Is VCI Film Suitable for Auto Parts?

2025-09-28 08:581. Difficulties in Storing Automotive Chassis Parts

Automotive chassis parts are primarily made of steel and alloys, with large surfaces and complex structures, often resulting in difficult-to-access edges and corners. During storage, these parts are highly susceptible to environmental factors. For example, humidity in the air constantly clings to metal surfaces, especially during high humidity seasons, accelerating oxidation. This rust risk is even more severe for parts that require long-term storage, and rust can even develop before transportation begins, resulting in significant losses.

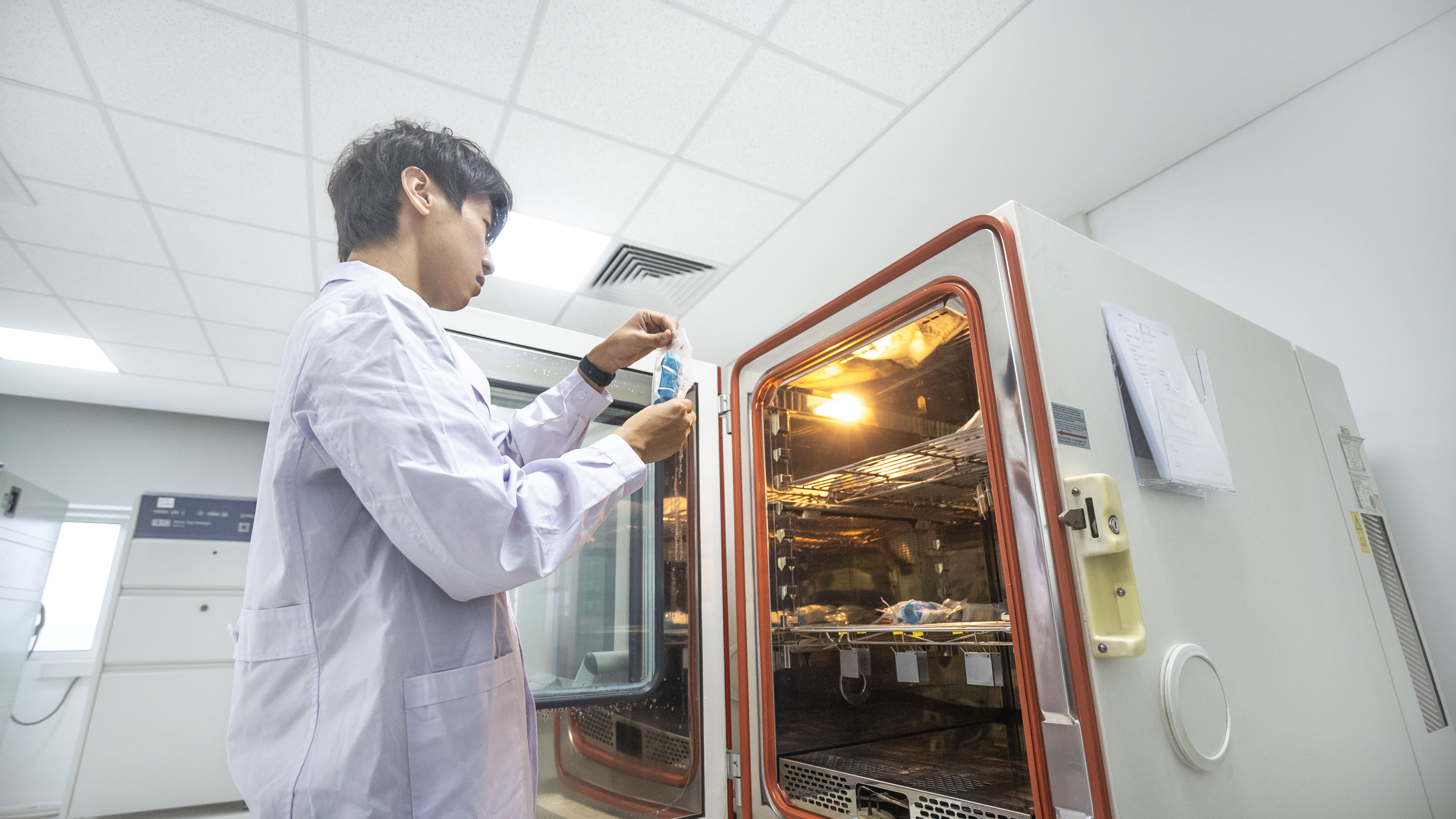

2. How China Safe VCI Film Works in Parts Storage

VCI Anti Static Film is a polymer packaging material with a VCI component added to the film. VCI Anti Static Film's protective properties go beyond simply keeping out air. During use, VCI Anti Static Film gradually releases VCI molecules, which diffuse within the enclosed space and adsorb onto the metal surface, forming an invisible molecular protective layer. This protective layer effectively blocks direct contact between corrosive media such as oxygen, moisture, and chloride ions, fundamentally slowing the rust process. Compared to ordinary plastic film, VCI Anti Static Film offers both chemical and physical isolation, providing consistent protection for parts for months or even longer. The VCI Anti Static Film produced by CVCI has undergone multiple laboratory tests to ensure that it can achieve excellent rust resistance and last longer than other similar products.

3. Advantages of VCI Anti Static Film over Traditional Methods

VCI Anti Static Film offers unique advantages over traditional rust-proofing oils, desiccants, or ordinary plastic wrap. While rust-proofing oils can form a protective film, they require manual application and subsequent cleanup, consuming significant labor and solvents. Desiccants, while moisture-absorbing, cannot directly protect the surface of parts and require large quantities to cover the entire storage environment. Ordinary plastic wrap simply seals out air and remains ineffective against rust if condensation forms. In contrast, VCI Anti Static Film is not only convenient to use and requires no cleanup after wrapping, but also provides active protection through VCI molecules, providing comprehensive and long-lasting protection, significantly reducing the risk of part scrap and rework.

4. Application Cases for Automotive Chassis Parts

