- Home

- >

- News

- >

- Product News

- >

News

CVCI can also provide customized services, which can adjust the parameters of the safe VCI film according to the size and shape of the sensor.

Metal surface corrosion is particularly problematic during long-term storage, cross-border transportation, or humid environments. Choosing the right rust prevention solution for this large equipment is crucial.

The VCI stretch film anti rust we produce is particularly suitable for use with anti rust oil to make anti-rust packaging for engine blocks.

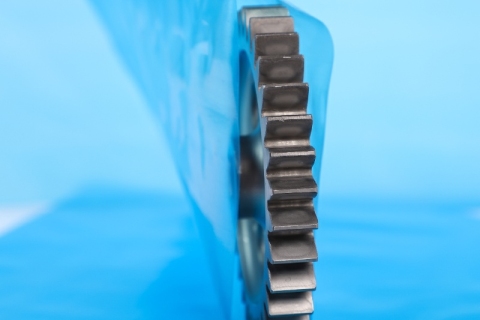

The VCI steel wrap we produce will not have any residue on the surface of the steel after the film is torn.

But our safe VCI film is different. It can be applied to a variety of metals such as steel, copper, and aluminum.

Once rust occurs, it not only deteriorates the appearance of the steel plate but can also affect other properties.

As a professional anti-rust film manufacturer, CVCI will continue to leverage its advanced production capabilities and comprehensive quality assurance system to provide highly effective, environmentally friendly, and cost-effective China Safe VCI Film products to customers worldwide.

To effectively delay rust and ensure product quality, applying china water based antirust fluid to the metal surface is an excellent option.

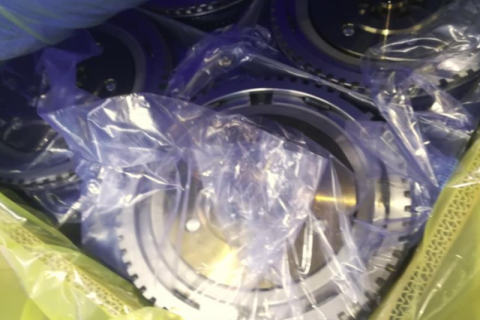

Antistatic VCI Film, with its superior protective performance and convenient operation, has gradually become the preferred packaging solution for large machine tools for export.

Preventing rust during these long sea transport periods is a crucial issue.

Combined with the above analysis, it can be concluded that in container transportation, water absorbent paper can reduce the risk of corrosion caused by humidity and condensate.

Our anti-rust oil has passed three international certifications of ROHS, SGS, and REACH.