing and provides continuous rust protection for carbon steel, alloy steel, cast iron, and aluminum products for over 24 months. The PE coating further enhances its waterproof and moisture-proof properties, ensuring stable protection even in humid storage environments.

2. Traditional rust-preventive oils require application, drying, and degreasing before use, a time-consuming and labor-intensive process. Applying VCI rust-preventive paper is extremely simple: just wrap the parts or place them in a sealed package with the paper, and the rust-prevention process begins automatically.

3. With increasingly stringent global environmental regulations, the automotive industry is placing higher demands on green supply chains. Our VCI rust proof paper is free of harmful substances such as nitrites, complies with RoHS and REACH environmental standards, and provides a fully recyclable, environmentally friendly packaging solution.

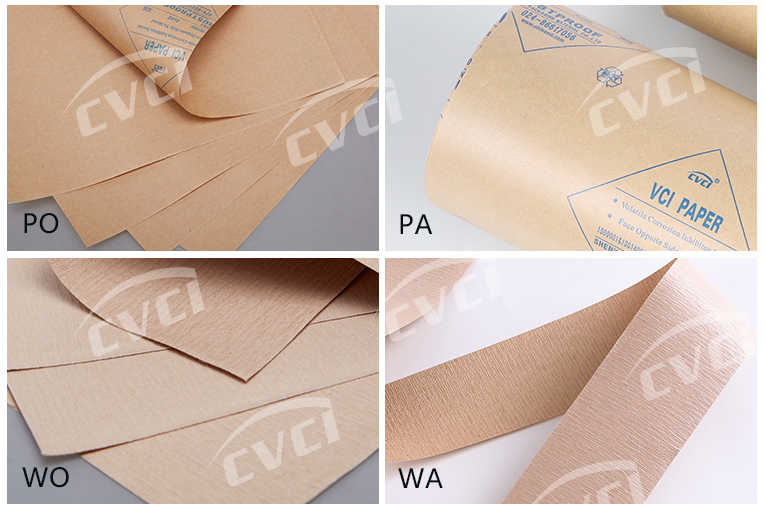

4. Automotive parts are diverse in type, size, and shape. We offer a wide range of VCI rust proof paper widths from 100mm to 2000mm, as well as custom-sized services, ensuring proper packaging for everything from tiny fasteners to large vehicle frames.

Industry Application Example:

A manufacturer supplying braking systems to European automotive brands faced a serious challenge: approximately 15% of cast iron brake components developed surface corrosion during sea freight to European customers, leading to returns and claims. After adopting our VCI rust-protective paper solution, they implemented the following improvements:

• Optimized packaging process: After cleaning and drying the parts, they are directly wrapped in VCI paper and sealed in polyethylene bags.

• Adaptability to storage environments: Even in high-salt, high-humidity sea environments, the PE-coated VCI paper maintains its protective effect.

• Customer feedback: Ready to use upon arrival, with no residue or contamination, improving assembly line efficiency.

After 12 months of implementation, the supplier's rust-related return rate dropped to below 0.5%, while packaging labor costs decreased by 35%, earning them the "Supplier of Excellence" certification from their customer.