What Products Are Suitable for Spraying VCI Antirust Fluid?

2025-09-27 14:17In the metallurgical industry chain, products such as steel, castings, forgings, pipes, and profiles often undergo multiple stages of production, warehousing, transportation, and export. During these stages, moisture, oxygen, salt spray, and condensation from temperature differences in the air can be major factors in the development of corrosion. Metallurgical products are particularly susceptible to rust during cross-border shipping or storage and transportation across climates. To effectively delay rust and ensure product quality, applying china water based antirust fluid to the metal surface is an excellent option. However, which metallurgical products are suitable for china water based antirust fluid spraying?

I. Why do metallurgical products require china water based antirust fluid coating?

The metallic properties of metallurgical products susceptibly cause chemical reactions with oxygen and moisture, leading to oxidation when exposed to air and moisture. Ordinary carbon steel products, in particular, are prone to rusting when humidity exceeds 60%. The rate of corrosion is significantly accelerated when exposed to salt spray during transportation.

If effective protective measures are not taken, rust on the steel surface not only affects the metal's appearance but can also degrade product performance and even affect subsequent processing accuracy. Spraying China water based antirust fluid on metal surfaces effectively addresses rust issues. China water based antirust fluid forms a transparent protective film on the metal surface, insulating it from corrosive agents.

II. Scope of Application of China water based antirust fluid

China water based antirust fluid can be applied to a wide range of products and is easy to use, suitable for a variety of metallurgical products:

China VCI antirust fluid is suitable for bulk materials such as steel plates, steel pipes, H-beams, and angle steel. These products often have large exposed areas during large-scale transportation and storage. Spraying China VCI antirust fluid quickly creates a uniform protective layer.

China VCI antirust fluid can also be used on semi-finished products and blanks. For example, castings and forgings often require transit or storage before machining. Without protection, their surfaces are prone to oxidation. Spraying China VCI antirust fluid effectively slows down this oxidation process.

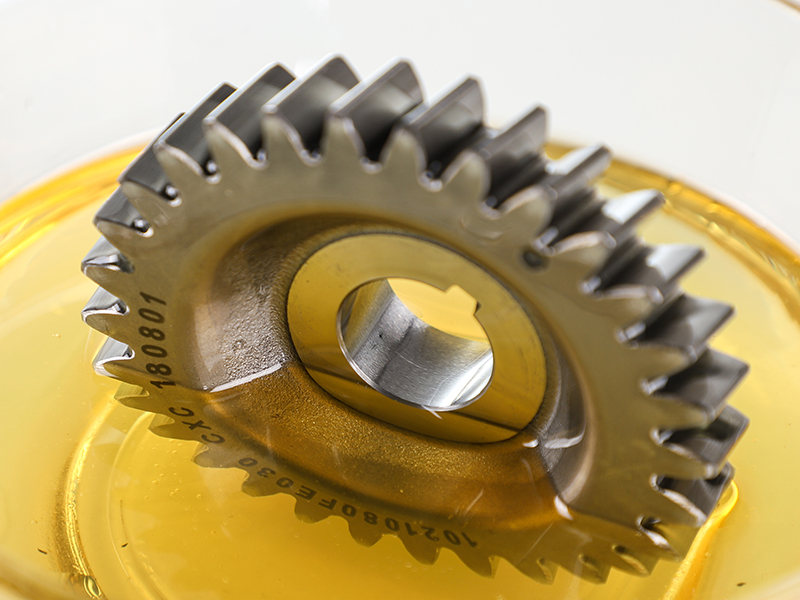

Precision components: Gears, bearings, flanges, and other components require high surface precision, and even the slightest pitting can render them useless. China VCI antirust fluid provides short-term protection without the difficult cleanup requirements of rust-proof oils.

Wire and coiled materials: Products such as steel wire and coiled wire are large in quantity and complex in shape, making individual protection challenging. Spraying China VCI antirust fluid on the surface and then applying an anti-rust film can reduce the overall risk of rust.

Thus, China VCI antirust fluid can meet nearly every requirement in the metallurgical industry, from raw materials to finished products.

Ⅲ. Advantages and Value of China VCI antirust fluid

Compared with traditional anti-rust methods, VCI antirust fluid has obvious advantages:

| Easy application | Simply spray-coat, suitable for high-volume production on assembly lines. |

| Uniform coverage | Permeates corners and complex structures, creating a uniform protective film. |

| Environmentally compliant | Compliant with RoHS, REACH, and other environmental standards, ensuring minimal environmental impact. |

| Cost-effective cleanup | No degreasing or cleaning required, allowing for direct processing. |

| High cost-performance | Reduces returns and scrap, lowering overall protective costs. |

IV. Typical Application Industries and Case Studies

CVCI's VCI antirust fluid products are finding practical application in a variety of industries, including metallurgy, machinery manufacturing, automotive parts, and hardware. For example, our metallurgical customers spray-coat our VCI antirust fluid products in bulk upon steel production and storage, ensuring rust-free storage. Automotive parts such as gears, brake discs, and vehicle frames are sprayed with VCI antirust fluid and then wrapped with anti-rust paper or film for export by sea. This combined rust prevention offers enhanced effectiveness. For example, after implementing our VCI antirust fluid products, an automotive parts exporter saw a 30% decrease in product returns, a significant reduction in after-sales disputes, and a significant increase in customer satisfaction. This is a testament to the practical value of our VCI antirust fluid products, and we are delighted to see that our customers have benefited from our rust-proofing products.

V. Usage Precautions

To maximize the effectiveness of the rust preventative, please note the following points during the spraying process:

Surface Preparation: Before spraying China VCI antirust fluid, ensure the metal surface is clean, free of oil, dirt, and moisture.

Spray Thickness: Apply China VCI antirust fluid evenly, avoiding either too thin a layer (which may result in insufficient protection) or too thick a layer (which may affect subsequent processing).

Environmental Conditions: Application is best in a dry environment; avoid spraying China water based antirust fluid in high humidity.

Storage Period: Depending on the China water based antirust fluid formulation, the protection period can range from several months to a year. The appropriate product should be selected based on shipping and storage time. CVCI's professional engineers can provide you with specialized rust prevention solutions. Simply provide your product and the desired protection period, and we will customize a solution based on your specific needs.

Conclusion:

As international market demands for product quality and environmental compliance continue to rise, China VCI antirust fluid is becoming a crucial protective material in the metallurgical industry. China VCI antirust fluid is suitable not only for bulk materials like plates and pipes, but also for precision components and wire and coils. Compared to traditional methods, rust preventative liquids are more convenient, more environmentally friendly, and more economical. If you require high-quality VCI antirust fluid or other rust preventative products, please feel free to contact us at cvci-gaoxiu@chinavci.com for professional rust prevention advice and high-quality products.

References:

1. ISO 9001 Quality Management System Standard

2. RoHS and REACH Environmental Regulations

3. "Metallurgical Product Protection Technology Application Manual," Metallurgical Industry Press, 2022

4. CVCI Anti-Rust Liquid Customer Application Case File, 2024