Is Antirust Film Safe For Electronic Components?

2025-05-24 15:04The most feared thing about electronic components is moisture, oxidation, and corrosion. Sometimes, if you are not careful during transportation, when the equipment reaches the customer, the solder joints will turn black and the metal feet will oxidize, which is really not worth the loss. The emergence of antistatic vci film just solves this problem. Antistatic vci film releases invisible anti-rust factors, and can form an invisible protective film without contacting the metal surface, which can effectively isolate moisture, oxygen and corrosive ions in the air. More importantly, these anti-rust factors are volatile. Once the package is opened, they will automatically dissipate, will not remain on the electronic components, and will not affect the conductivity or subsequent assembly process.

Many of our customers use VCI film to package circuit boards, IC chips, connectors, power tools, motor parts and other products. The anti-rust cycle can be up to 2 years. It is safe and pollution-free, leaving no traces, and you can never leave it after using it once.

CVCI has focused on the development and production of VCI series materials for many years. Antistatic vci film is one of our products with the most stable sales and the highest customer satisfaction. The customized antirust film we produce adopts multi-layer co-extrusion blown film technology, combined with high-efficiency volatile rust inhibitors, which can provide long-term protection for various metals such as steel, copper, aluminum alloy, etc., and is particularly suitable for the high requirements of cleanliness and safety in the electronics industry.

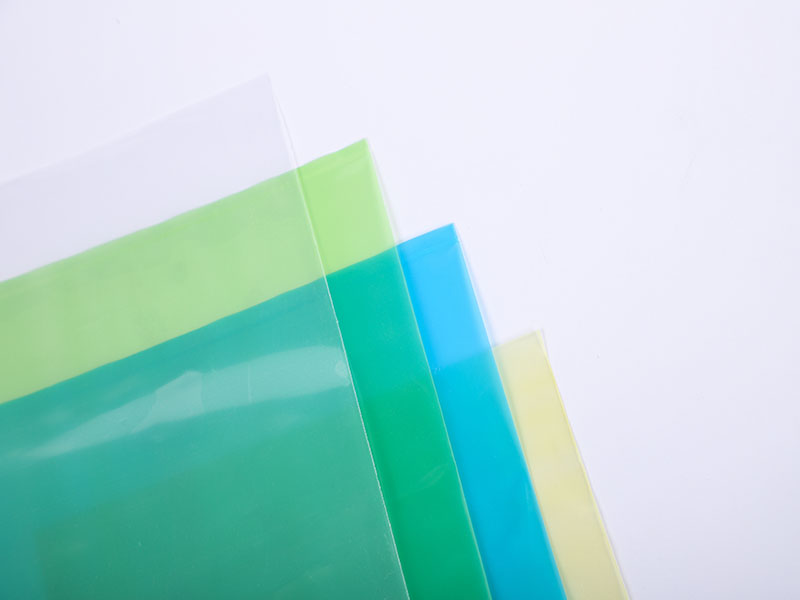

Our customized antirust film has uniform thickness, high transparency and good flexibility. It can not only directly wrap the product, but also be made into various packaging forms according to customer requirements to facilitate the needs of different customers. The surface of customized antirust film is clean, oil-free, dust-free, and crumb-free, which can effectively avoid static adsorption of foreign matter and keep sensitive components in the cleanest state.

In terms of production, we have a number of advanced blown film production lines and supporting packaging equipment, with an annual output of more than 4000 tons of various customized antirust films, supporting a variety of colors, sizes, and printing customization. All products have passed ROHS, REACH and other certifications, and have passed rigorous salt spray tests and anti-rust performance tests.

The antistatic vci film we produce is exported to Europe, America, Southeast Asia, the Middle East and other regions. It is widely used in electronics, electrical, precision instruments, auto parts, molds, mechanical equipment and other fields, and has accumulated rich application cases and customer praise.

If you are worried about the transportation and storage of exported electronic products, or looking for a more environmentally friendly, safer and smarter way to prevent rust, you might as well try our antistatic vci film. It not only protects your products from being in danger, but also adds a sense of professionalism and technology to your packaging.

If you have sample needs, or want to visit our production workshop and anti-rust laboratory, please feel free to contact us. We are very happy to provide you with detailed information and technical support. Don't let electronic components rust, give them an invisible layer of peace of mind protection!