- Home

- >

News

Heat shrink film can be used for long-term anti-rust packaging of various metal equipment.

Using VCI emitter box for rust prevention, you will find that the metal parts are very clean and there is no oil or residue. VCI emitter box is particularly suitable for metal rust prevention in enclosed spaces, especially in clean environments.

In metal packaging, when facing those uneven metal products with complex threads, it is difficult for traditional anti-rust methods to cover every corner, and the placement of anti-rust powder may also leak key parts. So, how does anti rust film protect these irregular metal products from rust?

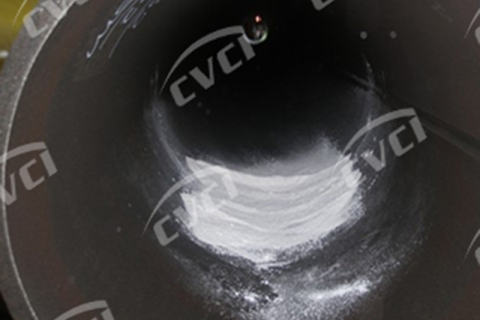

VCI Powder For Metal from CVCI can be flexibly used in a variety of enclosed spaces such as large-scale equipment, cavities, and pipelines.

CVCI has established a sound quality control system. From the procurement of raw materials to the production process, there are strict implementation standards in every link.

CVCI's anti rust oil can protect ferrous metals. The solvent-based formula will evaporate naturally after application, leaving a thin layer of protective coating.

The VCI plastic market is increasingly developing rapidly in a safer and more environmentally friendly direction. CVCI can customize VCI plastic according to the special needs of customers.

The VCI anti rust white powder produced by CVCI is a high-efficiency vapor-phase anti-rust powder designed for complex structures, with excellent gasification, diffusion and adsorption properties.

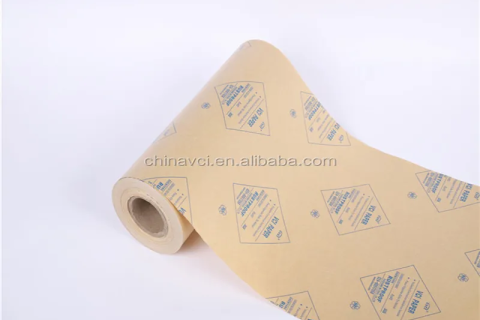

Now more and more export companies choose VCI steel wrap to protect steel, so why do more and more export companies choose VCI steel wrap to protect steel? Let's take a look together!

When using antirust paper packaging, it is necessary to ensure that the surface of the packaged electromechanical parts is clean and free of impurities.

VCI packaging paper can continuously release corrosion-inhibiting molecules in a confined environment, forming a stable protective film on the surface of the steel, and the anti-rust cycle can meet the long-term storage needs.

Wind turbine gears are highly valuable and require extremely high machining precision. Corrosion, if it occurs, directly impacts the equipment's lifespan and operating efficiency.