How Can Antistatic VCI Film Protect Power Modules in a Damp Warehouse?

2025-11-20 13:53When it comes to power modules, the immediate impression is often "electronic, precision, and afraid of water." Indeed, power modules contain circuit boards, copper foil, solder joints, and heat sinks—components highly sensitive to moisture and corrosion. If they get damp in a warehouse, poor contact, decreased insulation, and even short circuits or malfunctions may occur. Recently, many customers have asked us: Can China anti rust film replace traditional desiccant boxes and desiccants in such humid warehouses? Can we simply wrap the power modules and call it a day? This article will explain the principles of China anti rust film, its advantages, the real risks of humid environments, and practical suggestions step by step in a simple way, while also sharing our practical experience in exporting to Southeast Asia.

What is China anti rust film? Don't Just Think of It as Plastic Film

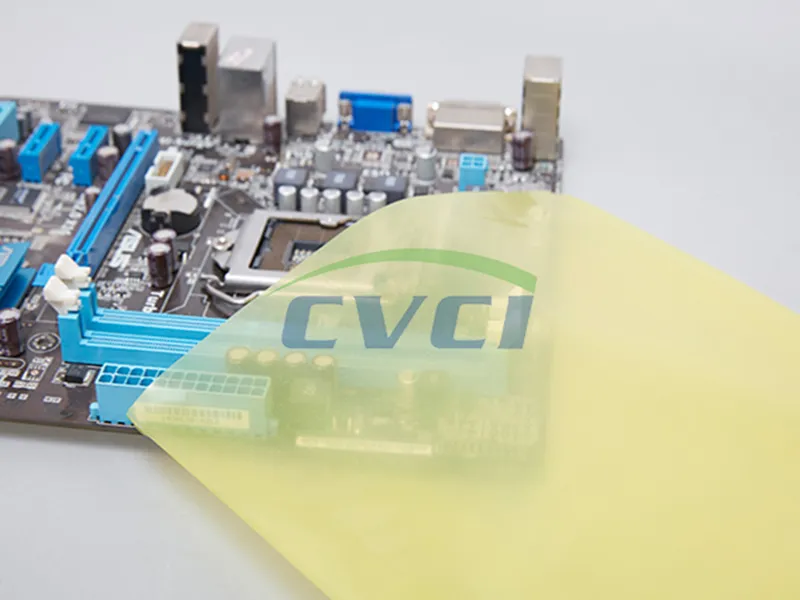

China anti rust film may sound like a very ordinary thing, but it is not the same as ordinary plastic film that only serves to keep out dust. Truly effective rust-preventing films often contain VCI (volatile corrosion inhibitors) or have special surface treatments. The working principle is simple yet ingenious: when you wrap a power module with Antistatic VCI Film, the rust-inhibiting molecules within the Antistatic VCI Film slowly evaporate, forming a molecular layer on the metal surface. This invisible protective film inhibits electrochemical reactions between the metal and air, moisture, and salt, thus reducing the likelihood of corrosion.

China anti rust film not only "blocks moisture," but it also "actively prevents rust." This, combined with ordinary sealing bags and desiccants, creates a synergistic effect greater than the sum of its parts.

What are the benefits of China anti rust film?

Practicality is what everyone cares about most. Here are some of the most intuitive and frequently cited benefits by customers, all of which we have repeatedly verified in real export projects:

Power modules contain solder joints, small copper pillars, and screw holes. Antistatic VCI Film's VCI molecules are small and can cover these hard-to-reach areas in a gaseous form, something traditional oil-based protection or desiccants alone cannot achieve.

Some protective methods (like oil-based rust inhibitors) leave an oil film on the surface, requiring customers to clean it upon receipt. China anti rust film-grade packaging leaves no oil residue that could affect electrical properties or appearance, making it more likely to be assembled directly, saving time and costs.

We have received feedback from many customers shipping to Vietnam, the Philippines, and Malaysia that traditional packaging showed a significantly higher probability of rust spots after 20+ days of sea freight compared to goods using our Antistatic VCI Film-grade packaging. It also provides more stable vapor phase protection in high humidity and high salt spray environments.

Furthermore, modern Antistatic VCI Film-grade packaging tends to be environmentally friendly and low in volatility, which helps meet the environmental and working environment requirements of international buyers, reducing disputes.

Is a damp warehouse really that bad?

Many people think of warehouses as just "places to store things" and don't constantly monitor temperature and humidity. However, several common factors in warehouses can quietly damage electronic components:

High relative humidity (RH): When humidity exceeds 60%–70%, condensation or moisture absorption occurs on metal surfaces, promoting electrochemical corrosion.

