Is It Necessary to Use VCI Oil Before Assembling Wind Turbine Components?

2026-01-13 17:08Why is rust prevention particularly important for wind turbine hub components?

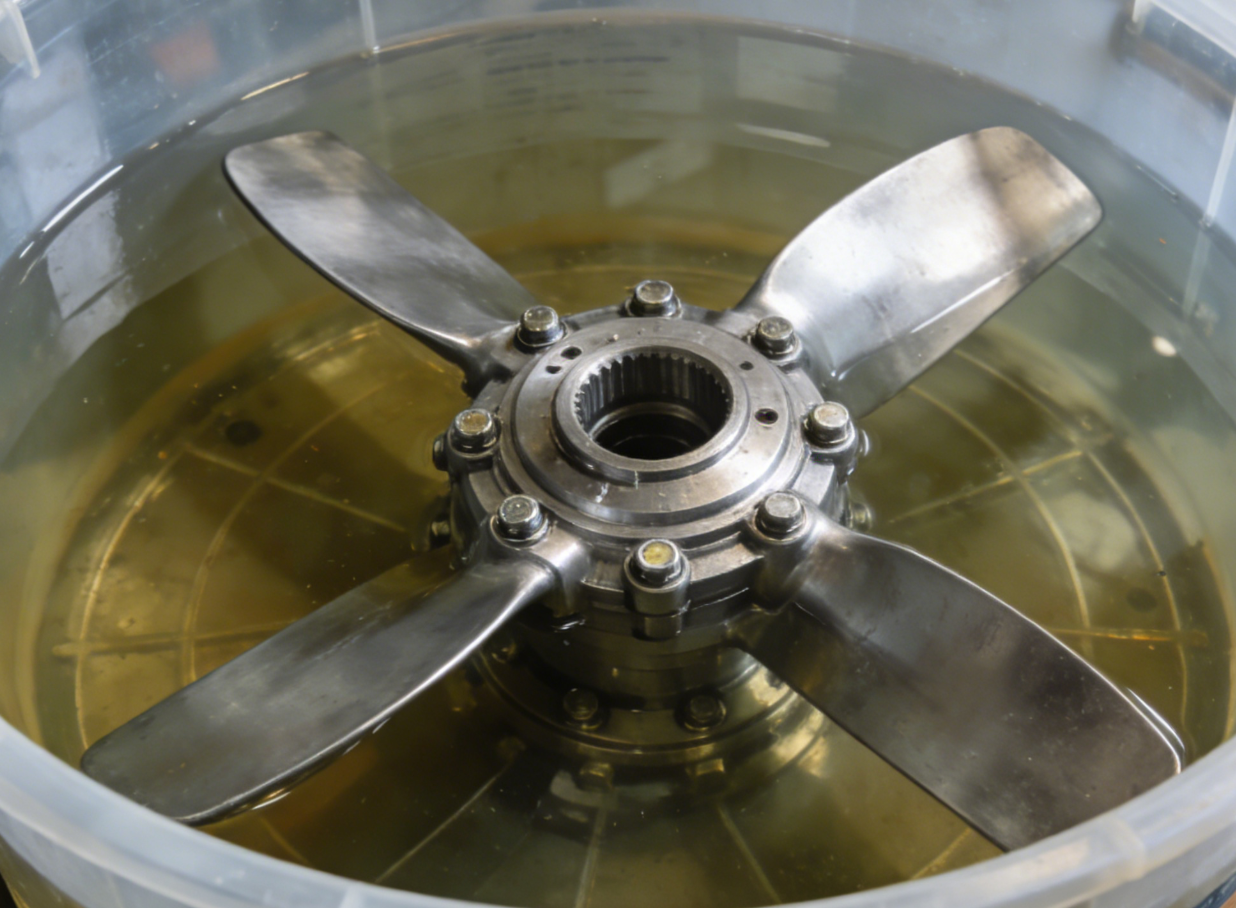

Hub components are large and have thick walls, appearing robust and durable, but their processing and handling cycles are often very long. From machining completion to inspection, waiting for assembly, and then integration into the complete machine, the process can involve weeks or even months of exposure time.

During this process, workshop humidity, seasonal changes, and delays between processes can cause the metal surface to repeatedly come into contact with moisture. Even slight oxidation over a short period, if not addressed promptly, can lead to corrosion of the assembly surface and bolt holes, and even affect assembly accuracy. In its collaborations with several wind power component companies, CVCI has found that many assembly problems do not occur on-site, but rather stem from a lack of systematic rust prevention control in the early stages.

What are the hidden risks of not performing rust prevention treatment before assembly?

On the surface, slight surface rust may seem insignificant, but during assembly, it can directly lead to unstable torque, uneven contact surfaces, and even affect long-term service reliability. This is especially true for high-load, high-fatigue components like wind turbine hubs, which are very sensitive to assembly quality. Once corrosion is discovered, grinding, cleaning, and rework not only increase costs but also disrupt the assembly schedule. In contrast, a standardized treatment with China VCI Anti Rust Oil before assembly is much more controllable.

What are the practical effects of using China VCI Anti Rust Oil on wind turbine hub components?

After proper coating or spraying, the hub components will form an extremely thin rust-preventive protective film on the surface. This inhibits corrosion without affecting dimensions or assembly fit. Even when stored in high-humidity environments for short periods, the surface condition remains controllable. In CVCI's export projects, many customers uniformly apply China VCI Anti Rust Oil before assembly to ensure that different batches of components have consistent surface conditions when entering the assembly line.

Is rust inhibitor important in export projects?

When exporting wind power equipment and components to Southeast Asian markets, one of the biggest challenges is the high-temperature and high-humidity environment. Even during the short waiting period before assembly, oxidation problems can occur without rust prevention measures.

CVCI's rust inhibitor products have been exported to many countries and regions, especially in the Southeast Asian market, and have undergone long-term application verification. Many customers have incorporated pre-assembly rust prevention fluid treatment into their internal SOPs as a standard procedure.

What support can CVCI provide in the production and R&D of rust prevention fluids?

As a manufacturer specializing in rust and corrosion prevention solutions, CVCI focuses not only on providing individual products but also on the overall application effectiveness. We have stable rust prevention fluid production capabilities and continuously conduct formula development and application testing to adapt to different working conditions and industry needs. In the wind power sector, we can assist customers in developing more reasonable rust prevention fluid selection and usage methods based on the material, processing status, and storage period of the hub components, avoiding overuse or insufficient protection.

If you are evaluating rust prevention solutions for wind turbine hubs or other large components, please feel free to contact CVCI to discuss your specific working conditions. We also welcome you to visit our factory to learn about our rust prevention fluid production capabilities, R&D processes, and real-world application cases. Face-to-face communication often makes it easier to find the most suitable and reliable solution.