How to Pack Wind Turbine Gears for Sea Transportation?

2025-09-25 10:46In recent years, the export volume of wind turbine equipment has increased annually, especially for large Wind turbine gears, which are in high demand for maritime transport. However, as critical structural metal components, Wind turbine gears are highly susceptible to corrosion from salt spray, moisture, and condensation during the lengthy sea transport process. Preventing rust during these long sea transport periods is a crucial issue.

Why are Wind turbine gears prone to rust during sea transportation?

The ocean shipping process is one of the greatest challenges in protecting metal products. During ocean transportation, metal products are packed in containers. The high concentration of chloride ions in the ocean air accelerates oxidation reactions on the steel surface. Furthermore, when crossing different climate zones, condensation often forms on containers or decks. This, combined with "container rain" caused by temperature fluctuations, causes condensation to drip directly onto the flange surface, further exacerbating corrosion. Furthermore, ocean shipping cycles often last for dozens of days or even months, exposing metals to prolonged exposure to high salt spray and high humidity, making corrosion almost inevitable. Therefore, for large, high-value components like Wind turbine gears, traditional short-term protective measures often fail to meet ocean shipping requirements. China Anti-Rust Film is ideally suited for wrapping and rust-proofing gears during ocean shipping.

What is China Anti-Rust Film and how does it work?

China Anti-Rust Film is a polymer film made with VCI, specifically designed for metal protection. Its core principle is that the rust-resistant molecules in China Anti-Rust Film gradually evaporate and diffuse into a confined space, evenly adsorbing onto the metal surface to form an invisible protective film. This molecular barrier released by China Anti-Rust Film effectively blocks direct contact between moisture, oxygen, and salt in the air and the metal, thereby preventing oxidation reactions. Compared to traditional methods, China Anti-Rust Film not only offers superior rust prevention but also serves a dual purpose of packaging and protection, making it particularly suitable for the rust prevention needs of large equipment such as Wind turbine gears during long ocean transport periods.

How to use China Anti-Rust Film packaging for Wind turbine gear?

