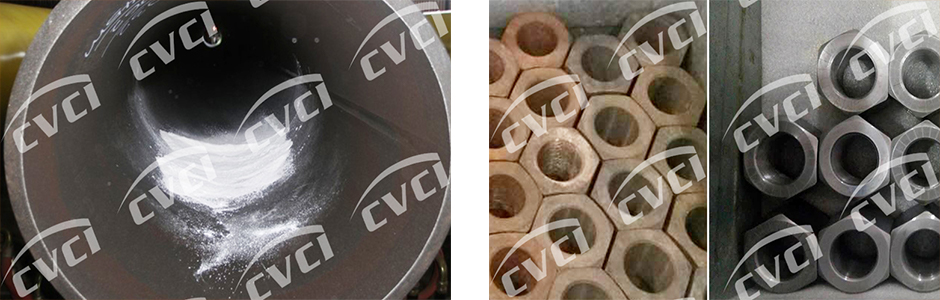

Equipment Manufacturing

With its profound anti-rust technology accumulation and rich industry experience, CVCI provides systematic anti-rust protection solutions for customers in various fields. We deeply analyze customers' personalized needs for material characteristics, processing technology, storage and transportation environment, and provide full-process services from solution design to on-site construction to ensure that products are reliably protected throughout the supply chain.

Energy equipment field

GE Energy, Dongfang Steam Turbine: Develop residual gas phase anti-rust technology for precision parts such as gas turbine blades and rotors to meet the long-term storage needs in high temperature and high humidity environments.

Siemens: Customize conductive VCI materials to ensure that metal parts of electrical cabinets are rust-proof without affecting electromagnetic compatibility.

Engineering machinery field

Sany Heavy Industry, Zoomlion Heavy Industry: Develop an anti-rust system for the inner wall of hydraulic pipelines of engineering machinery to solve the problem of condensed water corrosion during overseas transportation.

Haitian Precision: Special anti-rust wax for machine tool guide rails to achieve zero-contact protection of machined surfaces.

Intelligent manufacturing field

Siasun Robotics: Degradable anti-rust film for joint bearings of collaborative robots, which not only ensures protection but also meets the requirements of clean workshops.

Mitsubishi Electric: Ultra-thin VCI protection solution for metal frames of semiconductor equipment, with a thickness of only 0.03mm, which does not affect precision assembly.

Five reasons to choose CVCI:

Industry-specific solutions: 300+ case databases from different industries support precise solution design

Full-process service: one-stop solution from laboratory to shelf

Military-grade standards: some solutions are derived from the transformation of aerospace equipment protection technology

Global service network: technical service centers have been established in 12 countries

Continuous innovation: annual R&D investment accounts for more than 8%, and 80+ related patents are held

Typical service cases of anti-rust

The complete set of anti-rust solutions provided for a certain type of gas turbine of Dongfang Steam Turbine extended the protection period of its units exported to Indonesia in the marine environment from 3 months to 18 months.

Helped Sany Heavy Industry to reduce the comprehensive cost of export packaging of excavators by 35%, and the customer was rated as "China Export Quality and Safety Demonstration Enterprise".

The Siasun Robot collaborative manipulator solved the rust problem of joint bearings in sea transportation through our solution, and the overseas customer complaint rate was zero.

CVCI is providing intelligent anti-rust protection services to more than 500 industrial customers around the world. We look forward to protecting your product value with professionalism!