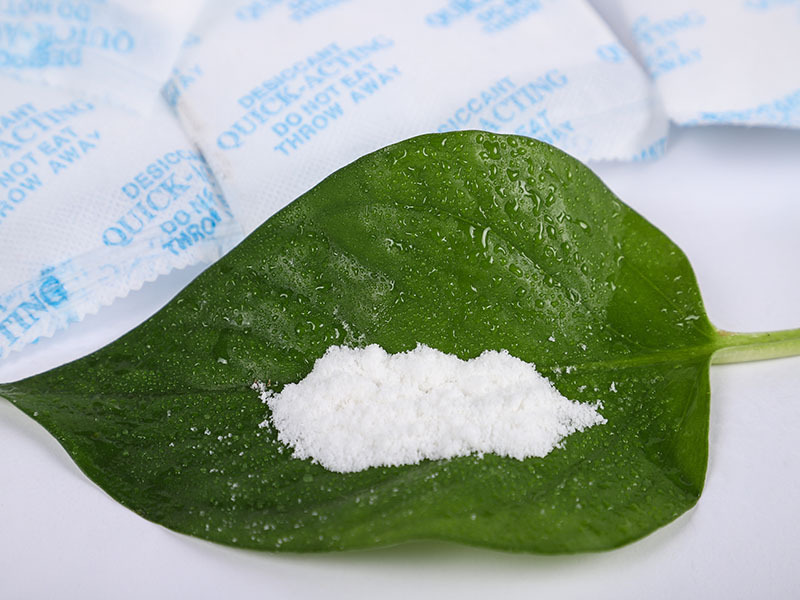

Quick acting Desiccant

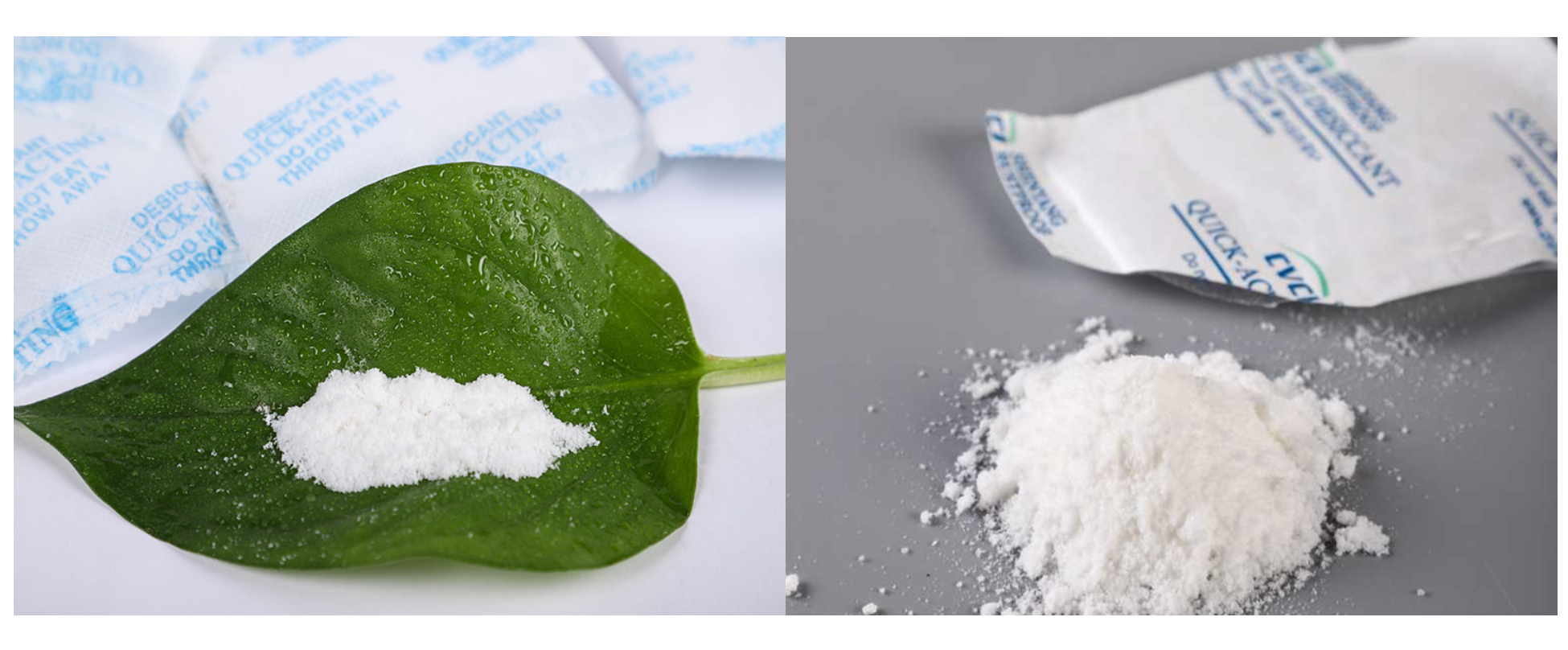

1. Dry Fast Desiccant Sachets contains no chloride ions and is compatible with aluminum;

2. Dry Fast Desiccant Sachets exhibits no contact corrosion;

3. Recommended application rate for Dry Fast Desiccant Sachets is 200g/m³.

- CVCI

- China

- 14 days after payment

- 1500 tons per month

- Information

Product Introduction of Desiccant sachets:

Desiccant sachets are made from a variety of highly effective active adsorbents, precisely calculated and scientifically formulated to ensure absolute product safety. Quick acting Desiccant offers a comprehensive range of specifications to meet the moisture- and rust-proof packaging needs of various products.

