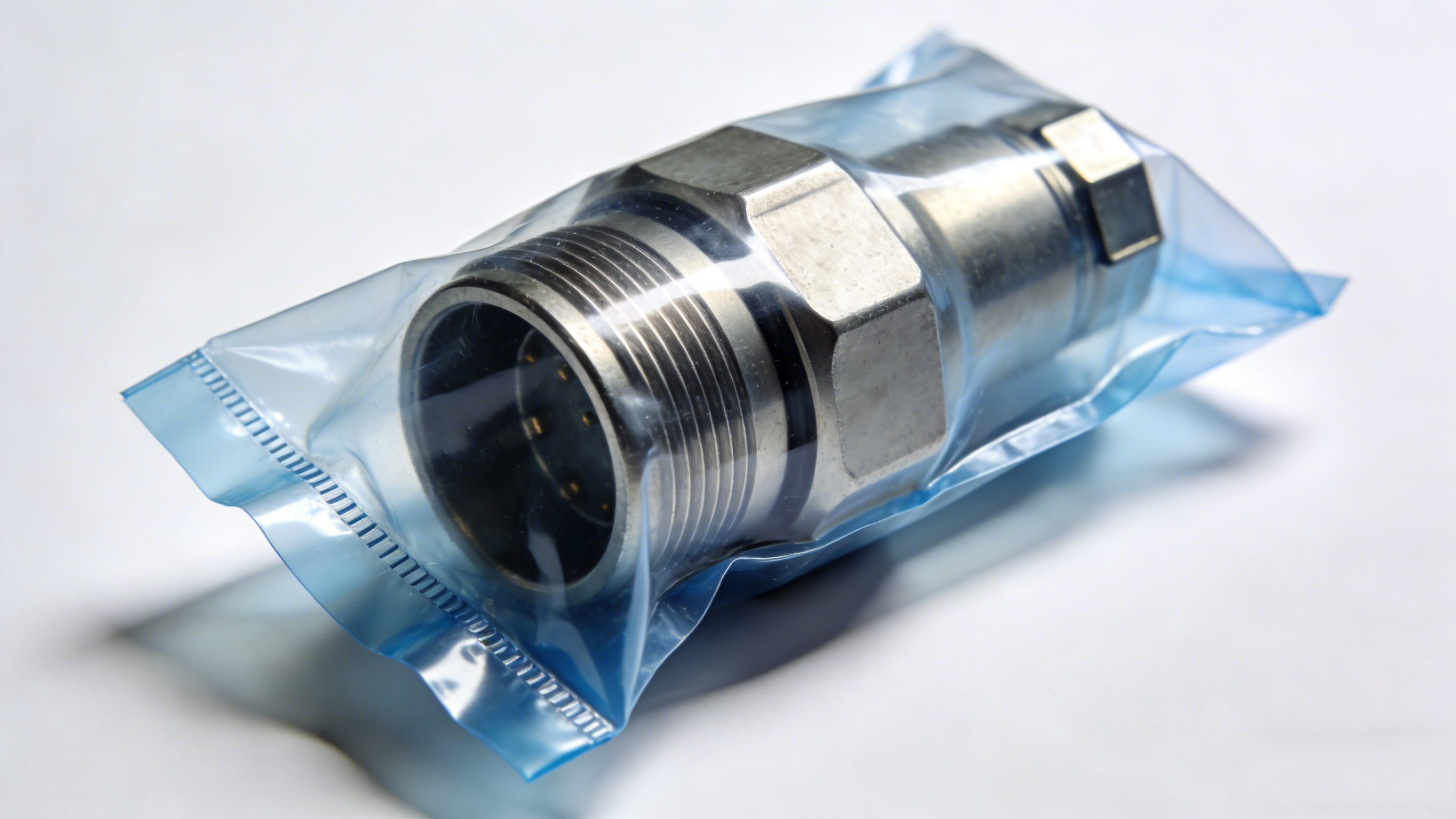

Can Avionics System Connectors Be Sealed and Preserved Using VCI Film?

2026-01-16 17:38In the aerospace manufacturing field, avionics system connectors may seem insignificant, but those who have actually worked on projects know that if these components malfunction, the troubleshooting costs and rework expenses are very high. Many connectors are small, numerous, and frequently handled before assembly, making it easy to overlook rust prevention issues until problems such as contact oxidation and poor contact are discovered during actual use.