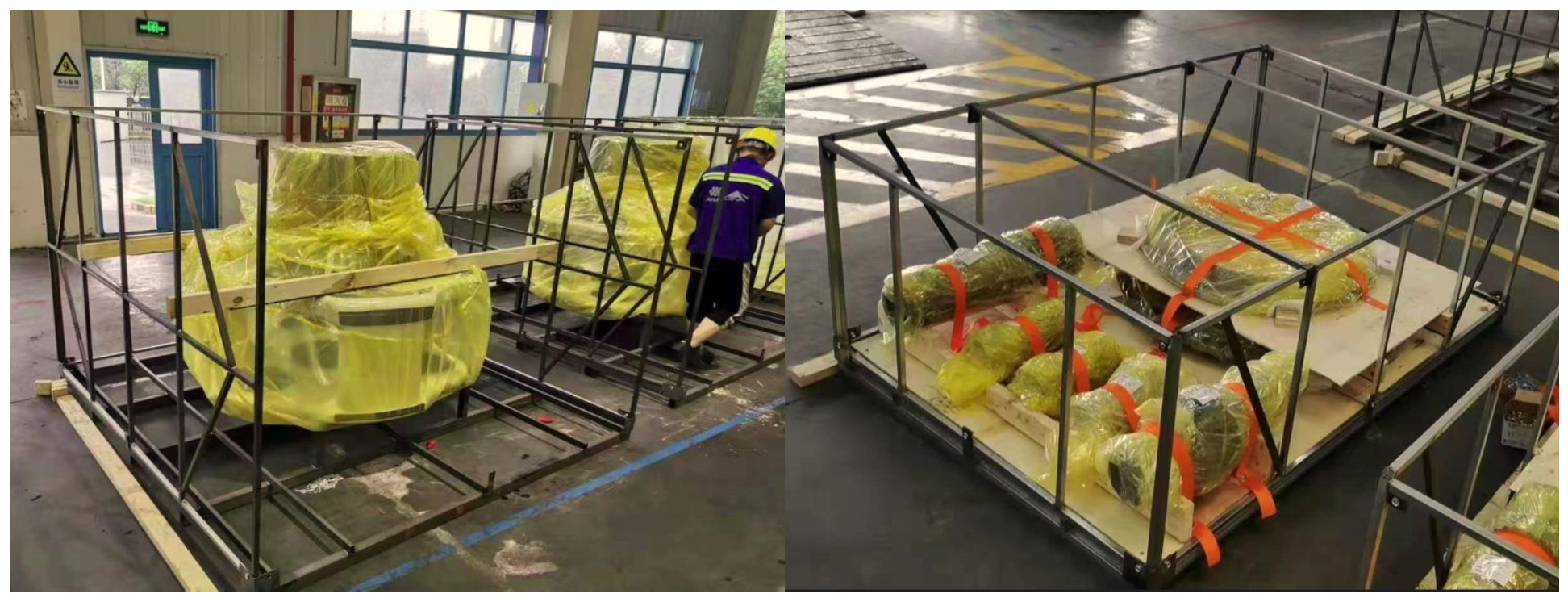

To ensure the best protection for Wind turbine gears during sea transportation, when using China Anti-Rust Film for packaging, the surface must first be cleaned to remove oil, moisture and impurities to avoid residual sources of rust; then the gears must be thoroughly dried to prevent condensation from accumulating; then the gears must be fully wrapped with China Anti-Rust Film and checked for damage; then sealed with sealing tape or heat sealing to block air entry; according to transportation requirements, physical protection such as waterproof cloth or wooden boxes can also be added to the outer layer; finally, clear identification and protection information should be affixed to the outside of the package to facilitate transportation and acceptance.

A wind turbine equipment manufacturer has been exporting large wind turbine gears to Europe for a long time. Previously, they used anti-rust oil and plastic sheeting for packaging, but surface corrosion often occurred upon arrival at the port, leading to customer returns. They later switched to China Anti-Rust Film sealed packaging with an appropriate amount of desiccant. After 60 days of transoceanic shipping, the gear surfaces remained pristine.

Customer feedback indicates that using China Anti-Rust Film not only reduces the risk of corrosion but also reduces cleaning and rework costs, significantly improving delivery satisfaction. This case demonstrates the significant effectiveness of China Anti-Rust Film packaging for ocean shipping of wind turbine gear.

Buyers' biggest concern: Is China Anti-Rust Packaging VCI Film the best choice?

For buyers, choosing a rust prevention solution requires more than just effective protection; they must also balance cost and compliance. VCI anti-rust film offers significant cost benefits, effectively minimizing returns and after-sales risks caused by rust. Furthermore, China Anti-Rust Packaging VCI Film is more time-efficient and labor-saving than traditional oiling, eliminating the need for additional cleanup and reducing numerous steps. China Anti-Rust Packaging VCI Film complies with international standards such as RoHS and REACH, fully meeting the transportation requirements of the European and American markets. Its high adaptability also allows it to be applied to wind turbine gears of various specifications and sizes. Overall, anti-rust film offers outstanding advantages in terms of cost-effectiveness, convenience, and compliance, making it a highly competitive packaging solution.

Conclusion: Is China Anti-Rust Packaging VCI Film a ideal choice for wind turbine gear shipping?

Wind turbine gear faces significant corrosion risks during ocean transportation, and traditional protective measures are unable to withstand the long-term, high-salt spray environment. China Anti-Rust Packaging VCI Film sealed packaging, due to its long-term effectiveness, comprehensiveness, and environmental friendliness, has become the preferred solution for export shipping in the wind turbine industry. Choosing China Anti-Rust Packaging VCI Film is not only an effective way to protect cargo, but also a crucial step for companies to enhance their international competitiveness and secure customer trust.

At CVCI, we are committed to providing efficient, environmentally friendly, and compliant anti-rust solutions to our global customers. Our core products include China Anti-Rust Packaging VCI Film, anti-rust paper, anti-rust liquid, and various composite materials, which are widely used in industries such as automotive parts, machinery and equipment, precision instruments, and wind turbine gear. Leveraging advanced production processes, a strict ISO9001 quality system, and products that comply with international environmental standards such as RoHS and REACH, we help our customers effectively reduce corrosion risks and minimize returns and after-sales costs.

In addition, CVCI, with its experienced R&D team and modern factories, can provide customized anti-rust packaging solutions for various transportation and storage scenarios, combining efficiency and cost-effectiveness. Choosing CVCI means choosing a trusted, long-term partner.

Please feel free to contact us at cvci-gaoxiu@chinavci.com to find the rust prevention solution that's best for your business.

References:

1. ISO 12944 "Standard for Metal Corrosion Protection and Protective Coatings"

2. China Wind Power Industry Association: "Guidelines for International Transport of Wind Power Equipment"

3. White Paper on the Application of VCI Rust-Proofing Materials (2023 Edition)

4. International Chamber of Shipping: "Technical Report on Condensation and Salt Spray Corrosion Protection"