Applications of Desiccant sachets:

Quick acting Desiccant is widely used in a variety of industries, including electronics, metal products, precision machinery, communications equipment, military products, building materials, and instrumentation. During the production, storage, and transportation of these products, moisture and corrosion often severely impact product performance and quality. Through efficient drying and rust-proofing, CVCI's Quick acting Desiccant effectively reduces humidity, blocks the intrusion of moisture and corrosive media, and thus maintains product stability and reliability, extending its service life. CVCI also offers customized solutions tailored to the needs of various industries, drawing on industry experience and professional testing, ensuring safe and reliable protection even in complex environments.

How to use Quick acting Desiccant:

Before using Quick acting Desiccant, carefully inspect the sealed bag for damage.

Remove the Quick acting Desiccant from the carton and remove the plastic bag.

Place an appropriate amount of moisture absorber sachets into the product packaging.

Seal the product packaging as soon as possible.

Store any remaining moisture absorber sachets in a sealed container as soon as possible.

Moisture absorber sachets Storage Requirements

Moisture absorber sachets should be stored in a cool, dry environment, avoiding mixing with chemicals to prevent unwanted reactions. Also, the outer packaging of the moisture absorber sachets should be kept tightly sealed to prevent moisture absorption and loss of efficacy due to damage. Proper storage conditions ensure that the Dry Fast Desiccant Sachets maintains optimal performance until use.

Dry Fast Desiccant Sachets Precautions

When using the Dry Fast Desiccant Sachets, avoid direct contact with metal parts and prevent sharp objects from puncturing the packaging. Quick acting Desiccant should be used immediately and should not be exposed to air for extended periods to prevent premature moisture absorption and loss of efficacy. Maintaining a good seal and barrier properties within the packaging is crucial for ensuring the maximum effectiveness of the moisture absorber sachets. Furthermore, Quick acting Desiccant is for industrial use only and should not be used in food or pharmaceutical packaging.

Desiccant sachets Usage and Dosage

Under normal conditions, the recommended dosage of Desiccant sachets is 200g/m³. However, due to variations in packaging materials, application humidity, and storage and transportation conditions, CVCI will professionally customize the most appropriate usage and dosage plan for each customer, ensuring optimal moisture-proofing effectiveness while balancing cost and efficiency. CVCI also provides comprehensive technical guidance and application support, ensuring customers use Desiccant sachetswith confidence and efficiency.

FAQs:

1. What are the appropriate applications for moisture absorber sachets?

Moisture absorber sachets is commonly used for storage, rust-proof packaging, and short-distance transportation of metal products such as machined parts, steel, gears, bearings, and molds. It is particularly well-suited for sealed environments requiring rapid dehumidification.

2. Will moisture absorber sachets leave residue or corrosion on metal surfaces after use?

No. Quick acting Desiccant is made of environmentally friendly, moisture-absorbing materials that are non-corrosive, release no harmful substances, and leave no residue on metal surfaces.

3. How do I determine the required amount of Quick acting Desiccant?

The amount of Quick acting Desiccant required depends on the packaging space, sealing properties, and ambient humidity. Under normal conditions, a basic usage of 200g/m³ is recommended. CVCI will also provide recommended Dry Fast Desiccant Sachets dosage and usage plans based on individual customer packaging volume and moisture-proofing requirements.

4. How should Dry Fast Desiccant Sachets be used?

Place Quick acting Desiccant directly inside the product packaging, keeping it in contact with air for effective use. It is recommended to use it in sealed packaging to ensure rapid and efficient moisture absorption.

Partners:

Collaborating with Fortune 500 companies allows CVCI to better understand its customers' true needs. Customers like BYD, Geely, and Sany Heavy Energy have reported in real-world projects that our anti-rust paper and oil not only reduce corrosion but also simplify operational processes. These real-world user experiences are the reason customers continue to choose CVCI.

Advanced Laboratory:

Our laboratory plays a crucial role in our product iterations. Each generation of Desiccant sachets undergoes rigorous laboratory testing. Performance improvements are reflected not only in data but also in customer feedback. Many customers report that the difference after use is truly visible.

Certifications:

With a wealth of patents, standards, and awards, CVCI has established a significant position in the anti-rust industry. From brake discs to bearings, from electronic components to stainless steel coils, CVCI's VCI anti-rust paper, oil, film, and moisture absorber sachets are widely used and trusted by customers. We are more than just a manufacturer; we are a key force driving the development of industry standards.