Why do avionics system connectors need rust prevention?

Many people have a misconception that because avionics connectors are small and have a surface coating, they are less likely to rust. However, this is not the case. The interior of the connectors often contains metal contacts, springs, and terminal structures, which are extremely sensitive to moisture. Even slight oxidation can affect signal stability.

From manufacturing completion to final assembly, these connectors may undergo multiple stages of storage, transportation, and even international shipping. Especially during the rainy season or in high-humidity environments, even short-term exposure can lead to the formation of an oxide layer at the microscopic level. When CVCI provides rust prevention solutions to aerospace and electronics industry clients, they find that many functional failures are not rooted in design or manufacturing, but rather in insufficient protection during the storage phase.

What risks are faced during storage and transportation?

Unlike large structural components, avionics connectors are usually stored in batches, with small packages densely stacked. If the external environment humidity increases, the internal space can easily form a localized high-humidity environment. If ordinary plastic bags or packaging films are used, they can only isolate dust but cannot prevent moisture from entering.

More realistically, many aerospace projects involve exports, with destinations concentrated in high-temperature and high-humidity regions such as Southeast Asia. During sea or air transport, temperature changes can cause repeated condensation inside the packaging, which is a very unfriendly environment for precision connectors.

What are the practical effects of using VCI anti rust film on avionics connectors?

In practical applications, the advantages of VCI anti rust film for avionics system connectors are mainly reflected in two aspects: "stability" and "gentleness."

Through sealed packaging, the VCI anti rust film releases vapor-phase corrosion inhibitors inside the packaging. These molecules can uniformly diffuse to the surface of the connector, including contacts, gaps, and micro-structural areas, forming a molecular-level protective barrier. Even if the connector surface is not directly coated with any liquid, continuous protection is still achieved. CVCI has provided VCI anti-corrosion film solutions for avionics connectors in numerous export projects. Feedback indicates that the connectors can be assembled directly after unpacking without cleaning, and the surface condition remains stable, which is particularly important for the aviation industry.

What is the main working principle of VCI anti rust film?

The core of VCI anti rust film lies in vapor-phase corrosion inhibition rather than traditional physical encapsulation. The anti-corrosion factors in the film slowly volatilize, forming a protective atmosphere in a sealed or semi-sealed space. These anti-corrosion molecules preferentially adsorb onto the metal surface, changing the electrochemical environment of the metal surface and thus inhibiting corrosion reactions. Even if a small amount of moisture is present in the packaging, the corrosion reaction will be effectively slowed down. When developing VCI anti-corrosion films, CVCI pays special attention to electronic and avionics applications, ensuring that the anti-corrosion factors are effective on metals while not adversely affecting plastics, rubber, or electronic materials.

Will sealing and storing with VCI anti rust film affect the performance of avionics connectors?

This is the most concerning question for many aviation customers. Based on practical experience, properly selected VCI anti rust film will not affect the electrical performance of the connectors. The anti-corrosion molecules do not form visible residues and do not leave oil films or deposits on the contact surfaces.

In CVCI's product testing and customer feedback, connectors stored with VCI anti rust film showed no abnormal contact impedance or signal attenuation problems during assembly and power-on testing. This is an important reason why VCI anti-corrosion materials are gradually being accepted in the aviation and electronics industries.

What support can CVCI provide in VCI anti rust film production and R&D?

As a professional manufacturer of anti-corrosion materials, CVCI has stable VCI anti rust film production capabilities and continuously invests in R&D resources to optimize solutions for different industries and application scenarios. We focus not only on anti-corrosion effects but also on material compatibility and safety of use. In the field of avionics and electronics applications, CVCI will provide more suitable VCI anti rust film solutions based on the customer's storage period, packaging method, and export environment, avoiding the simplistic approach of using one material for all scenarios.

If you are evaluating anti-corrosion solutions for avionics system connectors or other precision components, please feel free to contact CVCI. We can work with you to clarify the anti-corrosion solution based on your specific application scenario. We also warmly welcome you to visit our factory to learn about our VCI anti rust film production capabilities, R&D processes, and real-world export cases. Face-to-face communication often makes it easier to find safe, reliable, and long-term feasible solutions.