In practice, VCI Anti Static Film has been widely used in the storage and transportation of automotive chassis parts. In storage, parts are sealed with VCI Anti Static Film immediately after leaving the production line, ensuring a pristine surface finish for weeks or even months. For parts destined for export, China Safe VCI Film effectively withstands the complex and fluctuating humidity and temperature conditions of ocean shipping, preventing surface rust caused by "container rain." Even with long-term inventory management, China Safe VCI Film ensures that parts remain in stable condition during after-sales service. After adopting CVCI's China Safe VCI Film packaging for auto parts, one of our automotive parts manufacturers saw a 40% reduction in rust-related returns and a significant increase in customer satisfaction, demonstrating the effectiveness of our China Safe VCI Film in preventing rust on auto parts.

5. Why Choose VCI Anti Static Film from CVCI?

Among numerous anti-rust film suppliers, CVCI, with its robust factory infrastructure and comprehensive quality certifications, has become the preferred partner for many global automotive parts manufacturers. CVCI's modern production facility, equipped with advanced film blowing and laminating equipment, ensures high-quality and stable supply of China Safe VCI Film. Our products are ISO9001 certified and comply with international environmental standards such as RoHS and REACH, ensuring global compliance with environmental and safety requirements. With extensive export experience, CVCI's China Safe VCI Film has been successfully sold to over 40 countries, establishing long-term partnerships with many renowned automotive parts manufacturers. We also offer customized China Safe VCI Film products in various specifications, thicknesses, and formats, meeting diverse application scenarios from warehousing to export and transportation.

Conclusion:

For automotive chassis parts, rust prevention during storage is crucial, and China Safe VCI Film is a highly suitable option. China Safe VCI Film not only provides long-lasting and stable protection, but also simplifies operational processes and reduces overall cost of ownership. As a professional anti-rust film manufacturer, CVCI will continue to leverage its advanced production capabilities and comprehensive quality assurance system to provide highly effective, environmentally friendly, and cost-effective China Safe VCI Film products to customers worldwide. We welcome interested customers to contact us at cvci-gaoxiu@chinavci.com for professional anti-rust advice, helping you achieve optimal rust protection for your automotive parts.

Reference:

ISO 9001:2015 Quality Management Systems Standard.

European Chemicals Agency (ECHA) – REACH Regulation.

SAE International – Corrosion Protection Standards for Automotive Parts.

Industry Case Studies on VCI Film Applications in Automotive Logistics.