Condensation due to temperature differences: Warm days and cold nights create a large temperature difference between the inside and outside of packaging, causing condensation inside.

Salt spray or air pollutants: Warehouses near coastal or industrial areas contain salt or sulfides in the air, accelerating corrosion.

Prolonged storage and poor packaging ventilation: Prolonged storage or poor packaging ventilation can cause the protective layer to deplete and fail.

For power modules, corrosion is more than just an unsightly appearance—it alters the conductive path, corrodes solder joints, reduces insulation resistance, and can lead to noise, leakage, and even failure. Therefore, in a damp warehouse environment, simply hoping it won't break is clearly insufficient.

Performance of Rust-Proof Film in Humid Warehouses

In our projects packaging power modules for Southeast Asian clients, a common practice is a combination of Antistatic VCI Film + VCI rust-proof bags + desiccant. The main advantage of this combination is its layered protection: Antistatic VCI Film provides vapor phase protection and localized isolation, the rust-proof bags enhance overall sealing, and the desiccant absorbs excess moisture. Actual feedback shows that:

After 30 days of sea freight and 2 weeks of storage at the destination port, the appearance and solder joints of power modules protected by this combination show almost no change;

Under the same conditions, goods packaged with only desiccant or ordinary packaging have a significantly higher probability of developing rust spots;

Customers prefer "clean-free, ready-to-assemble" goods, saving preparation time before acceptance.

These conclusions are based on extensive shipping records and customer feedback, and are particularly effective in humid and hot markets such as Vietnam, Malaysia, and the Philippines.

Practical Recommendations for Packaging and Warehousing

Cleaning and Pre-treatment: Before shipping, thoroughly clean the surface of the power module to remove residual flux and oil stains. A clean surface promotes even adhesion of VCI molecules.

Drying: Use an air gun or hot air box to dry deep holes and interfaces to prevent moisture from being trapped during packaging.

Inner Layer Rust-Proof Film: Tightly wrap the power module with VCI rust-proof film, ensuring coverage of every interface and critical metal surface.

Outer Layer Rust-Proof Bag: Place the rust-proof film-wrapped module into a VCI rust-proof bag and vacuum-seal or seal it.

Adding Appropriate Desiccant: Place appropriately sized desiccant inside the bag or box to help control relative humidity.

Labeling and Storage: Label the rust-proofing treatment date and precautions on the box. Store boxed goods in a dry corner of the warehouse, away from doors, windows, and exterior walls.

This process is not particularly difficult, but it is essential to write the steps into the SOP (Standard Operating Procedure) before shipping and provide training to warehouse personnel to significantly reduce shipping risks.

Cost, Environmental Protection, and Customer Communication

Many people ask if using Antistatic VCI Film will increase costs. In the short term, there might be a slight increase, but from a long-term perspective: Customers receive rust-free products, reducing returns, customer complaints, and rework costs—these "hidden costs" often far exceed the material cost itself. Furthermore, receiving "clean-free, ready-to-assemble" products increases customer satisfaction and helps build long-term partnerships. If customers receive goods with oil stains or other defects requiring cleaning, their satisfaction may be lower. The environmentally friendly VCI materials used in CVCI are more readily accepted by international buyers, facilitating access to the European, American, and Southeast Asian markets. Therefore, in the long run, using Antistatic VCI Film doesn't result in significant cost waste.

Antistatic VCI Film is highly effective in protecting power modules.

Rust-preventive films (especially those with Antistatic VCI Film) are highly effective in protecting power modules in humid warehouses. Antistatic VCI Film provides vapor phase protection, covers small gaps, requires no cleaning, does not affect subsequent assembly, and performs excellently in sea freight and high-humidity environments. The safest approach is to combine Antistatic VCI Film and VCI rust-preventive bags with desiccants, and establish standardized cleaning and packaging procedures.

CVCI's export experience in the Southeast Asian market shows that high-humidity countries like Vietnam, Malaysia, and the Philippines have the highest acceptance of this combined protection method, and customer feedback is the most consistent. If your products require long-distance sea freight or extended warehousing, we strongly recommend including Antistatic VCI Film in your shipment standards.

If you are interested in our Antistatic VCI Film, rust-preventive liquid, or comprehensive rust prevention solutions, please feel free to contact us at cvci-gaoxiu@chinavci.com. You can schedule a visit to our factory to see our production line, or discuss your products, storage environment, and specific problems with our technical team. We are happy to customize solutions to meet your needs; whatever rust problems you want to solve, we can provide professional, reliable, and practical advice.